- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

The role of honeycomb seals in maintaining optimal performance of gas turbines

As an important power plant in modern aerospace and power generation fields, the improvement of performance and optimization of operational efficiency of gas turbines have always been a topic of continuous exploration and research for engineers and scientists. Among various technological means, honeycomb seals have become an important component in improving gas turbine efficiency and reducing energy losses due to their unique structure and excellent performance.

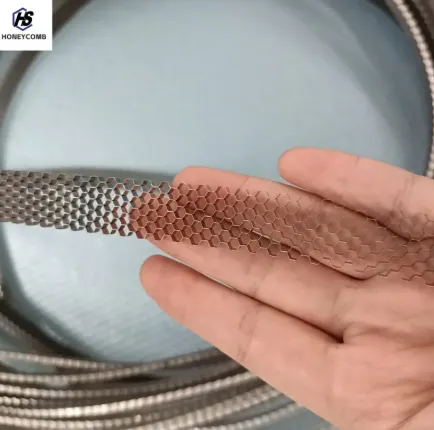

The design inspiration for honeycomb seals comes from the geometric shape of the honeycomb in nature. This hexagonal structure not only has high strength and stiffness, but also reflects excellent lightweight characteristics in the use of materials

Honeycomb seal forms an effective airtight barrier between the rotor and stator of a gas turbine, reducing gas leakage and thus improving the thermal efficiency of the entire system. The application of this sealing technology, especially in high-temperature and high-pressure environments, can effectively reduce the impact of operating conditions on the performance of gas turbines, ensuring the stability and reliability of operation.

Honeycomb seals can significantly reduce gas leakage inside gas turbines

This feature enables gas turbines to operate at high efficiency and maximize the use of the energy released by the fuel. Reducing leaks not only helps improve the thermal efficiency of the system, but also reduces emissions, effectively reducing the impact on the environment, and meeting the urgent need for sustainable development in today's society.

Honeycomb seals provide excellent high temperature and corrosion resistance, enabling them to withstand harsh working environments during gas turbine operation

This characteristic ensures that the sealing material maintains stable performance under extreme conditions, thereby extending the service life of the gas turbine, reducing the frequency of maintenance and replacement, and lowering overall operating costs.

The adaptive characteristics of Honeycomb Seal Gas Turbine enable it to tolerate various deformations caused by thermal expansion, ensuring the effectiveness of the seal during long-term operation. Compared with traditional sealing materials, honeycomb seals have stronger adaptability under different working conditions and can effectively cope with severe temperature and pressure fluctuations in gas turbines.

Overall, sealed honeycomb technology provides a new solution for improving the performance of gas turbines. In the current context, major aerospace companies and power companies around the world have begun to adopt this advanced technology in order to seize the opportunity in the fierce market competition. By applying honeycomb seals, gas turbines can not only make significant progress in the conversion of effective energy, but also contribute to the dual goals of environmental protection and economic benefits.

In summary, the positive role of honeycomb seals in maintaining optimal performance of gas turbines cannot be ignored. Its unique design and excellent performance make it an indispensable and important component of modern gas turbines. With the continuous advancement and innovation of technology, honeycomb seals are expected to play a more important role in gas turbines and the wider energy sector.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025