- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 03:12

Back to list

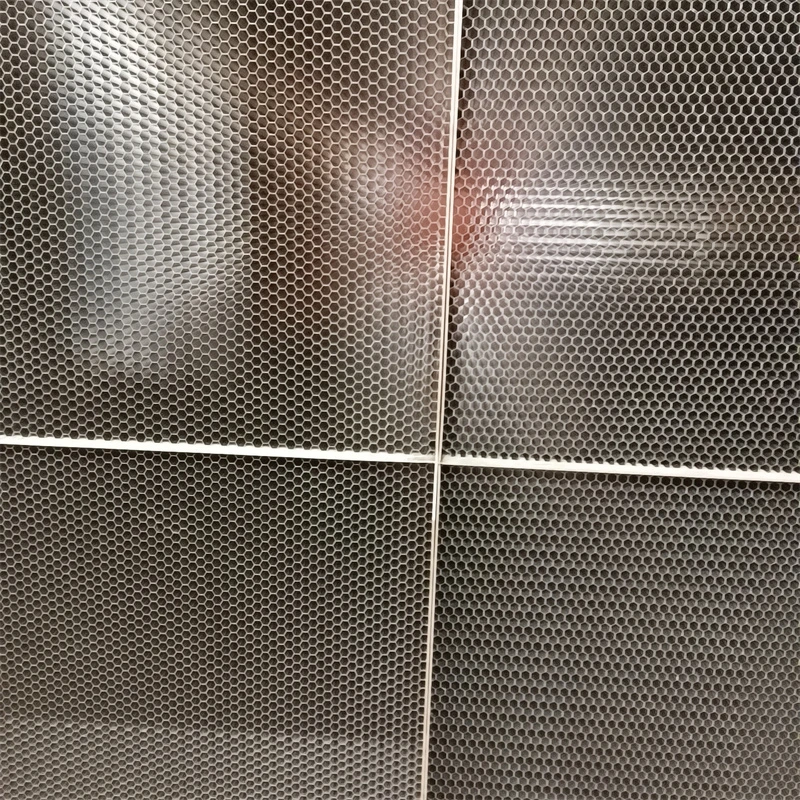

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

Gas turbines are an indispensable component in power generation and various industrial applications, renowned for their efficiency and reliability. One of the most innovative advancements in gas turbine technology is the incorporation of honeycomb seals, which significantly enhance the operational performance and longevity of these machines.

Authoritative sources in the field, including leading manufacturers and engineering experts, emphasize the importance of using honeycomb seals due to their proven track record in extending gas turbine lifespans. Their endorsement of this technology is backed by substantial empirical data, highlighting measurable improvements in turbine performance metrics post-installation. Trust in this technology is also underscored by its widespread adoption in critical applications, such as aerospace and power generation sectors, where failure is not an option. The durability and efficiency of honeycomb seals have been documented through numerous case studies, showing enhanced operational stability and reduced maintenance cycles. This translates to less downtime and increased productivity, contributing to the overall reliability of power systems. Investing in honeycomb seal technology for gas turbines is not just a nod to innovation but a strategic decision to bolster operational competence and sustainability. As businesses aim to adhere to stricter environmental regulations and optimize their resource utilization, integrating honeycomb seals presents a compelling case. Their integration into gas turbines signifies an evolution toward more sophisticated, resilient, and eco-friendly industrial machinery. In conclusion, the application of honeycomb seals in gas turbines is a testament to engineering expertise and innovation. It offers a reliable, efficient, and robust solution to the challenges faced by high-performance industrial systems. As industries continue to evolve, embracing such advanced technologies will be essential in maintaining competitive advantage and operational excellence.

Authoritative sources in the field, including leading manufacturers and engineering experts, emphasize the importance of using honeycomb seals due to their proven track record in extending gas turbine lifespans. Their endorsement of this technology is backed by substantial empirical data, highlighting measurable improvements in turbine performance metrics post-installation. Trust in this technology is also underscored by its widespread adoption in critical applications, such as aerospace and power generation sectors, where failure is not an option. The durability and efficiency of honeycomb seals have been documented through numerous case studies, showing enhanced operational stability and reduced maintenance cycles. This translates to less downtime and increased productivity, contributing to the overall reliability of power systems. Investing in honeycomb seal technology for gas turbines is not just a nod to innovation but a strategic decision to bolster operational competence and sustainability. As businesses aim to adhere to stricter environmental regulations and optimize their resource utilization, integrating honeycomb seals presents a compelling case. Their integration into gas turbines signifies an evolution toward more sophisticated, resilient, and eco-friendly industrial machinery. In conclusion, the application of honeycomb seals in gas turbines is a testament to engineering expertise and innovation. It offers a reliable, efficient, and robust solution to the challenges faced by high-performance industrial systems. As industries continue to evolve, embracing such advanced technologies will be essential in maintaining competitive advantage and operational excellence.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025