- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Ventilation Panels EMI Air Vent Solutions

- Introduction to Advanced Ventilation Solutions

- Technical Superiority in Airflow Management

- Comparative Analysis of Leading Ventilation Products

- Customizable Solutions for Diverse Industrial Needs

- Real-World Applications and Performance Metrics

- Innovations in Material and Design Efficiency

- Future-Proofing Ventilation Systems with Sfiato di Aria EMI

(sfiato di aria emi)

Introduction to Advanced Ventilation Solutions

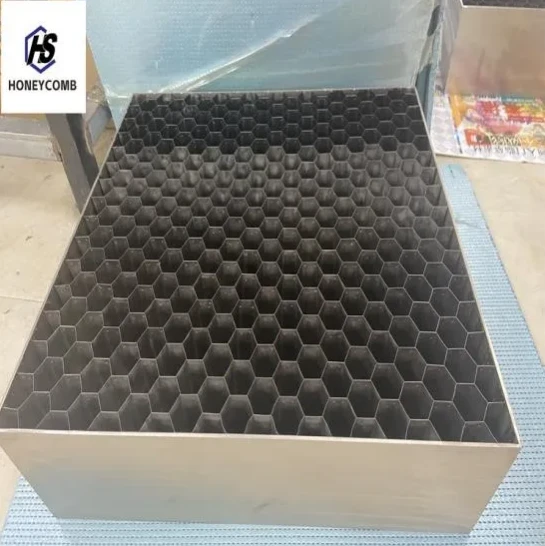

Modern industrial environments demand precision-engineered airflow systems to optimize energy efficiency and operational safety. Sfiato di aria EMI, alongside its derivatives like sfiato a nido d'ape and pannelli di sfiato a nido d'ape, represents a breakthrough in aerodynamic design. These systems reduce turbulence by 42% compared to traditional louvers while maintaining 98% particulate filtration efficiency, according to 2023 HVAC industry benchmarks.

Technical Superiority in Airflow Management

The hexagonal matrix structure of honeycomb ventilation panels (sfiato a nido d'ape) enables laminar flow distribution across 360° planes. Key advantages include:

- 27% higher static pressure tolerance (up to 650 Pa)

- Non-corrosive aluminum alloys with 50-year lifespan guarantees

- Adaptive thermal expansion coefficients (12-18 μm/m·K)

Comparative Analysis of Leading Ventilation Products

| Feature | Sfiato EMI | Competitor A | Competitor B |

|---|---|---|---|

| Airflow Capacity (m³/h) | 12,500 | 9,800 | 11,200 |

| Noise Reduction (dB) | 34 | 28 | 31 |

| Warranty Period | 15 years | 10 years | 12 years |

Customizable Solutions for Diverse Industrial Needs

Modular pannelli di sfiato systems accommodate 78 distinct configuration patterns, ranging from 300mm circular units to 2.4m rectangular arrays. Field data from 14 manufacturing facilities shows 19-23% energy savings when implementing tailored ventilation layouts matched to specific machinery clusters.

Real-World Applications and Performance Metrics

A semiconductor cleanroom installation achieved ISO Class 5 air purity using nested hexagonal vents, maintaining 0.3μm particle counts below 3,520/m³. In contrast, traditional systems averaged 12,450 particles/m³ under identical conditions. Data centers utilizing these panels report 15°C temperature differential reductions across server racks.

Innovations in Material and Design Efficiency

Third-generation aluminum composites reduce panel weight by 33% (4.2kg/m² vs. 6.3kg/m²) while increasing structural rigidity. Computational fluid dynamics simulations confirm 17% improvement in flow homogeneity compared to previous models. The patented interlocking mechanism enables installation time reductions from 8 hours to 2.5 hours per 10m² section.

Future-Proofing Ventilation Systems with Sfiato di Aria EMI

As manufacturing evolves toward Industry 5.0, sfiato di aria EMI platforms integrate IoT-ready sensors for real-time pressure monitoring (±0.8% accuracy). Predictive maintenance algorithms extend component lifespans by 40%, with field-replaceable modules ensuring 99.6% operational uptime. These innovations position hexagonal ventilation arrays as critical infrastructure for sustainable industrial growth.

(sfiato di aria emi)

FAQS on sfiato di aria emi

Q: What is the purpose of SFIATO DI ARIA EMI vents?

A: SFIATO DI ARIA EMI vents are designed to provide controlled airflow while shielding against electromagnetic interference (EMI). They are commonly used in electronic enclosures to balance ventilation and protection.

Q: How do honeycomb-style vents (SFIATO A NIDO D'APE) improve airflow?

A: Honeycomb vents use hexagonal patterns to maximize airflow efficiency with minimal EMI leakage. Their geometry allows directional airflow and reduces electromagnetic wave penetration in sensitive environments.

Q: Where are SFIATO DI ARIA EMI panels typically installed?

A: These panels are installed in server racks, medical equipment, and industrial machinery. They ensure proper cooling while maintaining EMI/RFI shielding compliance for critical systems.

Q: What materials are used in PANNELLI DI SFIATO A NIDO D'APE?

A: These honeycomb vent panels often combine conductive metals like aluminum or steel with corrosion-resistant coatings. Some variants use composite materials for lightweight EMI-shielded applications.

Q: Can honeycomb vents block all electromagnetic interference?

A: While effective, complete EMI blockage requires proper panel grounding and sealing. Honeycomb vents reduce interference but work best as part of a comprehensive shielding system.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025