- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 05, 2025 01:20

Back to list

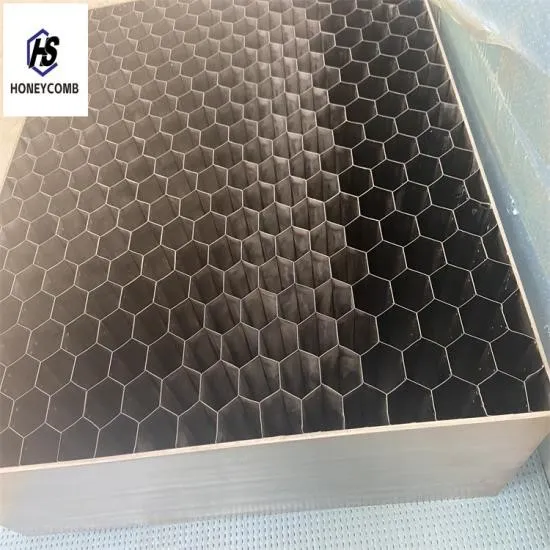

rectificador de flujo de aire de nido de abeja

Airflow rectifiers, particularly those utilizing a honeycomb design, have become a cornerstone in modern industrial and environmental applications. These devices are engineered to refine and streamline air currents, benefiting a myriad of operations from automotive to electronics cooling. The honeycomb configuration is noted for its ability to induce laminar flow by reducing turbulence and enhancing the uniformity of airflow.

In recent years, the integration of honeycomb airflow rectifiers into everyday systems such as HVAC is gaining momentum. This reflects an industry shift towards optimizing energy use and reducing carbon footprints. The fine control over airflow translates to more consistent climate control, which in turn contributes to energy savings and reduced operational costs. However, the commitment to utilizing these structures extends beyond just efficiency. The ecological impact is also a noteworthy facet. Honeycomb designs, by promoting efficient airflow, reduce the overall energy demands of mechanical systems. For industries aiming to align with sustainability goals, this reduction represents a significant achievement in minimizing environmental impact. Furthermore, the adoption of honeycomb airflow rectifiers is leveraging advanced materials science. Modern constructions often include alloys or composites that offer enhanced resistance to degradation and environmental stresses. This advancement ensures that rectifiers provide long-term, reliable performance, safeguarding investments and extending product lifespans. For businesses and industries exploring the adoption or upgrade of their systems, the honeycomb airflow rectifier presents a compelling choice. Its traditional efficiency is now paired with cutting-edge developments in material engineering, extending its utility and fortifying its position as a critical tool in achieving both operational efficiency and environmental responsibility. In summary, airflow rectifiers featuring honeycomb designs represent a synthesis of practical efficiency and innovative engineering. From enhancing industrial processes to contributing to sustainable development, these devices embody the confluence of technical expertise and ecological mindfulness. Their continued evolution and integration into diverse applications underscore their importance as essential assets within contemporary systems seeking meticulous airflow management.

In recent years, the integration of honeycomb airflow rectifiers into everyday systems such as HVAC is gaining momentum. This reflects an industry shift towards optimizing energy use and reducing carbon footprints. The fine control over airflow translates to more consistent climate control, which in turn contributes to energy savings and reduced operational costs. However, the commitment to utilizing these structures extends beyond just efficiency. The ecological impact is also a noteworthy facet. Honeycomb designs, by promoting efficient airflow, reduce the overall energy demands of mechanical systems. For industries aiming to align with sustainability goals, this reduction represents a significant achievement in minimizing environmental impact. Furthermore, the adoption of honeycomb airflow rectifiers is leveraging advanced materials science. Modern constructions often include alloys or composites that offer enhanced resistance to degradation and environmental stresses. This advancement ensures that rectifiers provide long-term, reliable performance, safeguarding investments and extending product lifespans. For businesses and industries exploring the adoption or upgrade of their systems, the honeycomb airflow rectifier presents a compelling choice. Its traditional efficiency is now paired with cutting-edge developments in material engineering, extending its utility and fortifying its position as a critical tool in achieving both operational efficiency and environmental responsibility. In summary, airflow rectifiers featuring honeycomb designs represent a synthesis of practical efficiency and innovative engineering. From enhancing industrial processes to contributing to sustainable development, these devices embody the confluence of technical expertise and ecological mindfulness. Their continued evolution and integration into diverse applications underscore their importance as essential assets within contemporary systems seeking meticulous airflow management.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025