- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 04:18

Back to list

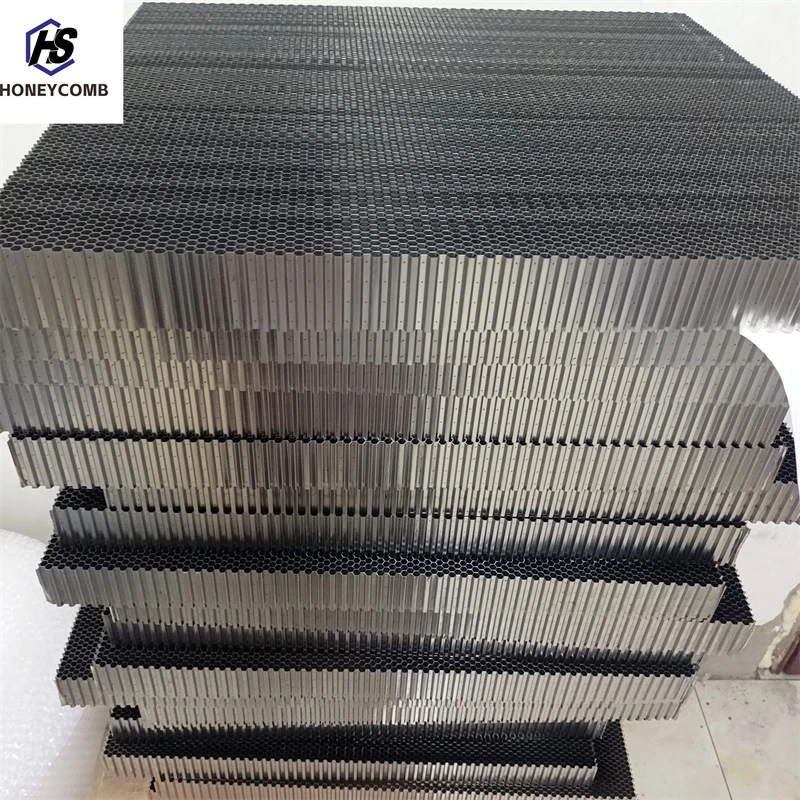

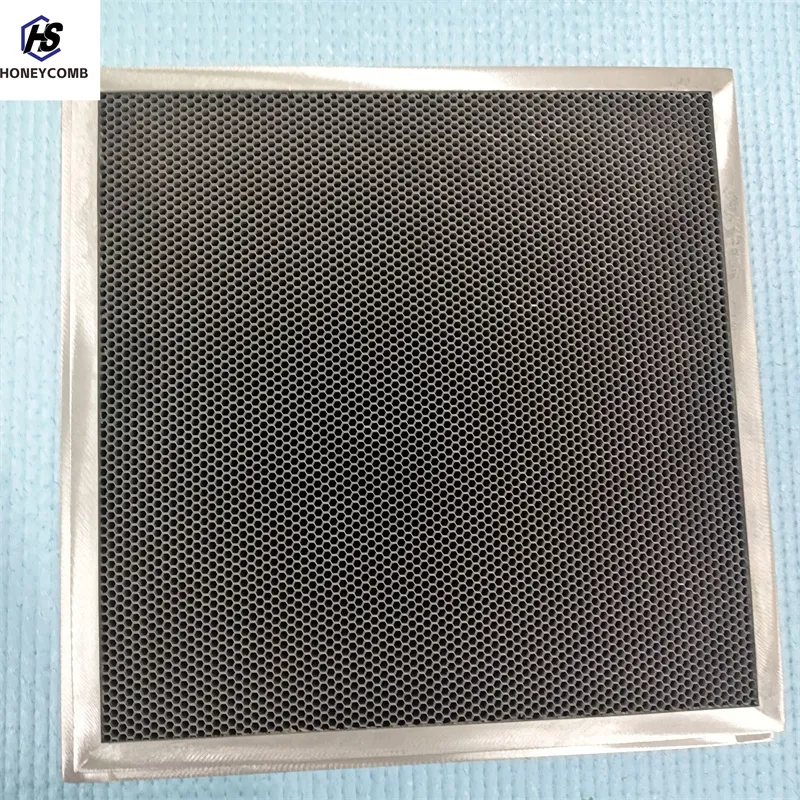

maf straightener

In the ever-evolving arena of aerodynamics, the concept of waben im windkanal, or honeycomb in the wind tunnel in English, demonstrates a dynamic interplay between nature-inspired design and cutting-edge engineering. This article delves into how this innovative approach transforms product design across various industries, enhancing performance, efficiency, and sustainability.

Beyond its immediate applications in industrial design, the honeycomb structure's role in wind tunnel testing underscores broader implications for environmental sustainability. The efficiencies gained from such testing help reduce resource consumption and carbon footprints across industries. By drawing on nature’s blueprint, the honeycomb structure exemplifies how biomimicry can solve modern engineering challenges, steering the global market towards greener technologies. Credibility in this context comes from the sheer volume of research and testing conducted by institutions renowned for their contribution to engineering advancements. Studies published in journals such as the Journal of Fluid Mechanics and findings presented at international aerodynamics conferences provide a strong foundation for the techniques discussed here. Professionals and enthusiasts seeking to implement or learn more about honeycomb structures in wind tunnel applications should consider attending workshops and certification courses offered by leading engineering institutions. These opportunities provide firsthand experience with cutting-edge technologies and methodologies, enhancing both theoretical knowledge and practical skills. In conclusion, the concept of waben im windkanal represents much more than a technical innovation; it's a bridge connecting natural design principles with future-forward engineering. By embracing this approach, industries not only improve their products in terms of performance and efficiency but also contribute to a more sustainable and responsible usage of resources. As advancements in materials and testing methodologies continue to evolve, the potential applications for honeycomb structures in wind tunnel testing will expand, securing a pivotal role in the landscape of modern product development.

Beyond its immediate applications in industrial design, the honeycomb structure's role in wind tunnel testing underscores broader implications for environmental sustainability. The efficiencies gained from such testing help reduce resource consumption and carbon footprints across industries. By drawing on nature’s blueprint, the honeycomb structure exemplifies how biomimicry can solve modern engineering challenges, steering the global market towards greener technologies. Credibility in this context comes from the sheer volume of research and testing conducted by institutions renowned for their contribution to engineering advancements. Studies published in journals such as the Journal of Fluid Mechanics and findings presented at international aerodynamics conferences provide a strong foundation for the techniques discussed here. Professionals and enthusiasts seeking to implement or learn more about honeycomb structures in wind tunnel applications should consider attending workshops and certification courses offered by leading engineering institutions. These opportunities provide firsthand experience with cutting-edge technologies and methodologies, enhancing both theoretical knowledge and practical skills. In conclusion, the concept of waben im windkanal represents much more than a technical innovation; it's a bridge connecting natural design principles with future-forward engineering. By embracing this approach, industries not only improve their products in terms of performance and efficiency but also contribute to a more sustainable and responsible usage of resources. As advancements in materials and testing methodologies continue to evolve, the potential applications for honeycomb structures in wind tunnel testing will expand, securing a pivotal role in the landscape of modern product development.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025