- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 01, 2025 04:29

Back to list

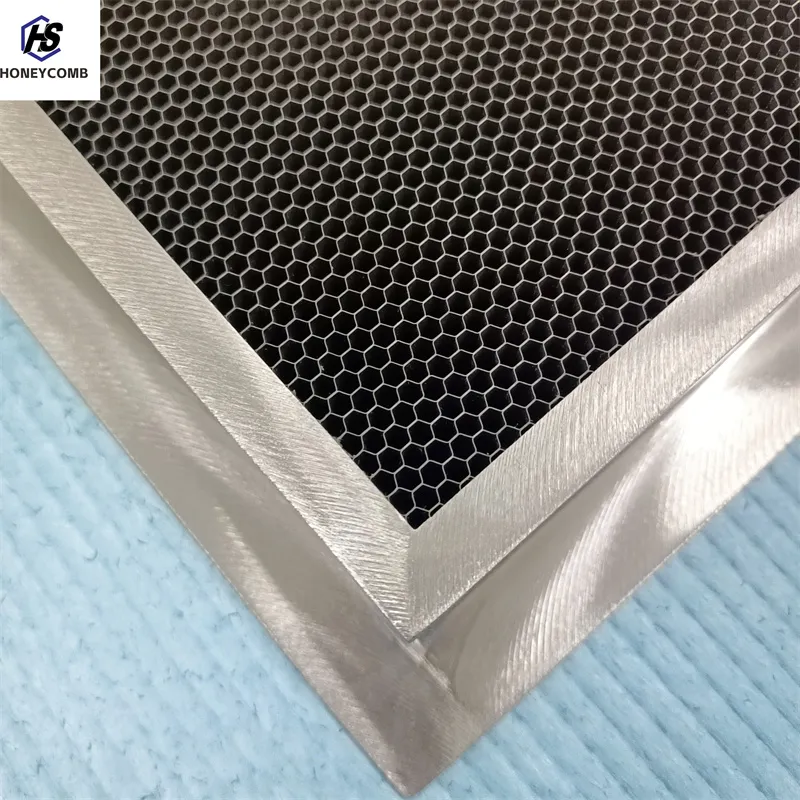

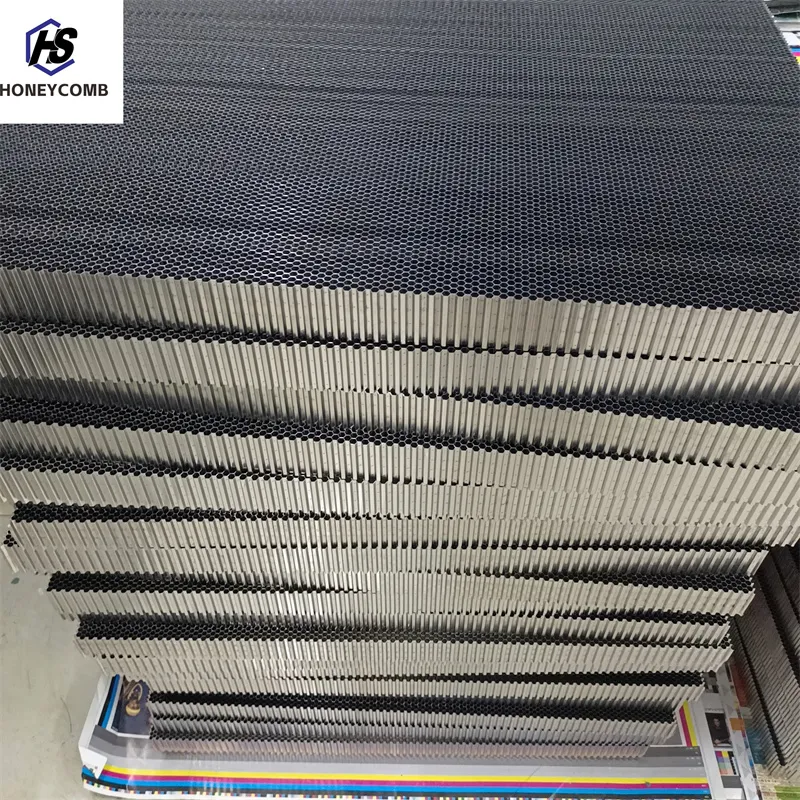

High Shielding Performance 2.0mm Cell Steel Honeycomb Vent For EMI/EMC/RF Shielded

In the rapidly evolving world of construction and design, materials that offer both robustness and versatility are prized. Enter the stainless steel honeycomb panel, a modern marvel that combines strength, aesthetics, and functionality, making it an indispensable choice for architects and builders alike.

Speaking on authority, industry leaders and specialists in architectural materials often endorse stainless steel honeycomb panels as sustainable solutions for modern construction challenges. This endorsement is based on a wealth of scientific research and real-world tests that confirm these panels’ ability to withstand significant force without deformation, their impressive fire-resistant properties, and their acoustic insulation capabilities. These attributes make them suitable for a range of applications, from residential buildings to commercial complexes and public infrastructure. Trustworthiness is further cemented by the panel’s track record in numerous high-profile projects worldwide. Many skyscrapers, stadiums, and airports incorporate stainless steel honeycomb panels, not only for their structural benefits but also for their aesthetic appeal. The panels can be customized with different finishes and textures, allowing architects creative freedom without compromising on performance. Moreover, sustainability is a growing concern in today’s world, and stainless steel honeycomb panels respond to this challenge. They can be produced using recycled materials and are themselves recyclable at the end of their life cycle, contributing to a circular economy. This aligns with environmental goals and green building certifications, making them an attractive option for eco-conscious projects. In conclusion, the stainless steel honeycomb panel represents a fusion of cutting-edge technology and practical application. Its ability to meet the demanding needs of modern architecture and construction, while offering a sustainable path forward, makes it a preferred choice for industry professionals. As more projects demand materials that deliver on promises of durability, efficiency, and environmental responsibility, these panels will continue to play a pivotal role in shaping the skylines and infrastructures of tomorrow.

Speaking on authority, industry leaders and specialists in architectural materials often endorse stainless steel honeycomb panels as sustainable solutions for modern construction challenges. This endorsement is based on a wealth of scientific research and real-world tests that confirm these panels’ ability to withstand significant force without deformation, their impressive fire-resistant properties, and their acoustic insulation capabilities. These attributes make them suitable for a range of applications, from residential buildings to commercial complexes and public infrastructure. Trustworthiness is further cemented by the panel’s track record in numerous high-profile projects worldwide. Many skyscrapers, stadiums, and airports incorporate stainless steel honeycomb panels, not only for their structural benefits but also for their aesthetic appeal. The panels can be customized with different finishes and textures, allowing architects creative freedom without compromising on performance. Moreover, sustainability is a growing concern in today’s world, and stainless steel honeycomb panels respond to this challenge. They can be produced using recycled materials and are themselves recyclable at the end of their life cycle, contributing to a circular economy. This aligns with environmental goals and green building certifications, making them an attractive option for eco-conscious projects. In conclusion, the stainless steel honeycomb panel represents a fusion of cutting-edge technology and practical application. Its ability to meet the demanding needs of modern architecture and construction, while offering a sustainable path forward, makes it a preferred choice for industry professionals. As more projects demand materials that deliver on promises of durability, efficiency, and environmental responsibility, these panels will continue to play a pivotal role in shaping the skylines and infrastructures of tomorrow.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025