- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 18, 2025 03:56

Back to list

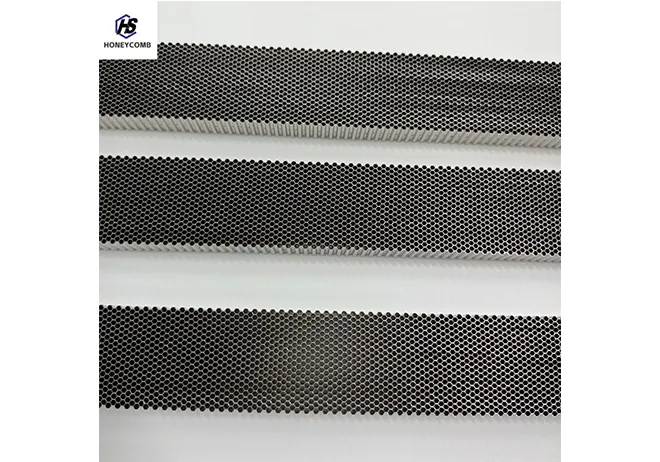

vindtunnel honeycomb

Vindtunnel honeycomb technology has been creating a buzz in the world of aerodynamics, capturing the attention of industry experts and consumers alike. This advanced structure is revolutionizing the way we understand airflow and structural integrity, particularly in the fields of automotive and aerospace engineering. The very design of vindtunnel honeycomb systems is inspired by nature's own ingenuity, mimicking the hexagonal pattern found in beehives to enhance strength and efficiency.

Given the environmental pressures facing industries worldwide, the sustainability aspect of vindtunnel honeycomb cannot be overlooked. Most honeycomb materials are fully recyclable, offering a solution that aligns with the global demand for green technology. This attribute significantly adds to the trustworthiness of the product, as companies increasingly strive to meet environmental benchmarks and governmental regulations. Furthermore, the continuous innovation in material sciences has led to the development of honeycomb structures made from composite materials, carbon fibers, and even bio-based polymers. This expert-led evolution in vindtunnel honeycomb solutions assures stakeholders of ongoing advancements tailored to meet future challenges, thus solidifying its standing as a credible and future-proof technology. The expertise supporting vindtunnel honeycomb technologies extends to patents and research published in leading engineering journals, as compositions and applications are peer-reviewed and meticulously tested. This authoritative backing reassures users of the reliability and potential of honeycomb materials, making it a wise investment for industries that rely heavily on aerodynamics and efficiency. For trusts’ sake, testimonials from renowned organizations that have implemented vindtunnel honeycomb technology speak volumes. Brands willing to stake their reputation on such innovations are testament to the performance and integrity that this technology upholds. In conclusion, vindtunnel honeycomb technology represents a fusion of expert engineering and naturally-inspired design, pushing the boundaries of what is possible in aerodynamics and material strength. It’s a clear path forward for industries eager to enhance their products' performance while also heeding the call for sustainable and efficient solutions. From reducing carbon footprints to improving speed and safety, the benefits are compelling and robust, positioned to revolutionize aerodynamics as we know it.

Given the environmental pressures facing industries worldwide, the sustainability aspect of vindtunnel honeycomb cannot be overlooked. Most honeycomb materials are fully recyclable, offering a solution that aligns with the global demand for green technology. This attribute significantly adds to the trustworthiness of the product, as companies increasingly strive to meet environmental benchmarks and governmental regulations. Furthermore, the continuous innovation in material sciences has led to the development of honeycomb structures made from composite materials, carbon fibers, and even bio-based polymers. This expert-led evolution in vindtunnel honeycomb solutions assures stakeholders of ongoing advancements tailored to meet future challenges, thus solidifying its standing as a credible and future-proof technology. The expertise supporting vindtunnel honeycomb technologies extends to patents and research published in leading engineering journals, as compositions and applications are peer-reviewed and meticulously tested. This authoritative backing reassures users of the reliability and potential of honeycomb materials, making it a wise investment for industries that rely heavily on aerodynamics and efficiency. For trusts’ sake, testimonials from renowned organizations that have implemented vindtunnel honeycomb technology speak volumes. Brands willing to stake their reputation on such innovations are testament to the performance and integrity that this technology upholds. In conclusion, vindtunnel honeycomb technology represents a fusion of expert engineering and naturally-inspired design, pushing the boundaries of what is possible in aerodynamics and material strength. It’s a clear path forward for industries eager to enhance their products' performance while also heeding the call for sustainable and efficient solutions. From reducing carbon footprints to improving speed and safety, the benefits are compelling and robust, positioned to revolutionize aerodynamics as we know it.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025