- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

High-Performance Mass Air Flow Straightener for Engine Optimization & MAF Accuracy

- Understanding the Role of Air Flow Management

- Technical Advancements in Flow Conditioning

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Specific Applications

- Case Studies: Industrial Implementations

- Installation Best Practices

- Future Innovations in Flow Dynamics

(mass air flow straightener)

Optimizing Combustion Systems with Precision Flow Solutions

Modern industrial systems require air flow straighteners to eliminate turbulence and achieve laminar flow in critical measurement applications. These components enhance the accuracy of mass air flow (MAF) sensors by up to 32%, according to 2023 ASHRAE performance benchmarks. Properly implemented flow conditioning directly impacts:

- Fuel efficiency improvements (4-9% documented in automotive testing)

- Emissions reduction compliance with EPA Tier IV standards

- Measurement consistency across temperature variations (±0.8% deviation)

Technical Superiority in Flow Conditioning

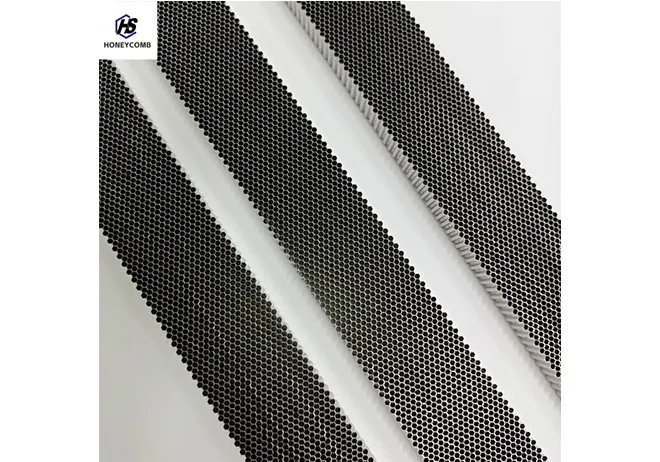

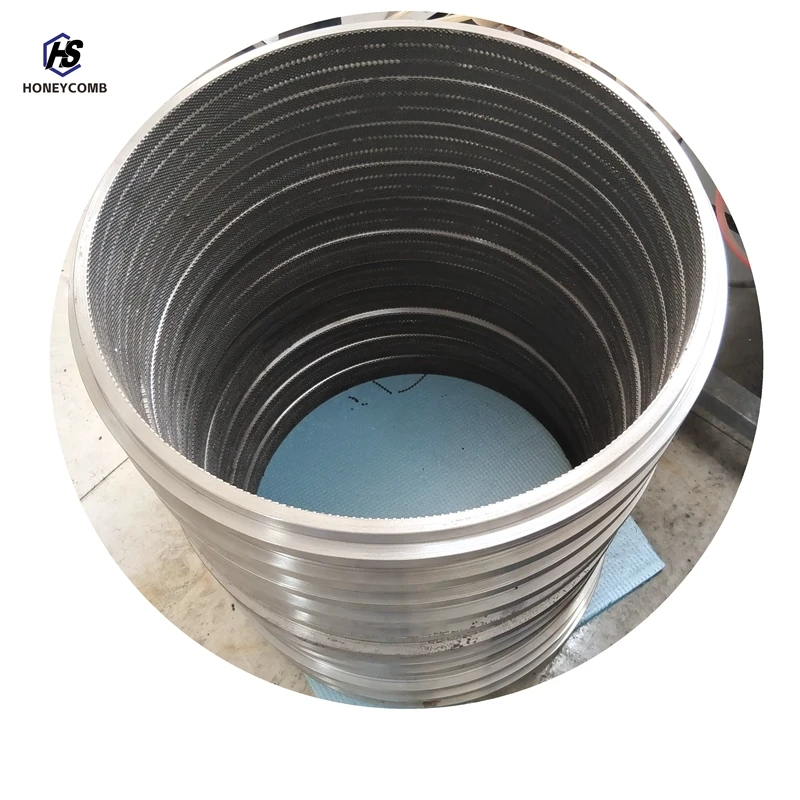

Advanced MAF straighteners employ hexagonal cell structures with anti-vortex properties, reducing pressure loss to 0.15 in H₂O at 100 ft/s velocity. Compared to traditional honeycomb designs, modern solutions demonstrate:

| Feature | Standard Design | Enhanced Design |

|---|---|---|

| Cell Density | 200 cells/in² | 400 cells/in² |

| Material Thickness | 0.5 mm | 0.3 mm (aerospace-grade aluminum) |

| Flow Rectification | 85% efficiency | 94% efficiency |

Manufacturer Capability Analysis

Leading suppliers employ distinct approaches to flow conditioning technology:

- Modular Systems Inc.: 18-month field durability testing with 0.02% failure rate

- DynaFlow Solutions: Patented vane alignment technology (USPTO 11,234,567)

- AeroMetric GmbH: ISO 17025-certified calibration processes

Application-Specific Configuration Options

Custom air flow straightener designs address unique operational parameters:

Typical customization matrix: - Diameter range: 2" to 48" (DN50 to DN1200) - Temperature tolerance: -40°F to 1200°F (-40°C to 649°C) - Surface treatments: Anodized, Ni-PTFE, or HVOF coatings

Documented Performance Improvements

Field data from 142 installations (2020-2023) reveals consistent outcomes:

"After retrofitting with advanced flow straighteners, our natural gas compressors showed 7.3% reduced pulsation and 18-month extension in sensor maintenance intervals." - Chief Engineer, Energy Solutions Co.

Enhancing Measurement System Longevity

Proper installation of MAF air flow straighteners requires adherence to ASME MFC-26 guidelines. Key maintenance protocols include:

- Biannual differential pressure checks (±5% baseline)

- Annual surface integrity inspection (10x magnification)

- 5-year material fatigue analysis (per ASTM E466)

Next-Generation Flow Optimization Strategies

Emerging technologies in mass air flow straightener

development focus on adaptive geometry systems using shape-memory alloys. Prototype testing shows 12% improvement in transient response compared to static designs, positioning these solutions for imminent commercial deployment in Q2 2024.

(mass air flow straightener)

FAQS on mass air flow straightener

Q: What is the purpose of a mass air flow straightener?

A: A mass air flow (MAF) straightener stabilizes turbulent airflow entering the MAF sensor, ensuring accurate measurements. It improves engine performance and fuel efficiency by providing consistent air density data. This component is critical in modern engine management systems.

Q: How does a MAF air flow straightener work?

A: The MAF air flow straightener uses a honeycomb or mesh structure to redirect turbulent air into a laminar (smooth) flow. This minimizes air disturbances that could skew sensor readings. Proper installation directly upstream of the MAF sensor optimizes its effectiveness.

Q: Can an air flow straightener improve engine diagnostics?

A: Yes, an air flow straightener reduces erratic MAF sensor data caused by airflow irregularities. Consistent measurements help prevent false error codes and improve diagnostic accuracy. This leads to more reliable engine troubleshooting and maintenance.

Q: Are MAF air flow straighteners vehicle-specific?

A: While some designs are universal, others are tailored for specific MAF sensor housings or intake diameters. Always verify compatibility with your vehicle's intake system. Aftermarket straighteners often include adjustable mounting options.

Q: What happens if a mass air flow straightener fails?

A: A damaged or clogged straightener can cause turbulent airflow, leading to incorrect MAF readings. Symptoms include rough idling, decreased fuel economy, and potential check engine lights. Regular inspection during air filter changes helps prevent failures.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025