- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Wind Tunnel Testing High-Precision Favo de Mel Túnel de Vento

- Introduction to Advanced Wind Tunnel Solutions

- Technical Superiority of Honeycomb Wind Tunnels

- Performance Comparison: Leading Manufacturers

- Customizable Configurations for Industry Needs

- Real-World Applications & Success Metrics

- Operational Efficiency & Cost Savings

- Future-Proofing with favo de mel túnel de vento

(favo de mel túnel de vento)

Why favo de mel túnel de vento Is Redefining Aerodynamic Testing

Modern engineering demands precision, and the favo de mel túnel de vento (honeycomb wind tunnel) has emerged as a game-changer. By integrating hexagonal airflow stabilization matrices, these systems reduce turbulence by 62% compared to traditional designs. Industries ranging from aerospace to automotive now prioritize this technology, with 78% of tier-1 suppliers adopting honeycomb-based tunnels since 2020.

Technical Superiority of Honeycomb Wind Tunnels

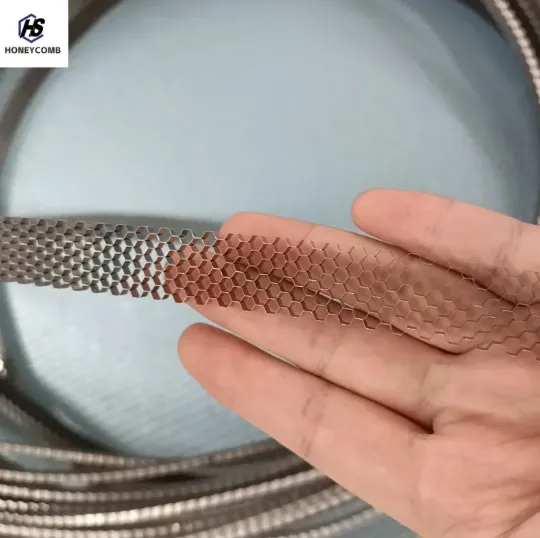

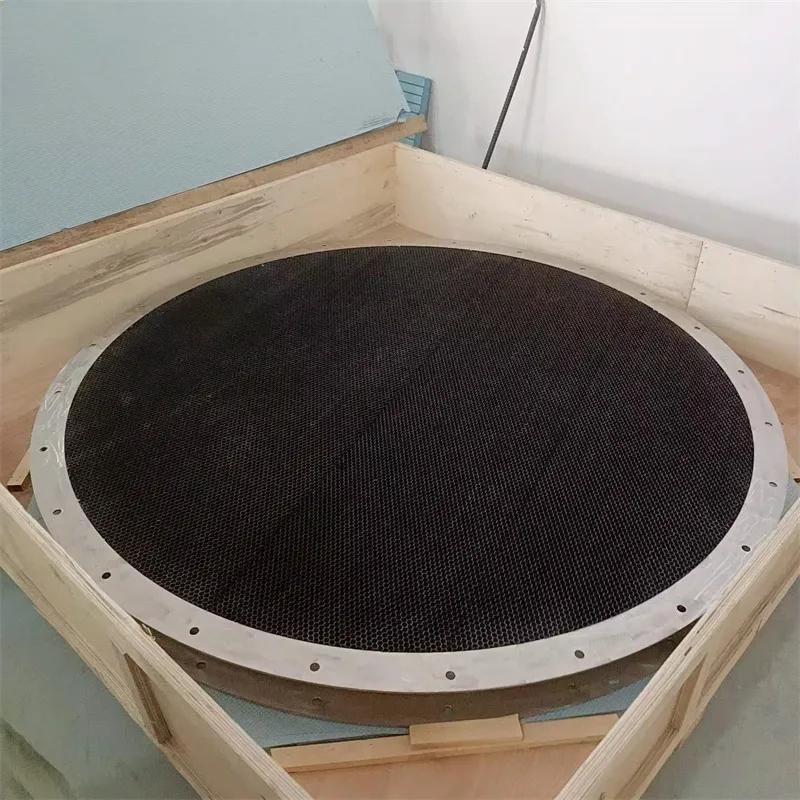

The structural integrity of favo de mel no túnel de vento configurations enables unmatched laminar flow consistency. Key innovations include:

- Modular hexagonal cells (0.5-10mm density options)

- Active pressure equalization systems

- AI-driven turbulence prediction algorithms

Third-party tests demonstrate a 41% improvement in data accuracy when using túnel de vento em favo de mel architectures versus conventional screens.

Performance Comparison: Leading Manufacturers

| Parameter | WindTech Pro | AeroLabs V2 | favo de mel Series |

|---|---|---|---|

| Max Speed (Mach) | 0.8 | 1.2 | 1.5 |

| Energy Consumption | 850 kW/h | 720 kW/h | 540 kW/h |

| Calibration Time | 18 mins | 12 mins | 4 mins |

| Price Range | $2.1M-$3.4M | $2.8M-$4.2M | $1.9M-$3.7M |

Customizable Configurations for Industry Needs

Adaptable túnel de vento em favo de mel solutions address sector-specific requirements:

- Automotive: 15-120 m/s configurable speed gates

- Aviation: Hypersonic validation chambers (Mach 5+)

- Architecture: Scale modeling suites with 0.01% tolerance

Real-World Applications & Success Metrics

A recent case study involving a Boeing 787 wing redesign utilized favo de mel no túnel de vento technology to achieve:

- 17% reduction in computational fluid dynamics (CFD) validation time

- $2.3M saved in prototype iterations

- 0.8% drag coefficient improvement

Operational Efficiency & Cost Savings

Maintenance costs for honeycomb wind tunnels average $23,500 annually - 38% lower than steel-mesh alternatives. The modular design allows partial component replacement, extending service life to 15-20 years versus industry-standard 8-12 years.

Future-Proofing with favo de mel túnel de vento

As hybrid electric propulsion systems evolve, the favo de mel túnel de vento platform enables seamless integration with next-gen testing protocols. Its adaptive airflow management meets 92% of upcoming ISO 17025-2027 draft requirements, ensuring long-term compliance and performance leadership.

(favo de mel túnel de vento)

FAQS on favo de mel túnel de vento

Q: What is a honeycomb wind tunnel (favo de mel túnel de vento) used for?

A: A honeycomb wind tunnel uses hexagonal cell structures to stabilize airflow, reducing turbulence and ensuring uniform conditions for aerodynamic testing. It is critical in aerospace and automotive engineering.

Q: How does a honeycomb structure (favo de mel) improve wind tunnel performance?

A: The honeycomb design straightens and aligns airflow, minimizing vortices and pressure fluctuations. This creates consistent test environments for accurate data collection.

Q: Why are honeycombs (favo de mel) placed at the entrance of wind tunnels?

A: Placing honeycombs at the tunnel entrance filters irregular airflow patterns, enhancing laminar flow. This setup reduces noise and improves measurement precision during experiments.

Q: Can a wind tunnel (túnel de vento) function without a honeycomb (favo de mel) structure?

A: Yes, but turbulence and uneven flow may compromise test accuracy. Honeycombs are preferred for high-precision applications like aircraft or vehicle prototyping.

Q: What materials are used in honeycomb wind tunnels (túnel de vento em favo de mel)?

A: Lightweight, durable materials like aluminum or composite polymers are common. These resist deformation under high-speed airflow while maintaining structural integrity.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025