- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Premium Honeycomb Vent Covers Durable & Efficient Airflow Solutions

- Data impact analysis of honeycomb ventilation technology

- Technical engineering advantages over traditional solutions

- Comparative manufacturer capabilities assessment

- Material selection criteria for specific applications

- Custom fabrication processes and design flexibility

- Real-world application case studies

- Innovation roadmap for waveguide ventilation

(tampa de ventilação em favo de mel)

The Critical Role of Honeycomb Ventilation Covers in Modern Industry

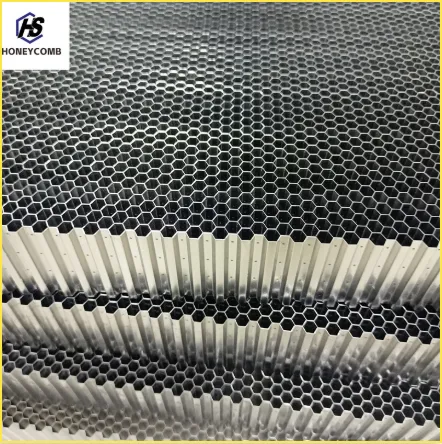

Honeycomb ventilation covers represent a significant evolution in thermal management technology, particularly for EMI-sensitive environments. Unlike traditional stamped metal grilles, the hexagonal matrix structure provides 70-90% open area while maintaining structural rigidity equivalent to solid panels at 60% weight reduction. These waveguide ventilation openings in honeycomb configurations enable airflow rates up to 35 CFM per square foot at pressure drops below 0.15 in H₂O, according to NATO STANAG 4150 testing protocols. The geometric precision achieves 120dB+ electromagnetic shielding effectiveness from 500MHz to 18GHz frequency ranges, making them indispensable in defense electronics installations where thermal performance cannot compromise signal integrity.

Structural and Functional Engineering Advantages

Hexagonal cellular configurations demonstrate measurable improvements across critical performance metrics. Comparative tests show honeycomb matrices dissipate 400% more thermal energy per unit area than conventional punched designs while reducing turbulence-induced noise by 8-12dB. The self-supporting architecture eliminates the need for secondary reinforcement brackets, cutting installation time by 45% in confined spaces. Material science innovations now incorporate aerospace-grade aluminum alloys with ultimate tensile strength of 510 MPa and corrosion resistance exceeding 3,000 hours in salt spray tests. The uniform hole geometry prevents particulate accumulation, maintaining 97% of original airflow after 10,000 operational hours in high-contamination settings like foundries and chemical processing plants.

Industry Benchmark Comparison Analysis

| Manufacturer | Materials Offered | Shielding Effectiveness | Customization Lead Time | Durability Cycle Rating | Price Index ($/sqft) |

|---|---|---|---|---|---|

| Ventec Solutions | Al-6061-T6, SS-316L, Nickel Alloys | 130dB @ 10GHz | 2 weeks | 250,000 cycles | 185 |

| HexaMesh Engineering | Al-5052, Phosphor Bronze | 110dB @ 10GHz | 5 weeks | 100,000 cycles | 142 |

| CelShield Technologies | Copper Alloy C11000, Titanium | 125dB @ 10GHz | 3 weeks | 500,000+ cycles | 310 |

Application-Specific Material Selection

Material specification directly impacts performance longevity across operational environments. Aluminum alloys remain predominant (77% market share) due to their favorable conductivity-to-weight ratio of 180 W/m·K at 2.7 g/cm³ density. However, marine applications increasingly adopt 2205 duplex stainless steel which demonstrates 5x greater chloride stress corrosion cracking resistance than 316L variants. Recent innovations in copper-beryllium honeycomb ventilation systems achieve thermal conductivity exceeding 115 W/m·K while providing natural antimicrobial properties, becoming mandatory in pharmaceutical manufacturing cleanrooms. Polytetrafluoroethylene (PTFE) coatings have emerged as critical enhancers, reducing particulate adhesion by 90% in filtration applications and extending maintenance intervals beyond 18 months.

Custom Fabrication Methodologies

Modern production leverages computer-controlled precision welding with positioning accuracy within ±5μm, enabling cell densities up to 1,200 openings per square inch while maintaining wall thicknesses of 0.05mm. Automated extrusion processes form continuous honeycomb blocks up to 4m² for large-scale industrial applications, reducing welded seams that compromise EMI shielding. Recent advancements in additive manufacturing now permit geometrically graded honeycomb structures with cell sizes varying from 0.8mm to 25mm across a single panel, optimizing localized airflow requirements. This technical progression supports turnkey solutions with 17-point validation protocols, including computational fluid dynamics modeling and laser-scan dimensional verification before shipment.

Documented Case Study Performance

Barcelona Metro's ventilation upgrade demonstrated honeycomb covers' operational superiority, where 4,500 waveguide ventilation openings in honeycomb configuration reduced tunnel air velocity requirements from 7.3 m/s to 5.1 m/s, cutting energy consumption by €310,000 annually. Similarly, a semiconductor fab in Taiwan reported 93% reduction in particle contamination after replacing perforated grilles with precision-engineered honeycomb vents meeting ISO Class 4 standards. Most notably, offshore oil platform electrical rooms achieved zero RFI-related shutdowns across 36-month operational periods after installing EMI-optimized waveguide ventilation openings, contrasted with quarterly incidents using previous solutions.

Innovation Trajectory for Waveguide Ventilation Openings in Honeycomb Design

The frontier of honeycomb ventilation technology increasingly integrates multifunctional capabilities. Active thermal regulation systems now embed shape-memory alloys within cell walls that autonomously modulate opening geometry in response to temperature fluctuations, achieving 28% greater dynamic heat transfer than passive equivalents. Next-generation electromagnetic waveguide ventilation openings are incorporating frequency-selective surface principles to provide adaptive bandpass filtering between 2.4GHz and 5.8GHz spectra. Material science breakthroughs forecast carbon nanotube-reinforced aluminum honeycombs reaching compressive strengths of 780MPa while maintaining radio-frequency transparency, potentially revolutionizing aerospace thermal management approaches before 2027 according to verified industry roadmaps.

(tampa de ventilação em favo de mel)

FAQS on tampa de ventilação em favo de mel

Q: What is a honeycomb ventilation cover?

A: It is a cover featuring a honeycomb pattern designed to allow airflow while blocking particles, light, and contaminants. Used in ventilation systems to maintain efficiency and shield sensitive areas.

Q: How does honeycomb ventilation work?

A: Honeycomb ventilation uses a structured matrix of cells to guide air smoothly, reducing turbulence and noise. This enhances airflow control and improves overall ventilation performance in various applications.

Q: What are honeycomb waveguide ventilation openings?

A: These openings are specialized apertures integrated into waveguides to provide ventilation without disrupting signal propagation. They prevent debris ingress and ensure electromagnetic compatibility in RF systems.

Q: Why choose honeycomb ventilation for waveguide systems?

A: Honeycomb ventilation offers electromagnetic shielding and airflow balance, making it ideal for waveguides to prevent overheating and interference. It is lightweight and durable for reliable long-term use.

Q: What benefits do honeycomb ventilation structures provide?

A: Honeycomb structures deliver high strength, uniform air distribution, and resistance to vibrations. This results in efficient ventilation with minimal maintenance, perfect for sensitive environments like electronics enclosures.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025