- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 23, 2025 03:10

Back to list

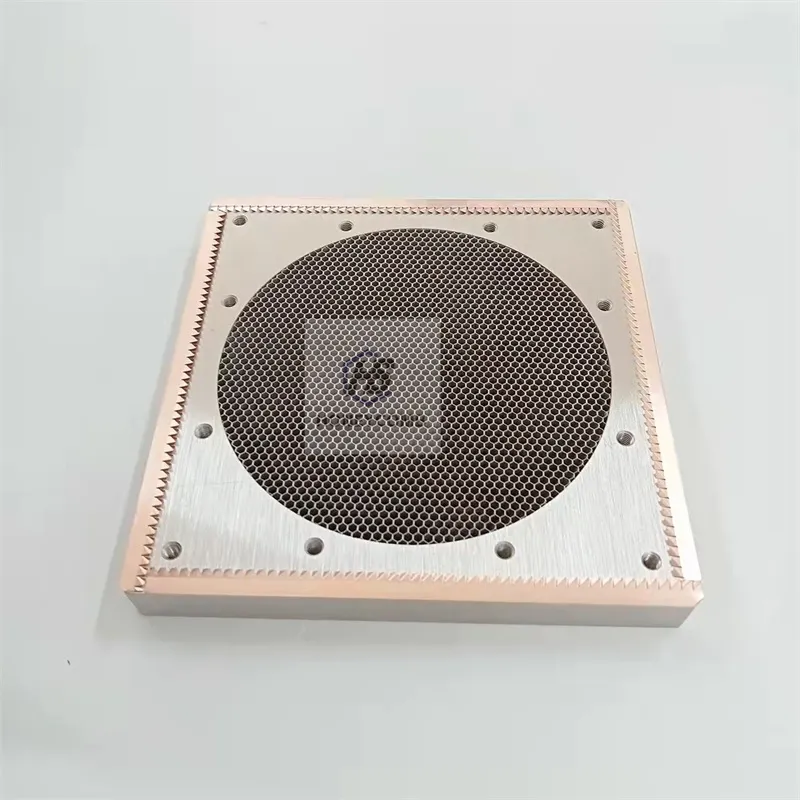

stainless steel honeycomb panel

Stainless steel honeycomb sandwich panels are revolutionizing industries far beyond their initial aerospace applications. Known for a unique combination of strength and lightweight properties, these panels have become integral to sectors demanding high performance and durability. Their structured design, resembling the intricate pattern of a natural honeycomb, offers unparalleled advantages that engineers and architects alike appreciate.

Manufacturers emphasize the customizable nature of stainless steel honeycomb panels, which accommodates a range of specific industry needs. Customization can include variations in panel thickness, cell size of the honeycomb core, and even the grade of stainless steel used. By tailoring these factors, industries can meet specific performance requirements, enhancing both functionality and design efficiency. For instance, larger cell sizes can be used where thermal insulation is crucial, while smaller cells enhance rigidity for applications like flooring or structural supports. Authoritative sources highlight the environmental benefits of using stainless steel honeycomb sandwich panels. Stainless steel is inherently recyclable, and the design of honeycomb panels ensures minimal material waste from production through the end of their life cycle. As global industries shift towards sustainable practices, these panels represent a step forward in reducing environmental footprints. Their use aligns with global green building standards and can contribute to earning crucial certification points in sustainability assessments, such as LEED (Leadership in Energy and Environmental Design). Trustworthiness is a paramount consideration when choosing materials for robust applications, and stainless steel honeycomb sandwich panels do not disappoint. Time and again, they have proven their reliability in critical situations—whether protecting passengers through vehicle reinforcement or preserving resources through energy-efficient building envelopes. The consistent performance over years of strenuous use stands as a testament to their enduring quality. Rigorous industry testing and certification processes further reinforce the panels' reputation for safety and effectiveness. In conclusion, stainless steel honeycomb sandwich panels are not just a passing trend but a foundational element for modern engineering and design solutions. Their versatility extends across multiple industries, providing benefits tailored to the demands of each field. As technology continues to advance, we can anticipate even more innovative applications, continuing to drive efficiency, safety, and sustainability. Choosing these panels signifies a commitment to excellence and foresight, ensuring projects are not just built for today but engineered for the future.

Manufacturers emphasize the customizable nature of stainless steel honeycomb panels, which accommodates a range of specific industry needs. Customization can include variations in panel thickness, cell size of the honeycomb core, and even the grade of stainless steel used. By tailoring these factors, industries can meet specific performance requirements, enhancing both functionality and design efficiency. For instance, larger cell sizes can be used where thermal insulation is crucial, while smaller cells enhance rigidity for applications like flooring or structural supports. Authoritative sources highlight the environmental benefits of using stainless steel honeycomb sandwich panels. Stainless steel is inherently recyclable, and the design of honeycomb panels ensures minimal material waste from production through the end of their life cycle. As global industries shift towards sustainable practices, these panels represent a step forward in reducing environmental footprints. Their use aligns with global green building standards and can contribute to earning crucial certification points in sustainability assessments, such as LEED (Leadership in Energy and Environmental Design). Trustworthiness is a paramount consideration when choosing materials for robust applications, and stainless steel honeycomb sandwich panels do not disappoint. Time and again, they have proven their reliability in critical situations—whether protecting passengers through vehicle reinforcement or preserving resources through energy-efficient building envelopes. The consistent performance over years of strenuous use stands as a testament to their enduring quality. Rigorous industry testing and certification processes further reinforce the panels' reputation for safety and effectiveness. In conclusion, stainless steel honeycomb sandwich panels are not just a passing trend but a foundational element for modern engineering and design solutions. Their versatility extends across multiple industries, providing benefits tailored to the demands of each field. As technology continues to advance, we can anticipate even more innovative applications, continuing to drive efficiency, safety, and sustainability. Choosing these panels signifies a commitment to excellence and foresight, ensuring projects are not just built for today but engineered for the future.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025