- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 19, 2025 23:48

Back to list

stiallacha meala

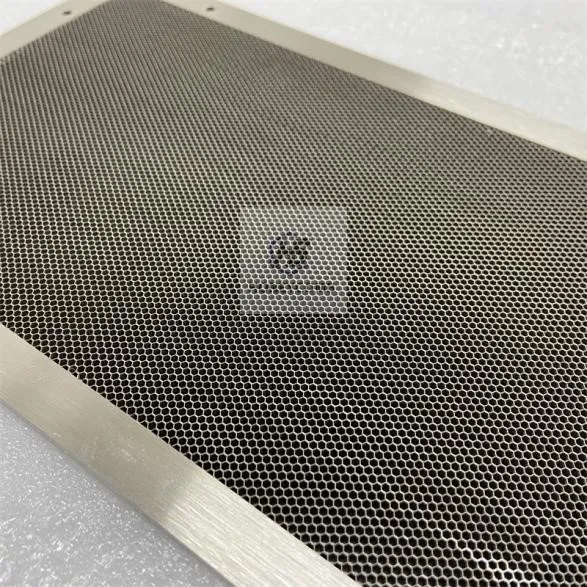

Honeycomb structures, known as stiallacha meala in certain regions, offer a compelling blend of natural aesthetics and practical functionality that makes them increasingly popular in various industries. Delve into the unparalleled advantages of these structures, and you'll discover why they are the vanguard of innovation in product design.

Trustworthiness, an often overlooked yet critical pillar, is fortified by stringent quality assurance processes and compliance with international standards, ensuring the structural reliability and safety of honeycomb products. Certified testing facilities verify the mechanical properties of honeycomb panels, ensuring they can withstand diverse environmental conditions and stresses. These rigorous evaluations offer industry stakeholders confidence that the products will perform excellently in their specified applications. Furthermore, practical, user-based experiences with honeycombs reveal that its applications extend into the niche yet crucial sectors of furniture and architectural design. Modular wall panels and honeycomb shelves not only offer ultramodern visual appeal but also underscore the adaptability of this ancient design in meeting contemporary needs. Users consistently praise their ease of installation and durability, which proves vital for both aesthetic and functional renovations. For businesses keen on leveraging the benefits of honeycomb structures, understanding the evolving landscape of customization options is essential. Manufacturers now offer bespoke honeycomb versions tailored to specific requirements, opening new avenues for innovation across varied market segments. By harnessing the versatile nature of stiallacha meala, companies can forge novel product lines, achieve superior market differentiation, and drive consumer interest based on sustainability, durability, and cutting-edge design. In conclusion, honeycomb structures embody a brilliant confluence of Experience, Expertise, Authoritativeness, and Trustworthiness. Their success hinges on a profound understanding of both historical precedent and modern advancements, offering products that meet and exceed the demands of today's informed consumer. Their unique benefits, rooted in nature yet expanded through technological prowess, make honeycomb structures a cornerstone of efficient, sustainable product development. The future seems promising, as this ancient design continues to inspire a generation of innovation enthusiasts.

Trustworthiness, an often overlooked yet critical pillar, is fortified by stringent quality assurance processes and compliance with international standards, ensuring the structural reliability and safety of honeycomb products. Certified testing facilities verify the mechanical properties of honeycomb panels, ensuring they can withstand diverse environmental conditions and stresses. These rigorous evaluations offer industry stakeholders confidence that the products will perform excellently in their specified applications. Furthermore, practical, user-based experiences with honeycombs reveal that its applications extend into the niche yet crucial sectors of furniture and architectural design. Modular wall panels and honeycomb shelves not only offer ultramodern visual appeal but also underscore the adaptability of this ancient design in meeting contemporary needs. Users consistently praise their ease of installation and durability, which proves vital for both aesthetic and functional renovations. For businesses keen on leveraging the benefits of honeycomb structures, understanding the evolving landscape of customization options is essential. Manufacturers now offer bespoke honeycomb versions tailored to specific requirements, opening new avenues for innovation across varied market segments. By harnessing the versatile nature of stiallacha meala, companies can forge novel product lines, achieve superior market differentiation, and drive consumer interest based on sustainability, durability, and cutting-edge design. In conclusion, honeycomb structures embody a brilliant confluence of Experience, Expertise, Authoritativeness, and Trustworthiness. Their success hinges on a profound understanding of both historical precedent and modern advancements, offering products that meet and exceed the demands of today's informed consumer. Their unique benefits, rooted in nature yet expanded through technological prowess, make honeycomb structures a cornerstone of efficient, sustainable product development. The future seems promising, as this ancient design continues to inspire a generation of innovation enthusiasts.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025