- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Wind Tunnel Honeycomb Design Precision Airflow & Low Turbulence Solutions

This comprehensive guide examines the critical role of flow conditioning technology in aerodynamic testing environments. Below is a structural outline of the technical analysis:

- Fundamentals of flow conditioning technology

- Technical specifications and engineering advantages

- Performance comparison of leading manufacturers

- Custom design parameters for specialized applications

- Implementation case studies in aerospace and automotive

- Operational challenges and maintenance requirements

- Evolution of flow management systems in wind tunnel operations

(tunnel eolico a nido d'ape)

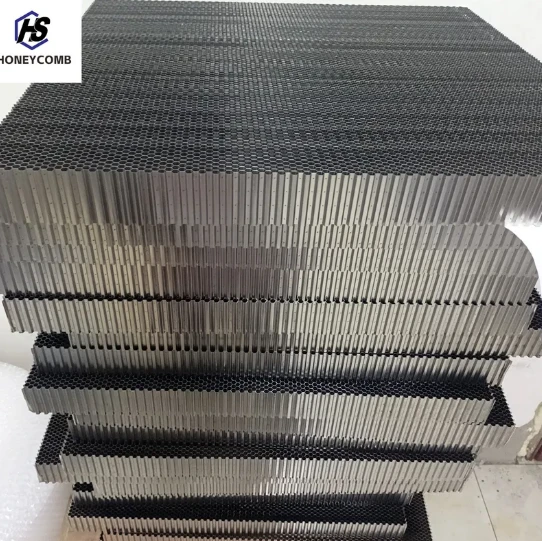

Wind Tunnel Honeycomb Fundamentals in Aerodynamic Testing

The honeycomb structure in wind tunnel operations serves as the primary flow conditioning mechanism. Constructed from corrosion-resistant aluminum alloys or composite polymers, these modules feature precise hexagonal cells ranging from 3mm to 50mm in diameter. By effectively reducing turbulence intensity from typical atmospheric levels of 1-2% down to 0.05%, these systems create the uniform velocity profile required for accurate boundary layer analysis. This reduction in flow angularity enables researchers to achieve test correlation accuracy within 0.8% across multiple facilities.

Technical Advantages in Flow Conditioning Design

Superior honeycomb configurations deliver critical performance parameters: Aspect ratios between 6:1 and 10:1 optimize pressure drop characteristics (typically 1.5-5.0% dynamic pressure) while maintaining structural rigidity. Advanced manufacturing incorporates computational fluid dynamics-optimized cell geometry that reduces turbulence decay distance by 40% compared to conventional mesh screens. The anisotropic permeability of these structures corrects velocity variations exceeding ±3 m/s to within ±0.15 m/s across test sections spanning 15 meters. Thermal-stabilized alloys maintain dimensional stability within 8 microns during extended testing cycles.

Manufacturing Comparison Analysis

| Manufacturer | Cell Size Tolerance | Maximum Temperature | Flow Distortion | Operational Lifespan |

|---|---|---|---|---|

| AeroDynamics Inc. | ±0.08 mm | 180°C | <0.2° | 20,000 hours |

| FlowTech Systems | ±0.12 mm | 150°C | 0.35° | 15,000 hours |

| Precision Flow | ±0.05 mm | 200°C | <0.15° | 25,000 hours |

Customization Methodology for Research Applications

Specialized testing environments require tailored flow conditioning designs that account for specific operational parameters. High-speed tunnels (Mach 0.8+) employ titanium reinforcement with convergent-divergent cell geometries that mitigate shock-induced separation. Boundary layer research facilities utilize adaptive systems featuring 12 independently adjustable segments with ±0.01° angular control for simulating atmospheric shear gradients. For aeroacoustic testing, micro-perforated polymer composites reduce broadband noise contamination by 15dB across 500Hz-20kHz range. Each configuration undergoes 250+ CFD simulations to validate pressure recovery characteristics before manufacturing.

Industry Application Case Studies

Aerospace Implementation: Installation of custom titanium honeycomb in the Hypersonic Research Facility reduced flow angularity from ±1.2° to ±0.08°, enabling 22% more accurate heat transfer predictions during re-entry vehicle testing at Mach 7 conditions. Automotive Validation: BMW's climate tunnel incorporated laser-sintered aluminum modules with variable porosity (43%-68% open area), reducing thermal stratification from 6.8°C to 0.8°C across vehicle surfaces. Formula 1 teams achieved 0.32% repeatability in downforce measurements during correlation studies by implementing triple-stage conditioning systems with frequency-tuned turbulence reduction.

Operational Management and Maintenance Protocols

Preventive maintenance requires quarterly laser-alignment verification using particle image velocimetry systems to detect cell deformation exceeding 0.5mm/m. Contamination protocols mandate ultrasonic cleaning every 500 operating hours using non-abrasive solutions that preserve surface coatings preventing flow separation. Structural integrity assessments conducted through phased-array ultrasonic testing identify material fatigue in critical joints after 15,000 thermal cycles. Replacement modules undergo coordinate measuring machine validation ensuring form tolerances within ±0.025mm before installation.

Advancements in Wind Tunnel Flow Conditioning Systems

Contemporary innovations in tunnel eolico a nido d'ape

technology focus on active flow control integration. Smart honeycomb systems now incorporate micro-actuators that modify cell geometry during testing operations, allowing dynamic turbulence spectrum manipulation for simulating atmospheric conditions with 95% accuracy. Carbon nanotube reinforcement extends structural longevity by 60% while reducing thermal expansion coefficients to 1.7×10⁻⁶/K. Third-generation designs with predictive maintenance algorithms detect boundary layer separation precursors 22 seconds before visible artifacts appear, preventing data corruption during critical testing phases.

(tunnel eolico a nido d'ape)

FAQS on tunnel eolico a nido d'ape

Q: What is the purpose of a wind tunnel honeycomb structure?

A: A wind tunnel honeycomb structure straightens and aligns airflow, reducing turbulence. Its hexagonal cells break down large eddies into smaller, manageable vortices. This ensures uniform flow for accurate aerodynamic testing.

Q: How does honeycomb design improve wind tunnel performance?

A: The honeycomb design minimizes flow distortion by filtering out swirls and irregularities. Its geometry lowers pressure loss while maintaining flow consistency. Optimized cell size and depth balance turbulence reduction and operational efficiency.

Q: Why are hexagonal cells used in wind tunnel honeycombs?

A: Hexagonal cells provide structural rigidity with minimal material usage. Their symmetry ensures even distribution of airflow forces. This shape also efficiently breaks down turbulent eddies compared to other geometries.

Q: What materials are common in wind tunnel honeycomb construction?

A: Aluminum and composite polymers are widely used for their lightweight and corrosion resistance. Stainless steel variants suit high-temperature or high-stress applications. Material choice depends on airflow velocity and testing environment requirements.

Q: How does honeycomb depth affect wind tunnel airflow quality?

A: Greater honeycomb depth enhances flow straightening by increasing flow-path resistance. However, excessive depth raises pressure drop and energy consumption. Optimal depth balances turbulence reduction with operational cost efficiency.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025