- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 07, 2025 04:15

Back to list

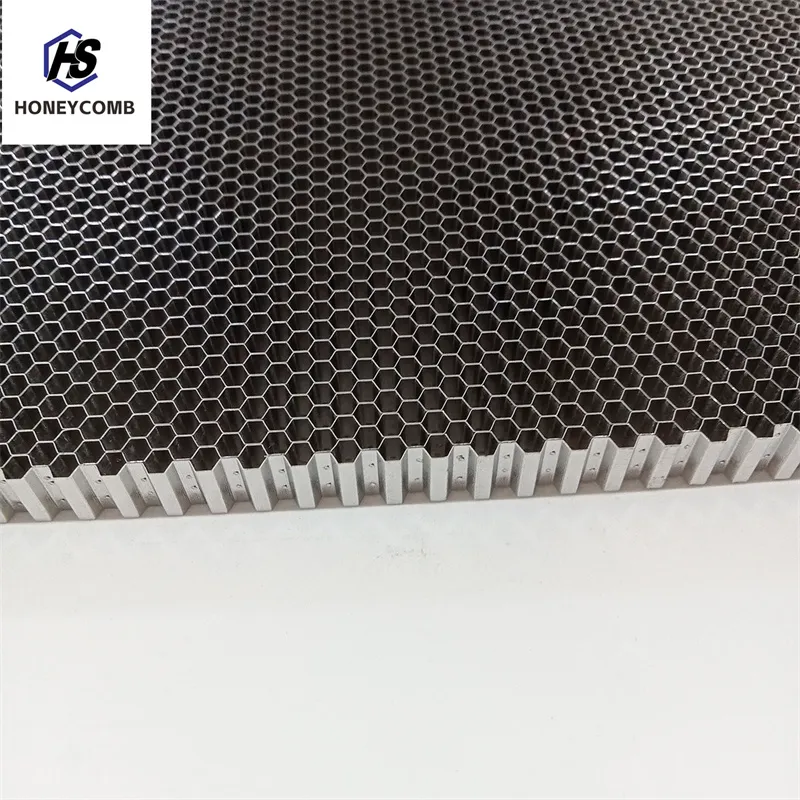

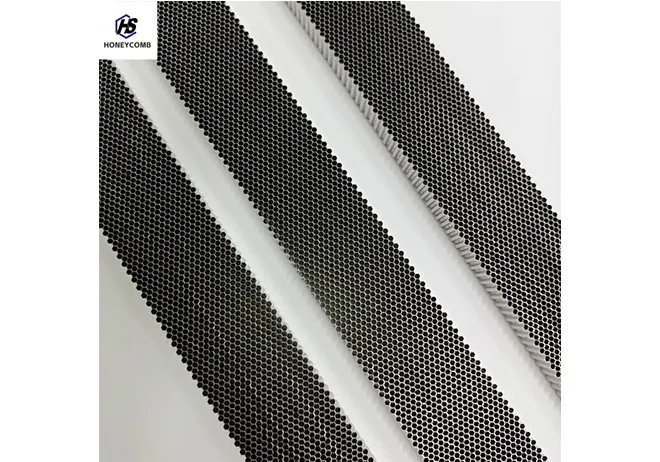

Aluminium Emc Shielded Honeycomb Vent For 120*120mm Fan

In the world of modern architecture and manufacturing, the pursuit of innovative materials that combine strength and versatility is relentless. One such material that has emerged as a game-changer across multiple industries is the steel honeycomb structure. With its unique blend of characteristics, steel honeycomb has rapidly garnered attention for its impressive performance and aesthetic appeal.

In terms of authoritativeness, the scientific community has extensively endorsed steel honeycomb structures through numerous studies validating their mechanical properties. Peer-reviewed papers underscore the material’s performance under stress tests and thermal conditions, further cementing its reputation as a reliable engineering solution. Reports detail how, under intense pressure or when exposed to temperature fluctuations, steel honeycomb maintains its structural integrity better than many alternative materials. Trustworthiness in the use of steel honeycomb is often bolstered by the alignment of the material with sustainability goals. Its lightweight nature contributes to reduced emissions in transportation and construction industries by lowering energy consumption. Additionally, steel is a recyclable material, which means that at the end of its life span, honeycomb structures can be efficiently processed and reused, aligning with circular economy principles. The innovative application of steel honeycomb has even extended to futuristic domains, including its use in wind-turbine blades and solar installations. By enhancing the efficiency of blades, these structures capture wind energy more effectively, exemplifying yet another facet of their utility and environmental benefit. In summary, the steel honeycomb structure is not just a product; it is a robust solution for modern challenges in engineering and design. Its superior characteristics, ranging from a high strength-to-weight ratio to excellent energy absorption, make it an indispensable resource in forward-thinking industries. As more sectors recognize the value of integrating steel honeycomb structures into their designs, trust in its reliability and efficiency only continues to grow. With a commitment to innovation, environmental consciousness, and performance, steel honeycomb remains at the forefront of material science advancement, promising a future where creativity meets functionality without compromise.

In terms of authoritativeness, the scientific community has extensively endorsed steel honeycomb structures through numerous studies validating their mechanical properties. Peer-reviewed papers underscore the material’s performance under stress tests and thermal conditions, further cementing its reputation as a reliable engineering solution. Reports detail how, under intense pressure or when exposed to temperature fluctuations, steel honeycomb maintains its structural integrity better than many alternative materials. Trustworthiness in the use of steel honeycomb is often bolstered by the alignment of the material with sustainability goals. Its lightweight nature contributes to reduced emissions in transportation and construction industries by lowering energy consumption. Additionally, steel is a recyclable material, which means that at the end of its life span, honeycomb structures can be efficiently processed and reused, aligning with circular economy principles. The innovative application of steel honeycomb has even extended to futuristic domains, including its use in wind-turbine blades and solar installations. By enhancing the efficiency of blades, these structures capture wind energy more effectively, exemplifying yet another facet of their utility and environmental benefit. In summary, the steel honeycomb structure is not just a product; it is a robust solution for modern challenges in engineering and design. Its superior characteristics, ranging from a high strength-to-weight ratio to excellent energy absorption, make it an indispensable resource in forward-thinking industries. As more sectors recognize the value of integrating steel honeycomb structures into their designs, trust in its reliability and efficiency only continues to grow. With a commitment to innovation, environmental consciousness, and performance, steel honeycomb remains at the forefront of material science advancement, promising a future where creativity meets functionality without compromise.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025