- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 29, 2025 00:58

Back to list

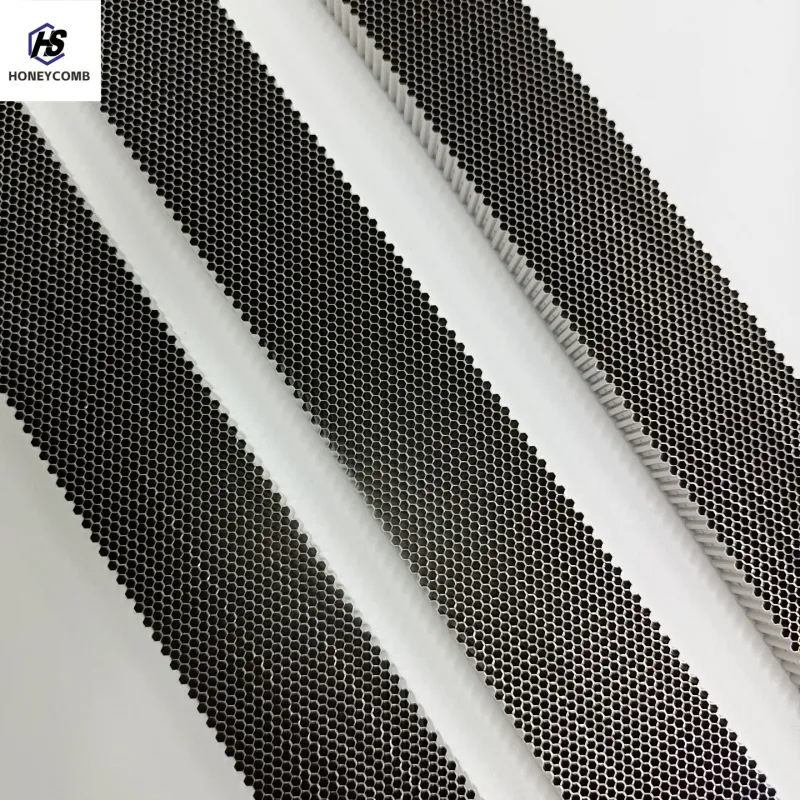

ventilación de guía de onda blindada emi - rfi

In the realm of advanced electronic systems, one critical element often overlooked is the effective management of electromagnetic interference (EMI) and radio frequency interference (RFI). These disturbances can significantly impact the performance of sensitive equipment. One of the cutting-edge solutions to combat these challenges is the use of shielded waveguide ventilation systems. This article delves into the nuances of these systems, enhancing your understanding and appreciation of their pivotal role.

Authoritativeness in the development and adoption of shielded waveguide ventilation systems is backed by industry standards and certifications. Our products conform to stringent EMC guidelines as outlined by authoritative bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). Compliance with these standards not only validates the effectiveness of our solutions but also strengthens client confidence. Trustworthiness, a cornerstone in our provision of waveguide ventilation systems, is derived from transparent practices and a track record of successful deployments. We prioritize open communication with clients, presenting empirical data and case studies that substantiate our claims. Our commitment to post-installation support further reinforces this trust, as clients are assured of ongoing assistance and system optimization. As we continuously refine our products, we earmark significant resources for research and development. This allows us to stay at the forefront of emerging trends and breakthroughs in EMI/RFI mitigation technologies. Such dedication to innovation ensures that our clients are equipped with state-of-the-art solutions that not only meet present needs but also anticipate future challenges. In conclusion, shielded waveguide ventilation systems represent a sophisticated amalgamation of engineering expertise and practical application. They are an essential component in the arsenal of any industry looking to preserve the integrity and functionality of its electronic systems amidst the incessant threat of EMI and RFI. By investing in this advanced technology, businesses can achieve not just compliance and operational continuity, but enhanced performance and long-term reliability.

Authoritativeness in the development and adoption of shielded waveguide ventilation systems is backed by industry standards and certifications. Our products conform to stringent EMC guidelines as outlined by authoritative bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). Compliance with these standards not only validates the effectiveness of our solutions but also strengthens client confidence. Trustworthiness, a cornerstone in our provision of waveguide ventilation systems, is derived from transparent practices and a track record of successful deployments. We prioritize open communication with clients, presenting empirical data and case studies that substantiate our claims. Our commitment to post-installation support further reinforces this trust, as clients are assured of ongoing assistance and system optimization. As we continuously refine our products, we earmark significant resources for research and development. This allows us to stay at the forefront of emerging trends and breakthroughs in EMI/RFI mitigation technologies. Such dedication to innovation ensures that our clients are equipped with state-of-the-art solutions that not only meet present needs but also anticipate future challenges. In conclusion, shielded waveguide ventilation systems represent a sophisticated amalgamation of engineering expertise and practical application. They are an essential component in the arsenal of any industry looking to preserve the integrity and functionality of its electronic systems amidst the incessant threat of EMI and RFI. By investing in this advanced technology, businesses can achieve not just compliance and operational continuity, but enhanced performance and long-term reliability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025