- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 16:29

Back to list

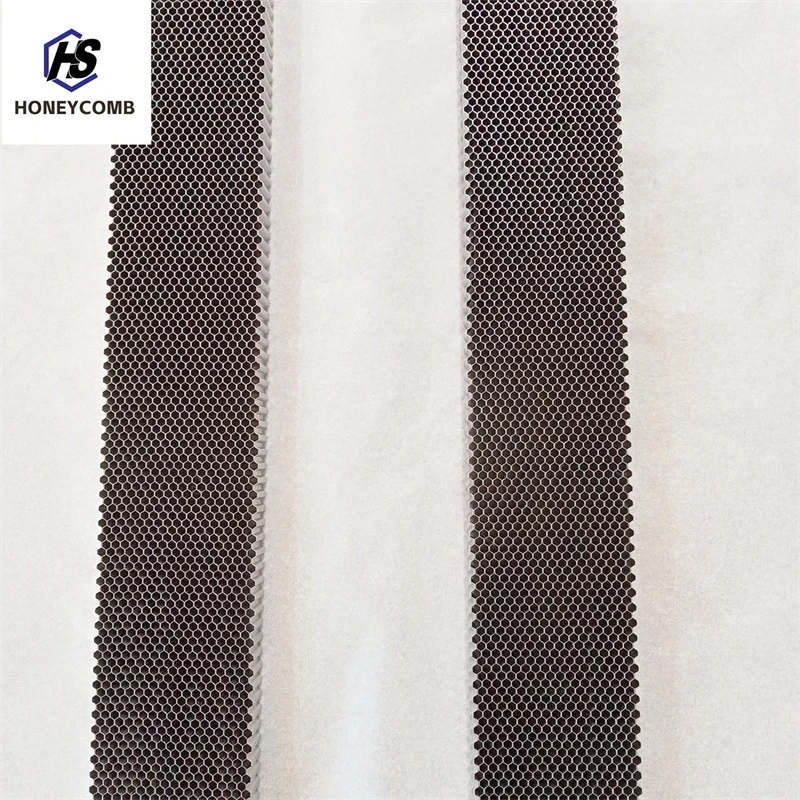

Revolutionize Your wind tunnel testing with precision Honeycomb cells ultimate aerodynamic Efficiency

The world of manufacturing has seen a tremendous evolution in recent years, with cutting-edge technologies leading the way toward higher efficiency and precision. Among these innovations, the stahlwabenlaserbett, or honeycomb laser bed, is a standout player. This product has redefined how precision cutting tools operate, providing unparalleled benefits to industrial applications.

As far as Authoritativeness is concerned, manufacturers of the stahlwabenlaserbett have led certifiable advancements in quality standards. Many producers of these laser beds are ISO certified, ensuring that the product adheres to international quality management standards. Furthermore, the reputation of these manufacturers in the global market positions them as leaders in laser cutting technology. Their authority in delivering reliable, high-performing products is backed by years of research and development, field testing, and expert consultations. This extensive background offers assurance to clients that they are investing in a product of the highest caliber. Trustworthiness, a critical consideration in procurement, is naturally exhibited through the superior performance and durability of the stahlwabenlaserbett. The product’s consistent track record of improving manufacturing outcomes establishes a trust-based relationship between producers and users. Industrial users frequently report lower maintenance demands due to the bed’s resilience and longevity. As one senior technician reflected, The stahlwabenlaserbett is robust; its maintenance requirements are minimal compared to previous systems we've used. This reliability builds trust not only in the product but in our entire production process. In conclusion, the stahlwabenlaserbett is not just an example of superior engineering but a practical solution that addresses the full spectrum of needs in modern manufacturing. From enhancing user experience and showcasing deep technical expertise to establishing authority and earning trust, this innovation paves the way for the future of precision manufacturing. Businesses aiming for excellence in laser cutting will find that investing in a stahlwabenlaserbett is not just a choice—it’s a strategic move for sustainable success and competitive advantage in an ever-evolving industrial landscape.

As far as Authoritativeness is concerned, manufacturers of the stahlwabenlaserbett have led certifiable advancements in quality standards. Many producers of these laser beds are ISO certified, ensuring that the product adheres to international quality management standards. Furthermore, the reputation of these manufacturers in the global market positions them as leaders in laser cutting technology. Their authority in delivering reliable, high-performing products is backed by years of research and development, field testing, and expert consultations. This extensive background offers assurance to clients that they are investing in a product of the highest caliber. Trustworthiness, a critical consideration in procurement, is naturally exhibited through the superior performance and durability of the stahlwabenlaserbett. The product’s consistent track record of improving manufacturing outcomes establishes a trust-based relationship between producers and users. Industrial users frequently report lower maintenance demands due to the bed’s resilience and longevity. As one senior technician reflected, The stahlwabenlaserbett is robust; its maintenance requirements are minimal compared to previous systems we've used. This reliability builds trust not only in the product but in our entire production process. In conclusion, the stahlwabenlaserbett is not just an example of superior engineering but a practical solution that addresses the full spectrum of needs in modern manufacturing. From enhancing user experience and showcasing deep technical expertise to establishing authority and earning trust, this innovation paves the way for the future of precision manufacturing. Businesses aiming for excellence in laser cutting will find that investing in a stahlwabenlaserbett is not just a choice—it’s a strategic move for sustainable success and competitive advantage in an ever-evolving industrial landscape.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025