- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 16, 2025 00:29

Back to list

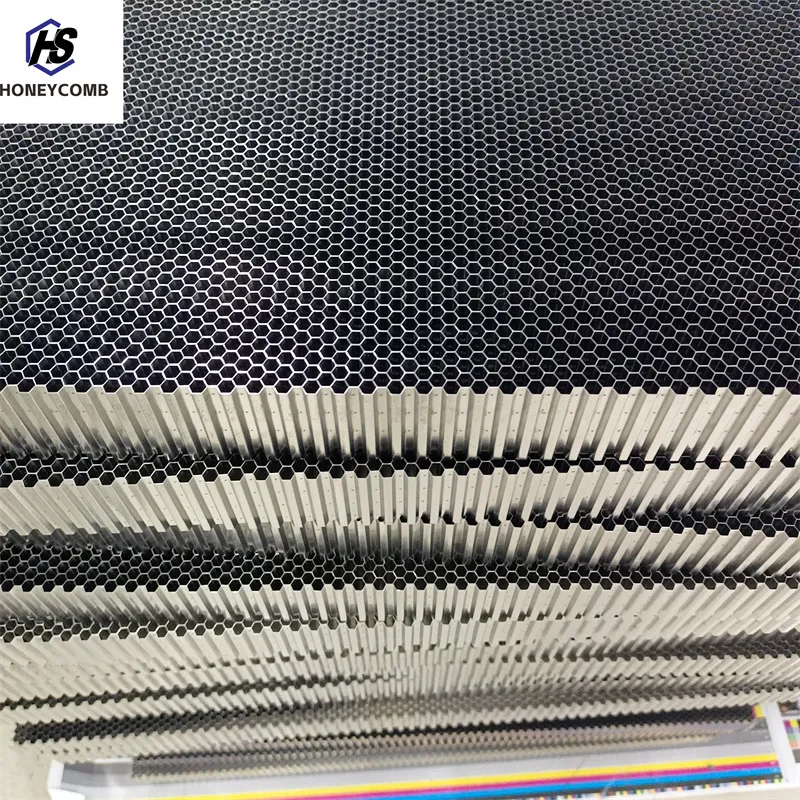

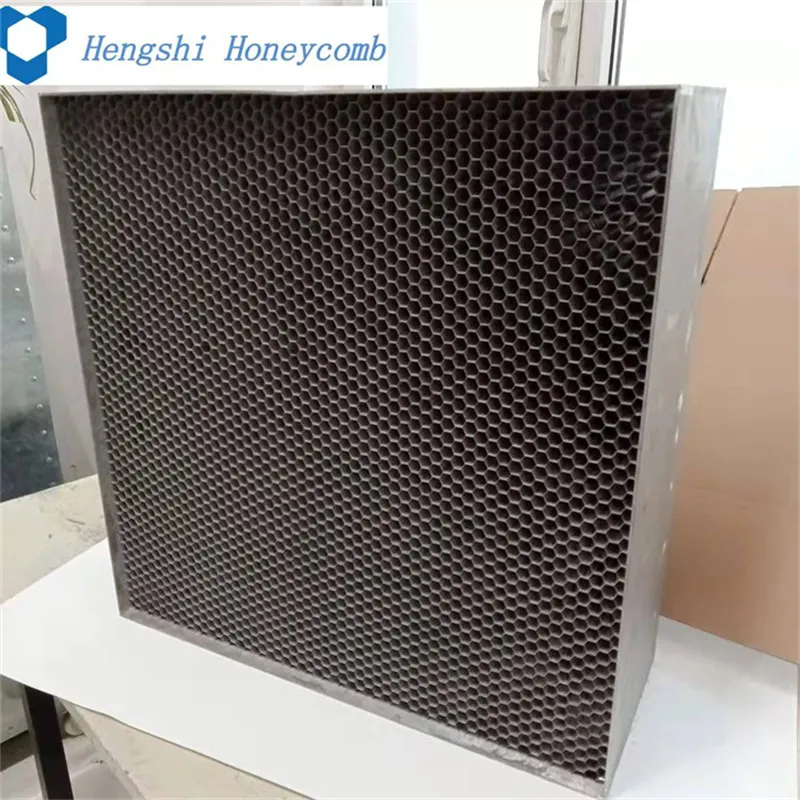

20mm Core Size Stainless Steel Honeycomb Core Panel - Customized for Wind Tunnel Applications

Crafting your own DIY air rectifier can be both a rewarding and intellectually stimulating project. Air rectifiers, known as raddrizzatore d'aria in Italian, are devices designed to streamline air flow, improving efficiency and reducing energy consumption in various applications. This guide delves into the intricate world of DIY air rectifiers, shedding light on the process, benefits, and potential challenges, ensuring you emerge as a well-informed enthusiast in this specialized field.

Assembly should be approached with precision and care, as inaccuracies can lead to inefficiencies or even system malfunctions. Each vane must be positioned at the correct angle, and assembly should be secured to prevent unwanted movement during operation. This stage offers a valuable opportunity to apply trusted techniques and practices honed over years of experience in related fields such as manufacturing or automotive industries. Once assembled, the rectifier must be meticulously tested to ensure its functionality meets the desired specifications. Testing can involve both controlled experiments, using wind tunnels or similar setups, and practical tests within the intended application environment. Data collected during these tests are invaluable for adjustments and improvements. The benefits of a DIY air rectifier are not merely limited to the satisfaction of creating a bespoke piece of equipment that directly contributes to efficiency. It also opens avenues for continuous innovation. As technology and materials evolve, so too can your designs. Additionally, customizing air rectifiers allows for a tailored approach not typically possible with off-the-shelf solutions, potentially offering superior performance and longevity for your specific needs. However, the journey is not without challenges. The intricacies of fluid dynamics and the precision required in construction can be daunting. Thankfully, a plethora of resources, from academic journals to online communities of engineers and DIY enthusiasts, can provide valuable support and guidance. Building a network of like-minded individuals can facilitate knowledge exchange and offer solutions to common hurdles faced in the DIY rectification process. In conclusion, engaging in the construction of a DIY air rectifier not only augments your understanding of air dynamics but also solidifies your stance as an authority in this niche. By merging empirical knowledge with hands-on experience, one can achieve a level of trustworthiness and expertise that is highly respected in technical communities. Whether for personal satisfaction or a professional pursuit, building an air rectifier is a commendable endeavor that showcases the pioneering spirit of innovation and expertise in the realm of airflow management.

Assembly should be approached with precision and care, as inaccuracies can lead to inefficiencies or even system malfunctions. Each vane must be positioned at the correct angle, and assembly should be secured to prevent unwanted movement during operation. This stage offers a valuable opportunity to apply trusted techniques and practices honed over years of experience in related fields such as manufacturing or automotive industries. Once assembled, the rectifier must be meticulously tested to ensure its functionality meets the desired specifications. Testing can involve both controlled experiments, using wind tunnels or similar setups, and practical tests within the intended application environment. Data collected during these tests are invaluable for adjustments and improvements. The benefits of a DIY air rectifier are not merely limited to the satisfaction of creating a bespoke piece of equipment that directly contributes to efficiency. It also opens avenues for continuous innovation. As technology and materials evolve, so too can your designs. Additionally, customizing air rectifiers allows for a tailored approach not typically possible with off-the-shelf solutions, potentially offering superior performance and longevity for your specific needs. However, the journey is not without challenges. The intricacies of fluid dynamics and the precision required in construction can be daunting. Thankfully, a plethora of resources, from academic journals to online communities of engineers and DIY enthusiasts, can provide valuable support and guidance. Building a network of like-minded individuals can facilitate knowledge exchange and offer solutions to common hurdles faced in the DIY rectification process. In conclusion, engaging in the construction of a DIY air rectifier not only augments your understanding of air dynamics but also solidifies your stance as an authority in this niche. By merging empirical knowledge with hands-on experience, one can achieve a level of trustworthiness and expertise that is highly respected in technical communities. Whether for personal satisfaction or a professional pursuit, building an air rectifier is a commendable endeavor that showcases the pioneering spirit of innovation and expertise in the realm of airflow management.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025