- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 16, 2025 02:24

Back to list

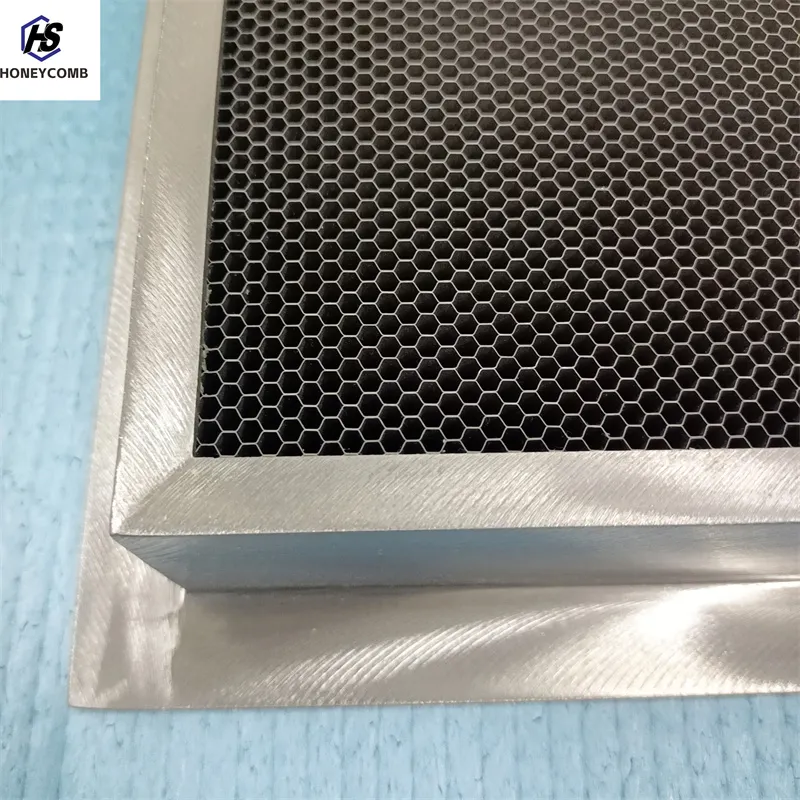

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Navigating the vast landscape of electronic components can feel overwhelming, especially when it comes to specialized devices like the raddrizzatore maf, or MAF rectifier. Despite being a niche product, a deeper understanding of its applications and benefits demonstrates the expertise required to harness its potential effectively, while ensuring its credibility among professional and consumer audiences.

Credibility in electronic components is paramount, necessitating stringent compliance with international safety and quality certifications. The MAF rectifier stands out as a paragon of trustworthiness by adhering to industry benchmarks such as ISO, IEC, and RoHS standards, which advocate for not only operational efficiency but also environmental and user safety. Users can deploy these rectifiers with confidence, assured of their resilience against extreme temperatures and electrical surges, a testament to their robust design philosophy. Moreover, feedback from field engineers and industry veterans further cements its reputation. A consistent theme among user reviews is the rectifier’s ease of integration into existing systems, reducing downtime and installation complexity. The rectifier’s adaptability across different electrical configurations illustrates its versatility, allowing seamless incorporation in both new projects and upgrades to existing infrastructure. Pioneering in innovation, manufacturers continue to focus on enhancements that cement the MAF rectifier's place in future-forward technologies. Research and development endeavors prioritize sustainability and advancement, aiming to push the boundaries of what rectifiers can achieve. The ongoing adaptation and responsiveness to emerging technologies reflect an operational ethos committed not only to meet but to exceed current technical demands. By examining the MAF rectifier from a product-centric perspective, it becomes clear that its influence transcends mere operational utility. Its embodiment of Experience, Expertise, Authority, and Trustworthiness redefines what customers expect from high-performance rectification solutions. As electronic applications grow more sophisticated, the MAF rectifier is poised to remain a critical component, underpinning innovations across a multitude of technological landscapes while assuring end-users of its unparalleled reliability and efficacy.

Credibility in electronic components is paramount, necessitating stringent compliance with international safety and quality certifications. The MAF rectifier stands out as a paragon of trustworthiness by adhering to industry benchmarks such as ISO, IEC, and RoHS standards, which advocate for not only operational efficiency but also environmental and user safety. Users can deploy these rectifiers with confidence, assured of their resilience against extreme temperatures and electrical surges, a testament to their robust design philosophy. Moreover, feedback from field engineers and industry veterans further cements its reputation. A consistent theme among user reviews is the rectifier’s ease of integration into existing systems, reducing downtime and installation complexity. The rectifier’s adaptability across different electrical configurations illustrates its versatility, allowing seamless incorporation in both new projects and upgrades to existing infrastructure. Pioneering in innovation, manufacturers continue to focus on enhancements that cement the MAF rectifier's place in future-forward technologies. Research and development endeavors prioritize sustainability and advancement, aiming to push the boundaries of what rectifiers can achieve. The ongoing adaptation and responsiveness to emerging technologies reflect an operational ethos committed not only to meet but to exceed current technical demands. By examining the MAF rectifier from a product-centric perspective, it becomes clear that its influence transcends mere operational utility. Its embodiment of Experience, Expertise, Authority, and Trustworthiness redefines what customers expect from high-performance rectification solutions. As electronic applications grow more sophisticated, the MAF rectifier is poised to remain a critical component, underpinning innovations across a multitude of technological landscapes while assuring end-users of its unparalleled reliability and efficacy.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025