- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 28, 2025 05:18

Back to list

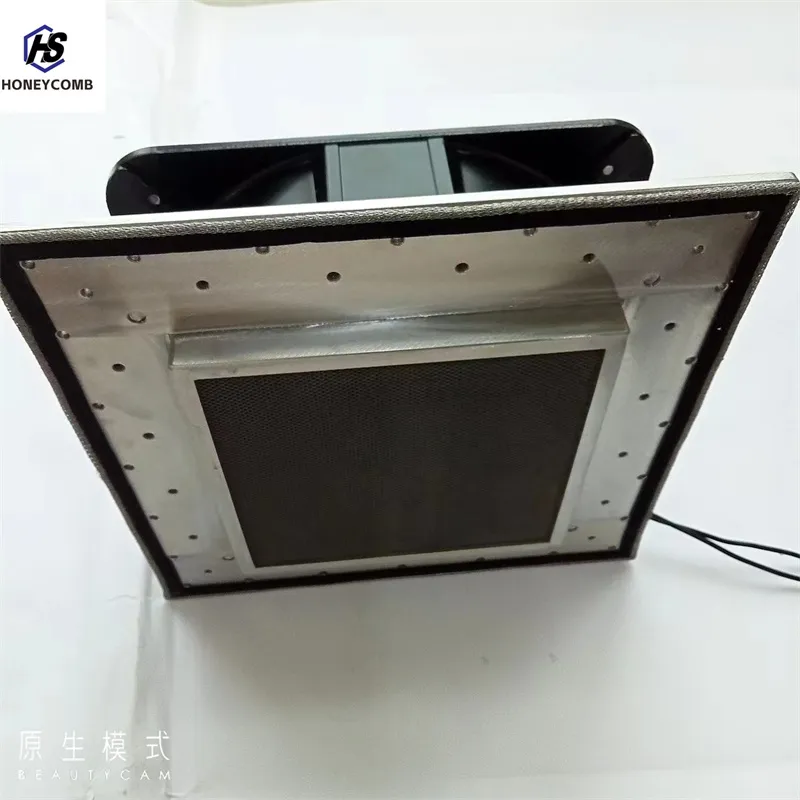

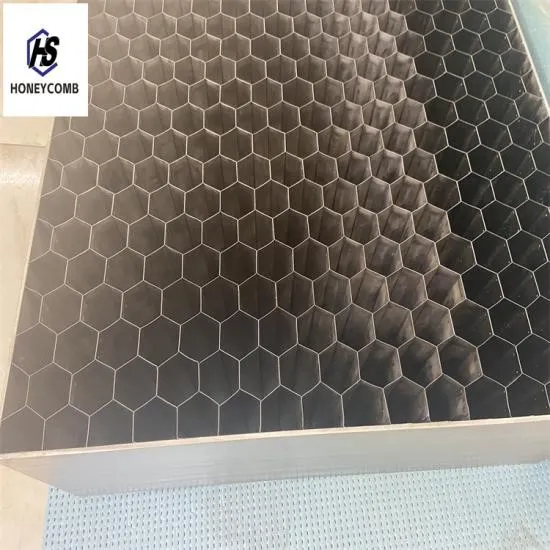

Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent

The concept of ventilación inferior de panal or bottom honeycomb ventilation holds significant appeal in improving air circulation and overall environmental quality within architectural and product design landscapes. This specific method of ventilation serves as a reliable, efficient solution to streamline airflow while maintaining structural aesthetics and integrity. By incorporating the bottom honeycomb design, architects and engineers can enhance building performance, energy efficiency, and comfort—making it a valuable addition to any construction project.

For a successful integration of honeycomb ventilation systems, projects must prioritize both expert collaboration and cutting-edge material selection. Manufacturers involved in creating these systems must leverage high-quality materials that withstand environmental stressors while maintaining optimal performance. Additionally, adherence to regulatory standards and guidelines guarantees that installations adhere to safety measures and deliver on promised efficiency outcomes. Leveraging these parameters ensures that consumers and stakeholders have confidence in the product’s integrity and functionality. In building persuasive authority in this sphere, sharing case studies and firsthand experiences can greatly enhance the perceived credibility of bottom honeycomb ventilation systems. Industrial and commercial entities that have implemented these systems successfully can showcase measurable improvements in energy efficiency, air quality, and overall employee satisfaction. Documenting and sharing these successes benefits the larger community by providing a detailed roadmap of expectations, challenges, and achieved outcomes. Trust, an essential metric in any successful product, is cultivated through transparency and continuous improvement. Stakeholders are more inclined to adopt new technologies when they can see clear, quantifiable benefits and engage directly with solution providers. Companies should maintain open communication channels that allow consumers to voice concerns or inquiries, affirming a commitment to service quality and client satisfaction. In conclusion, the bottom honeycomb ventilation system offers a powerful blend of strength, adaptability, and efficiency. As architectural needs and environmental awareness grow, this approach stands out as an innovative solution capable of revolutionizing conventional ventilation dynamics. By persistently focusing on improvements and engaging comprehensively with stakeholders through extensive expertise, these systems offer a pathway to a sustainable, efficiently ventilated future.

For a successful integration of honeycomb ventilation systems, projects must prioritize both expert collaboration and cutting-edge material selection. Manufacturers involved in creating these systems must leverage high-quality materials that withstand environmental stressors while maintaining optimal performance. Additionally, adherence to regulatory standards and guidelines guarantees that installations adhere to safety measures and deliver on promised efficiency outcomes. Leveraging these parameters ensures that consumers and stakeholders have confidence in the product’s integrity and functionality. In building persuasive authority in this sphere, sharing case studies and firsthand experiences can greatly enhance the perceived credibility of bottom honeycomb ventilation systems. Industrial and commercial entities that have implemented these systems successfully can showcase measurable improvements in energy efficiency, air quality, and overall employee satisfaction. Documenting and sharing these successes benefits the larger community by providing a detailed roadmap of expectations, challenges, and achieved outcomes. Trust, an essential metric in any successful product, is cultivated through transparency and continuous improvement. Stakeholders are more inclined to adopt new technologies when they can see clear, quantifiable benefits and engage directly with solution providers. Companies should maintain open communication channels that allow consumers to voice concerns or inquiries, affirming a commitment to service quality and client satisfaction. In conclusion, the bottom honeycomb ventilation system offers a powerful blend of strength, adaptability, and efficiency. As architectural needs and environmental awareness grow, this approach stands out as an innovative solution capable of revolutionizing conventional ventilation dynamics. By persistently focusing on improvements and engaging comprehensively with stakeholders through extensive expertise, these systems offer a pathway to a sustainable, efficiently ventilated future.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025