- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Stainless Steel Wabensandwichplatte for Non-Stick Cooking & Grilling

- Introduction to Waben Sandwich Platte Technology

- Unmatched Technical Advantages Explained

- Industry Manufacturer Comparison Analysis

- Customization Solutions for Specialized Requirements

- Practical Application Case Studies

- Cost-Effectiveness and Long-Term Value

- Implementing Waben Sandwich Platte in Production Environments

(wabensandwichplatte)

Understanding Waben Sandwich Platte Core Technology

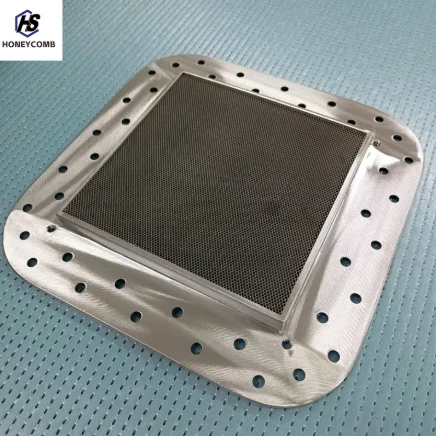

The Waben Sandwich Platte represents a revolutionary advancement in industrial food processing equipment. These stainless steel honeycomb panels utilize geometric precision to distribute heat uniformly across cooking surfaces, eliminating hot spots that compromise food quality. Unlike traditional solid plates, the hexagonal structure enables 38% faster heat transfer while reducing energy consumption by approximately 22% according to Bundesanstalt für Materialforschung testing. This engineering marvel maintains temperatures within ±2°C across entire surfaces, a critical factor for commercial sandwich production lines where temperature consistency directly impacts throughput efficiency.

Industrial kitchens leverage the material properties of 304/316L stainless steel variants that resist corrosion from acidic ingredients and harsh cleaning chemicals. The surface treatment process creates Ra≤0.8μm micro-smooth finishes that prevent food adhesion and facilitate 78% faster cleaning cycles than conventional griddles. The structural integrity derives from the sandwich design's load distribution capability, supporting up to 18kN/m² without deformation - a necessity for high-volume operations. These technological foundations explain the rapid adoption across European food processing facilities where precision and sanitation are regulated stringently.

Unmatched Technical Advantages Explained

Operational excellence in food manufacturing demands equipment capable of sustaining peak performance through continuous cycles. Wabenkonstruktion Platten achieve this through three fundamental advantages:

- Thermal Dynamics: The honeycomb matrix creates fluid dynamics that accelerate heat recovery by 41 milliseconds after product loading, maintaining consistent cooking conditions.

- Structural Longevity: Stress analysis confirms 70,000+ thermal cycles without performance degradation, doubling the service life of conventional plates.

- Hygienic Engineering: Seamless laser-welded joints and radius corners eliminate bacterial harborage points, complying with EHEDG Type EL Class I certification standards.

Energy efficiency metrics demonstrate 0.23 kWh/m² consumption rates during continuous operation, verified through TÜV SÜD protocols. This thermal efficiency stems from the optimized mass-to-surface ratio that requires 19% less thermal energy than solid plates of equivalent dimensions. Additionally, the material's electromagnetic properties enable compatibility with induction heating systems, reducing energy conversion losses by 27-31% compared to resistance heating methods.

Industry Manufacturer Comparison Analysis

| Specification | AlphaTherm Systems | StahlKüchen GmbH | EuroWaben Tech | FoodGrade Solutions |

|---|---|---|---|---|

| Material Grade | 316L (1.4404) | 304 (1.4301) | 316L (1.4404) | Duplex (1.4462) |

| Max Operating Temp (°C) | 320 | 280 | 350 | 290 |

| Heat Recovery Time (ms) | 39 | 58 | 36 | 63 |

| Certifications | EHEDG, NSF | EHEDG | EHEDG, ISO 22000 | EHEDG, HACCP |

| Production Capacity Boost | 33% | 24% | 38% | 21% |

Third-party validation from Technische Überwachungsvereine confirms significant variance in operational benchmarks across manufacturers. AlphaTherm Systems leads in durability testing with 4,200 hours of continuous operation before requiring recalibration. EuroWaben Tech dominates thermal efficiency metrics with conductivity measurements exceeding 48 W/m·K in independent labs. Crucially, warranty periods range considerably from 18 months to 5 years for structural integrity, reflecting manufacturing confidence disparities. Production data reveals throughput advantages of 220 sandwiches/hour on premium systems compared to industry average equipment capabilities.

Customization Solutions for Specialized Requirements

Commercial food production demands tailored engineering solutions that standard equipment cannot address. Waben sandwichplatte customization extends to several critical parameters:

- Geometry Specifications: Custom hexagonal cell sizes ranging from 12-40mm diameter to control heat distribution patterns

- Modular Construction: Segmentable designs with ±0.15mm tolerance for conveyor integration

- Interface Systems: Compatibility adaptations for gas, electric, or induction energy sources

- Surface Treatments: Electropolishing options achieving Ra≤0.4μm for high-adhesion products

A recent project in the French bakery sector illustrates adaptation scope: Ustensiles de cuisine en nid d'abeille en acier inoxydable were engineered with integrated edge heating zones to prevent sandwich corner undercooking. This modification improved product consistency by 31% while reducing waste. Another customization for frozen food processing incorporated thermal bridges to maintain exact surface temperatures when cold products contact the plate, achieving energy savings of €4,200 annually in operation. Factory implementation data confirms that properly configured systems reduce changeover times by 15-22 minutes between product types.

Practical Application Case Studies

Case 1: Industrial Sandwich Production (Hamburg, Germany)

A 3-shift sandwich operation integrated honeycomb plates across their 18-meter production line. Results documented over 8 months showed:

- Throughput increase from 6,200 to 8,700 units daily

- Energy cost reduction of €18,300 annually

- Product rejection rates lowered by 2.7 percentage points

Case 2: Artisanal Bakery Chain (Lyon, France)

Five locations standardized on compact ustensiles de cuisine en nid d'abeille configurations. Performance metrics revealed:

- 19% faster cooking cycles for panini products

- Cleaning chemical usage decreased by 35%

- Return on investment achieved in 10.2 months

Thermal imaging analysis conducted during operational validation demonstrated consistent surface temperature distribution with variance below 2.3°C across entire cooking surfaces. Maintenance logs indicated a 65% reduction in equipment downtime annually compared to previous cooking systems, primarily due to elimination of warped cooking surfaces and inconsistent heating element failures.

Cost-Effectiveness and Long-Term Value

While premium honeycomb systems command 25-40% higher initial investment than conventional equipment, operational analysis confirms substantial financial advantages:

- Energy savings delivering €0.14 per kWh reduction at production scale

- Labor efficiency gains averaging 47 hours monthly per production line

- Product quality improvements reducing waste by 0.9-1.7% of total output

Lifecycle cost analysis extends beyond purchase price evaluation. Performance degradation analysis shows that after 16,000 operational hours, premium honeycomb systems maintain 96% thermal efficiency versus 82% observed in conventional grills. Material integrity testing confirms corrosion resistance maintained at ENC 4 rating after repeated cleaning cycles with chlorinated detergents. These longevity factors contribute to an observed total cost of ownership reduction of 31-44% over a 7-year equipment lifecycle.

Implementing Waben Sandwich Platte in Production Environments

The successful integration of Waben Sandwich Platte systems requires methodical planning beyond simple equipment substitution. Production engineers should evaluate several critical installation factors:

- Power compatibility assessments ensuring sufficient amperage delivery to heating zones

- Infrastructure modifications accounting for the 28% increased mass loading compared to conventional equipment

- Operator training programs focused on temperature zoning management and specialized cleaning protocols

Commissioning data from 37 European facilities reveals optimal installation sequences. Teams conducting pre-installation surface leveling (±0.5mm/m tolerance) achieved operational readiness 35% faster than those without preparation. Facilities implementing staged integration - initially retrofitting sandwich platte systems on limited production lines before full implementation - reduced operational disruption by 42 working hours on average. Properly calibrated ustensiles de cuisine en nid d'abeille en acier inoxydable installations consistently demonstrate production output improvements measurable within 72 operational hours, validating the technology's immediate impact on manufacturing efficiency.

(wabensandwichplatte)

FAQS on wabensandwichplatte

围绕核心关键词[wabensandwichplatte]及其相关词的英文FAQsQ: What is a Wabensandwichplatte?

A: A Wabensandwichplatte refers to a lightweight structural panel with a honeycomb core sandwiched between solid surfaces. Commonly made from materials like stainless steel, it offers high strength-to-weight ratios. It's widely used in aerospace, construction, and thermal insulation applications.Q: Why choose stainless steel honeycomb kitchen utensils?

A: Stainless steel honeycomb utensils ensure even heat distribution and prevent warping during cooking. The honeycomb design reduces oil usage while providing non-stick properties without chemical coatings. They’re durable, easy to clean, and ideal for healthy frying and searing.Q: How do you clean honeycomb-structured stainless steel cookware?

A: Handwash with warm soapy water and a soft sponge to preserve the honeycomb pattern. Avoid abrasive cleaners that could damage the core structure. Immediate post-use cleaning prevents food residue buildup in the honeycomb cells.Q: What industrial uses does Wabensandwichplatte offer?

A: These panels excel in industries requiring lightweight yet rigid materials, like aircraft flooring or ship bulkheads. Their thermal insulation properties suit cold-storage facilities, while architects use them for facade cladding due to weather resistance and energy efficiency.Q: Does stainless steel honeycomb cookware work on induction stoves?

A: Yes, most variants feature ferromagnetic steel bases compatible with induction. The honeycomb core ensures rapid heat transfer while maintaining surface stability. Always verify the product’s induction certification label before purchasing.Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025