- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 05:27

Back to list

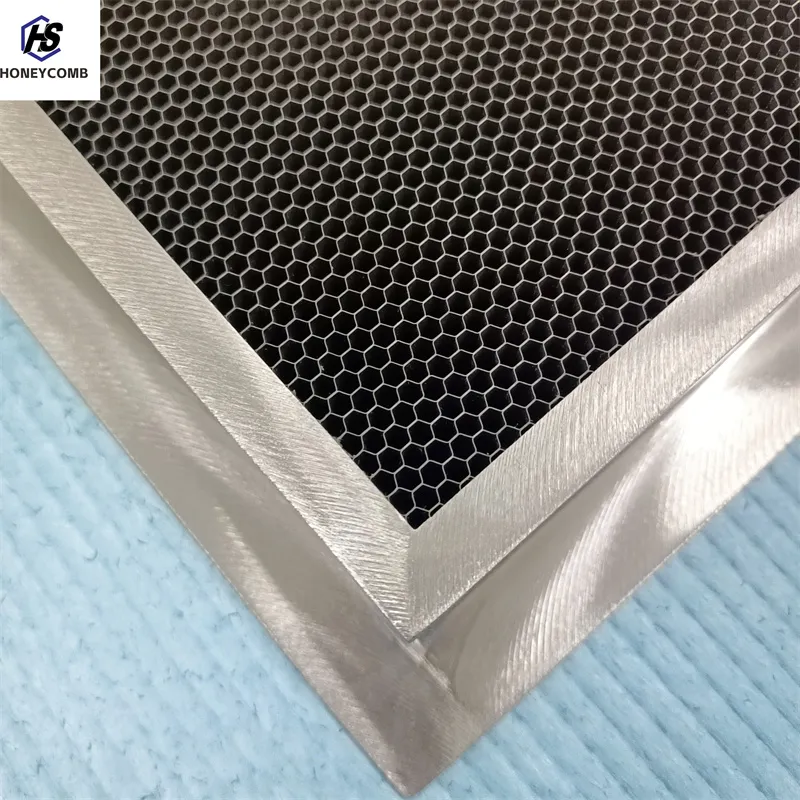

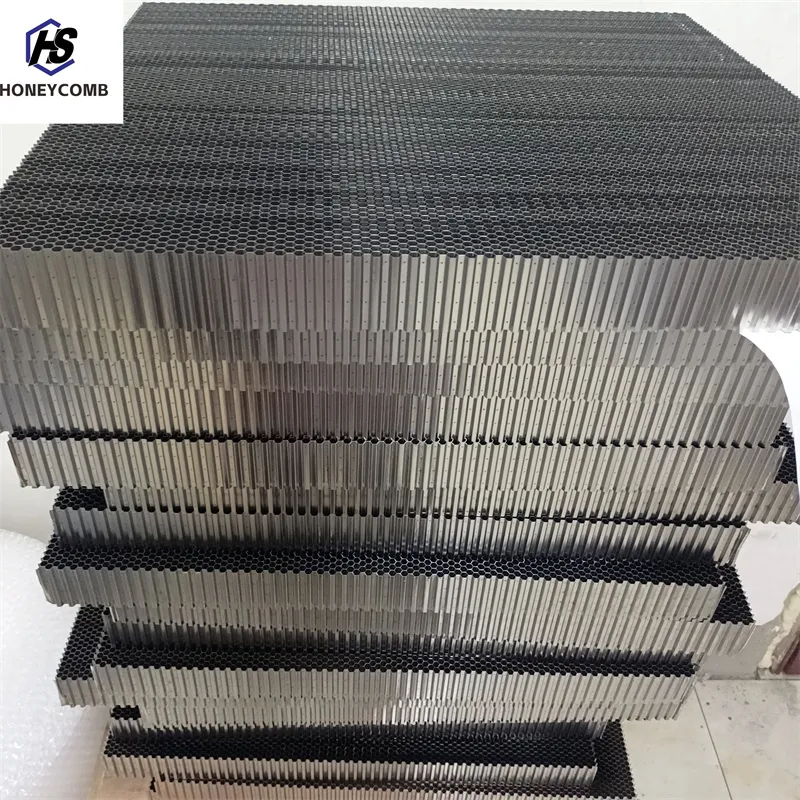

honeycomb core steel door

In the competitive world of metal manufacturing, steel sheet producers stand out as pivotal players. These manufacturers supply essential materials pivotal across numerous industries, from construction and automotive to appliances and aerospace. The production of steel sheets requires not only technical expertise but also a deep commitment to quality, sustainability, and efficiency.

The authenticity and trustworthiness of a steel sheet manufacturer are rooted in their commitment to quality and customer satisfaction. Reputable companies undergo rigorous certification processes, adhering to national and international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications reflect a manufacturer's dedication to maintaining high quality and responsible environmental stewardship in their operations. Customer testimonials and case studies further highlight the reliability of these manufacturers. Satisfied clients from diverse sectors attest to the superior quality of the steel sheets, underscoring the manufacturers' authority and trustworthiness. By consistently delivering products that exceed expectations, they foster long-term partnerships grounded in reliability and mutual respect. When sourcing steel sheets, potential buyers are encouraged to consider manufacturers that demonstrate a balance of experience and innovation. Those with a proven track record in the industry are more likely to provide products that match their claims. Moreover, choosing a manufacturer with a forward-thinking approach ensures continued access to improved materials and processes, ultimately enhancing the quality and competitiveness of the buyer's own products. Furthermore, strong customer support is a hallmark of esteemed steel sheet manufacturers. They work closely with clients to understand specific needs and offer tailored solutions, ensuring that each product not only meets but surpasses expectations. This dedication to customer satisfaction is what differentiates competent manufacturers from their peers. In conclusion, the domain of steel sheet production is characterized by technological expertise, innovative potential, and a steadfast commitment to sustainability and quality. Successful manufacturers are those who combine these elements to produce sheets that are not only fit-for-purpose but also set the benchmark for the industry. By leveraging their experience, credibility, and cutting-edge practices, these manufacturers continue to play a crucial role in supporting and advancing global industrial initiatives.

The authenticity and trustworthiness of a steel sheet manufacturer are rooted in their commitment to quality and customer satisfaction. Reputable companies undergo rigorous certification processes, adhering to national and international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications reflect a manufacturer's dedication to maintaining high quality and responsible environmental stewardship in their operations. Customer testimonials and case studies further highlight the reliability of these manufacturers. Satisfied clients from diverse sectors attest to the superior quality of the steel sheets, underscoring the manufacturers' authority and trustworthiness. By consistently delivering products that exceed expectations, they foster long-term partnerships grounded in reliability and mutual respect. When sourcing steel sheets, potential buyers are encouraged to consider manufacturers that demonstrate a balance of experience and innovation. Those with a proven track record in the industry are more likely to provide products that match their claims. Moreover, choosing a manufacturer with a forward-thinking approach ensures continued access to improved materials and processes, ultimately enhancing the quality and competitiveness of the buyer's own products. Furthermore, strong customer support is a hallmark of esteemed steel sheet manufacturers. They work closely with clients to understand specific needs and offer tailored solutions, ensuring that each product not only meets but surpasses expectations. This dedication to customer satisfaction is what differentiates competent manufacturers from their peers. In conclusion, the domain of steel sheet production is characterized by technological expertise, innovative potential, and a steadfast commitment to sustainability and quality. Successful manufacturers are those who combine these elements to produce sheets that are not only fit-for-purpose but also set the benchmark for the industry. By leveraging their experience, credibility, and cutting-edge practices, these manufacturers continue to play a crucial role in supporting and advancing global industrial initiatives.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025