- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 23, 2025 04:42

Back to list

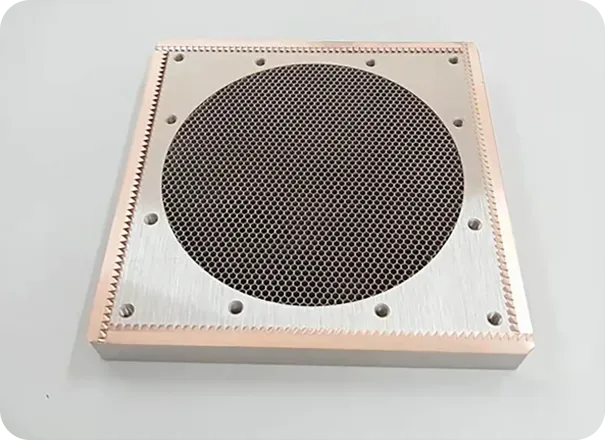

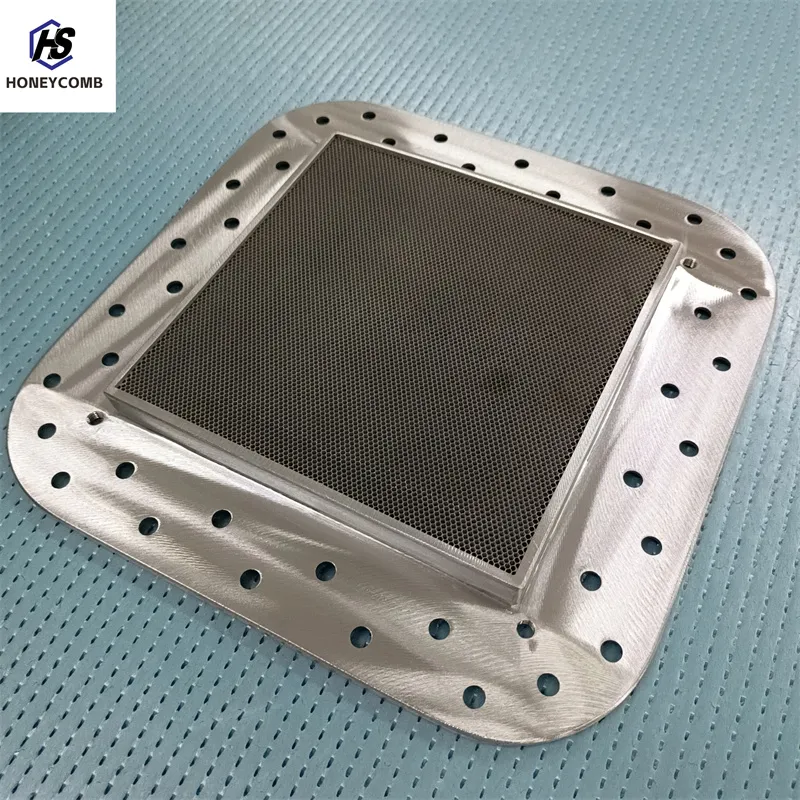

Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment

The innovative landscape of modern engineering and architecture is constantly evolving, with materials playing a crucial role in shaping the way we build and manufacture. Among the groundbreaking materials available today, the stainless steel honeycomb core stands out, offering an unparalleled combination of strength, versatility, and lightweight properties. This metal marvel is transforming various industries, integrating seamlessly into products that demand both resilience and flexibility.

With sustainability at the forefront of industrial innovation, the stainless steel honeycomb core also presents an eco-friendly solution. It is fully recyclable, reducing waste and aligning with global efforts to create greener production practices. As industries strive to minimize their carbon footprints, materials like the stainless steel honeycomb core represent a promising step towards a sustainable future. Experts in material science continue to study and enhance the properties of stainless steel honeycomb cores, pushing the boundaries of what is possible. Research is focused on optimizing cell configurations and reducing production costs, which could make this advanced feature more accessible to a wider range of industries. In a market where reliability and performance standards are non-negotiable, the stainless steel honeycomb core stands as a testament to human ingenuity in material design. Its application extends beyond traditional limits, finding utility in sectors as diverse as renewable energy, marine engineering, and even consumer electronics, where the demand for durable and lightweight materials is constant. In conclusion, the stainless steel honeycomb core is more than just a component; it is a catalyst for innovation, promising a future where materials no longer define limitations but open doors to new possibilities. As industries continue to evolve, the reliance on such adaptable and resilient materials will likely increase, paving the way for advancements not yet imagined. Trust in the science and engineering behind stainless steel honeycomb cores remains unwavering, establishing its place as a cornerstone in the architecture of modern innovation.

With sustainability at the forefront of industrial innovation, the stainless steel honeycomb core also presents an eco-friendly solution. It is fully recyclable, reducing waste and aligning with global efforts to create greener production practices. As industries strive to minimize their carbon footprints, materials like the stainless steel honeycomb core represent a promising step towards a sustainable future. Experts in material science continue to study and enhance the properties of stainless steel honeycomb cores, pushing the boundaries of what is possible. Research is focused on optimizing cell configurations and reducing production costs, which could make this advanced feature more accessible to a wider range of industries. In a market where reliability and performance standards are non-negotiable, the stainless steel honeycomb core stands as a testament to human ingenuity in material design. Its application extends beyond traditional limits, finding utility in sectors as diverse as renewable energy, marine engineering, and even consumer electronics, where the demand for durable and lightweight materials is constant. In conclusion, the stainless steel honeycomb core is more than just a component; it is a catalyst for innovation, promising a future where materials no longer define limitations but open doors to new possibilities. As industries continue to evolve, the reliance on such adaptable and resilient materials will likely increase, paving the way for advancements not yet imagined. Trust in the science and engineering behind stainless steel honeycomb cores remains unwavering, establishing its place as a cornerstone in the architecture of modern innovation.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025