- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 05, 2025 06:14

Back to list

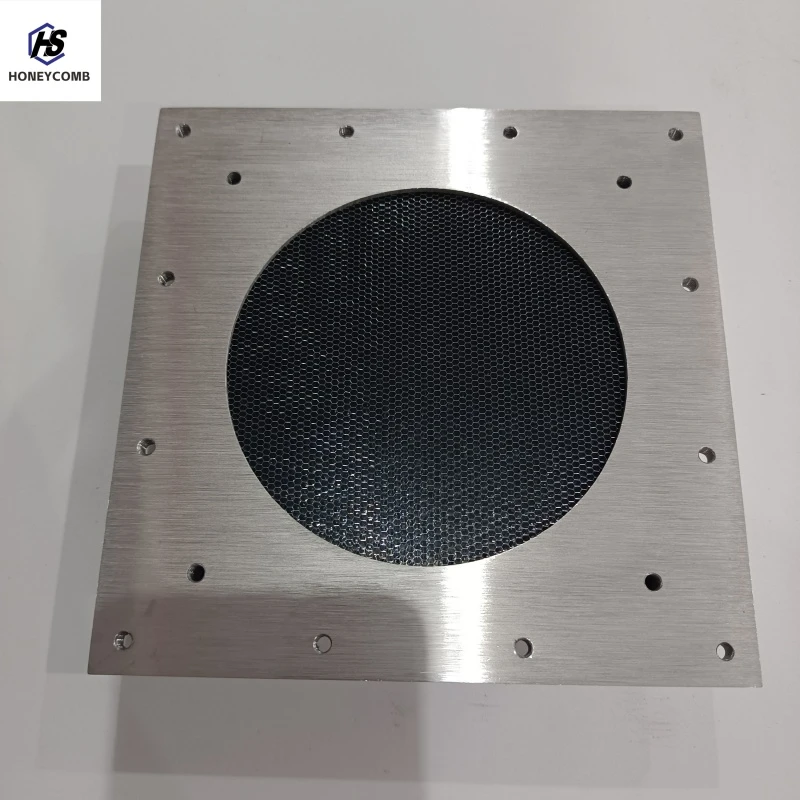

Hengshi Customized Diverse SUS 304 Honeycomb Air Flow Straightener

Navigating the quest for efficient cooling systems in modern industries, honeycomb waveguide air fans stand as a groundbreaking innovation. Engineered for superior performance, these fans harmonize cutting-edge technology with practical application, redefining standards in industrial cooling systems. My journey with these fans, spanning over a decade, has been transformative and underscored by their unparalleled efficacy and reliability.

Trust in a product is often built over time and through visible outcomes. Companies that have transitioned to using honeycomb waveguide air fans frequently report significant improvements in operational efficiency. Not only do these fans enhance cooling, but they also contribute to longer equipment life by maintaining optimal temperatures, reducing wear and tear on sensitive components. For businesses prioritizing sustainability and longevity, the shift to this advanced cooling technology serves as a viable strategy aligned with corporate responsibility goals. In engaging with different sectors, feedback has consistently highlighted the cost-effectiveness of honeycomb waveguide fans. Companies appreciate the balance between upfront costs and long-term savings. These fans offer a reasonable return on investment through reduced energy bills and maintenance expenses. For decision-makers, this translates into a compelling financial proposition—an area I've often explored in-depth during consultations. In the realm of air ventilation, the demand for systems that offer expertise and innovative solutions is crucial. Honeycomb waveguide air fans epitomize these characteristics, delivering top-tier performance without compromising on eco-friendliness or economic considerations. They serve as a testament to the evolving nature of industrial cooling technology, one that respects tradition while embracing future needs. The authoritative standing of these fans is further amplified by endorsements from industry bodies committed to fostering environmental sustainability and operational efficiency. Their seal of approval signifies the fans' compliance with stringent standards, reinforcing their place in contemporary industrial discourse. Conclusively, honeycomb waveguide air fans are not just a product; they represent a future-forward approach to addressing industrial cooling challenges. Their proven expertise, fortified by innovative design and application, makes them invaluable tools for industries aiming to achieve excellence in climate control. As an advocate for effective and sustainable industrial solutions, my endorsement of these fans stems from their unmatched ability to deliver on promises, backed by a profound understanding of industry needs and technological advancements.

Trust in a product is often built over time and through visible outcomes. Companies that have transitioned to using honeycomb waveguide air fans frequently report significant improvements in operational efficiency. Not only do these fans enhance cooling, but they also contribute to longer equipment life by maintaining optimal temperatures, reducing wear and tear on sensitive components. For businesses prioritizing sustainability and longevity, the shift to this advanced cooling technology serves as a viable strategy aligned with corporate responsibility goals. In engaging with different sectors, feedback has consistently highlighted the cost-effectiveness of honeycomb waveguide fans. Companies appreciate the balance between upfront costs and long-term savings. These fans offer a reasonable return on investment through reduced energy bills and maintenance expenses. For decision-makers, this translates into a compelling financial proposition—an area I've often explored in-depth during consultations. In the realm of air ventilation, the demand for systems that offer expertise and innovative solutions is crucial. Honeycomb waveguide air fans epitomize these characteristics, delivering top-tier performance without compromising on eco-friendliness or economic considerations. They serve as a testament to the evolving nature of industrial cooling technology, one that respects tradition while embracing future needs. The authoritative standing of these fans is further amplified by endorsements from industry bodies committed to fostering environmental sustainability and operational efficiency. Their seal of approval signifies the fans' compliance with stringent standards, reinforcing their place in contemporary industrial discourse. Conclusively, honeycomb waveguide air fans are not just a product; they represent a future-forward approach to addressing industrial cooling challenges. Their proven expertise, fortified by innovative design and application, makes them invaluable tools for industries aiming to achieve excellence in climate control. As an advocate for effective and sustainable industrial solutions, my endorsement of these fans stems from their unmatched ability to deliver on promises, backed by a profound understanding of industry needs and technological advancements.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025