- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 13:25

Back to list

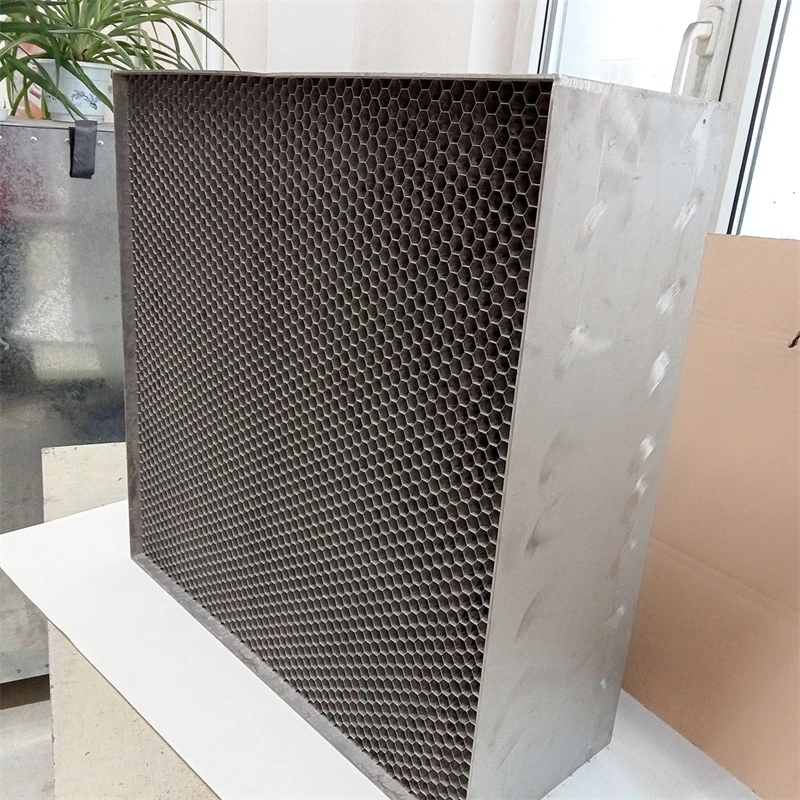

maf honeycomb screen

The MAF air rectifier, commonly known as the air flow sensor, plays a pivotal role in modern automotive technology. This device, though seemingly insignificant, ensures optimal engine performance and fuel efficiency. By measuring the air intake going into the engine, the MAF sensor provides data that allows the engine control unit (ECU) to balance and deliver the right mix of air and fuel to the combustion chamber.

Trust in a MAF sensor's operation is bolstered by adherence to stringent quality standards by manufacturers. Organizations that produce these sensors often undergo rigorous testing protocols to ensure that each unit functions as intended under various environmental conditions. This commitment to reliability not only instills confidence in consumers but establishes a benchmark in the industry for quality assurance. Moreover, authoritative automotive publications frequently stress the importance of investing in genuine parts. While cheaper, non-branded alternatives might seem appealing, their lack of durability and precision can result in frequent replacements and potential engine issues. Enthusiasts and experts alike consistently advise choosing OEM (Original Equipment Manufacturer) parts for longevity and peace of mind. Finally, the feedback loop of real-world experiences shared among vehicle owners plays a critical role in understanding the nuances of MAF sensor replacements and upgrades. Forums and user reviews offer invaluable insights into the practical aspects of sensor maintenance, from installation challenges to performance improvements. Listening to these voices helps both seasoned and novice drivers make informed decisions tailored to their specific vehicle needs. Ultimately, the MAF air rectifier's significance cannot be overstated. Its accurate functioning ensures that cars run efficiently, economically, and in an environmentally friendly manner. As technology continues to advance, we can only expect further innovations in this field, contributing to an era of smarter, more responsive automotive performance.

Trust in a MAF sensor's operation is bolstered by adherence to stringent quality standards by manufacturers. Organizations that produce these sensors often undergo rigorous testing protocols to ensure that each unit functions as intended under various environmental conditions. This commitment to reliability not only instills confidence in consumers but establishes a benchmark in the industry for quality assurance. Moreover, authoritative automotive publications frequently stress the importance of investing in genuine parts. While cheaper, non-branded alternatives might seem appealing, their lack of durability and precision can result in frequent replacements and potential engine issues. Enthusiasts and experts alike consistently advise choosing OEM (Original Equipment Manufacturer) parts for longevity and peace of mind. Finally, the feedback loop of real-world experiences shared among vehicle owners plays a critical role in understanding the nuances of MAF sensor replacements and upgrades. Forums and user reviews offer invaluable insights into the practical aspects of sensor maintenance, from installation challenges to performance improvements. Listening to these voices helps both seasoned and novice drivers make informed decisions tailored to their specific vehicle needs. Ultimately, the MAF air rectifier's significance cannot be overstated. Its accurate functioning ensures that cars run efficiently, economically, and in an environmentally friendly manner. As technology continues to advance, we can only expect further innovations in this field, contributing to an era of smarter, more responsive automotive performance.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025