- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 23:13

Back to list

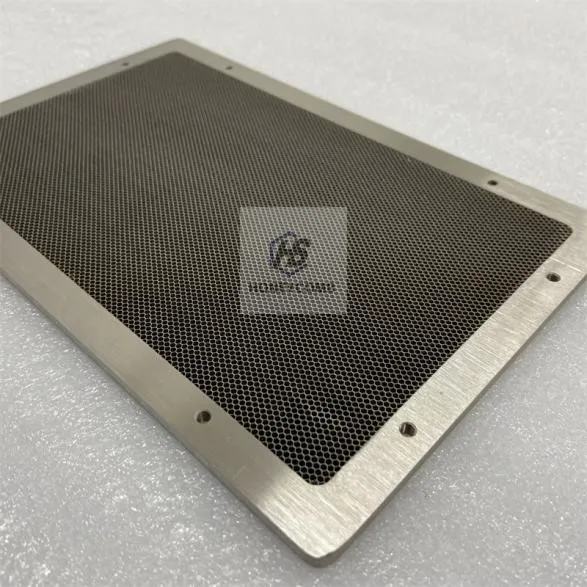

maf air fow straightener

Advanced honeycomb design in wind tunnel methodologies has profoundly reshaped the landscape of aerodynamic testing and development. This innovative design framework harnesses the structural integrity and efficiency of nature's honeycomb pattern, optimizing airflow and enhancing testing precision within wind tunnel environments.

In terms of professional expertise, the development and application of honeycomb wind tunnel designs demand a rigorous understanding of fluid dynamics, material science, and structural engineering. Specialists in these fields corroborate this design's efficacy through extensive simulations and prototype examinations, which confirm its advantages in creating more linear flows and minimizing eddies. The authoritative stance of honeycomb designs is further validated by their adoption in high-end facilities worldwide. Testing laboratories and engineering firms prioritize this approach to enhance their experimental accuracy and output quality. This widespread acceptance underscores the design's trustworthiness and reliability as a modern solution in the aerodynamic testing domain. Adopting the honeycomb design framework demonstrates a commitment to advancing aerodynamic research and development. Organizations implementing these designs affirm their pursuit of excellence in engineering innovation and environmental stewardship. The design's capacity to contribute to sustainable practices is another layer of its appeal, as it reduces the materials needed for construction while boosting efficiency and output. Ultimately, the honeycomb design in wind tunnel applications serves as a testament to the union of natural inspiration and engineering prowess. Its successful integration into testing protocols marks a significant evolution in aerodynamic analysis, supporting industries committed to technological advancement and ecological responsibility. By embracing such pioneering designs, the future of wind tunnel testing promises greater accuracy, deeper insights, and a departure from limitations previously encountered in traditional methods.

In terms of professional expertise, the development and application of honeycomb wind tunnel designs demand a rigorous understanding of fluid dynamics, material science, and structural engineering. Specialists in these fields corroborate this design's efficacy through extensive simulations and prototype examinations, which confirm its advantages in creating more linear flows and minimizing eddies. The authoritative stance of honeycomb designs is further validated by their adoption in high-end facilities worldwide. Testing laboratories and engineering firms prioritize this approach to enhance their experimental accuracy and output quality. This widespread acceptance underscores the design's trustworthiness and reliability as a modern solution in the aerodynamic testing domain. Adopting the honeycomb design framework demonstrates a commitment to advancing aerodynamic research and development. Organizations implementing these designs affirm their pursuit of excellence in engineering innovation and environmental stewardship. The design's capacity to contribute to sustainable practices is another layer of its appeal, as it reduces the materials needed for construction while boosting efficiency and output. Ultimately, the honeycomb design in wind tunnel applications serves as a testament to the union of natural inspiration and engineering prowess. Its successful integration into testing protocols marks a significant evolution in aerodynamic analysis, supporting industries committed to technological advancement and ecological responsibility. By embracing such pioneering designs, the future of wind tunnel testing promises greater accuracy, deeper insights, and a departure from limitations previously encountered in traditional methods.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025