- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 15:57

Back to list

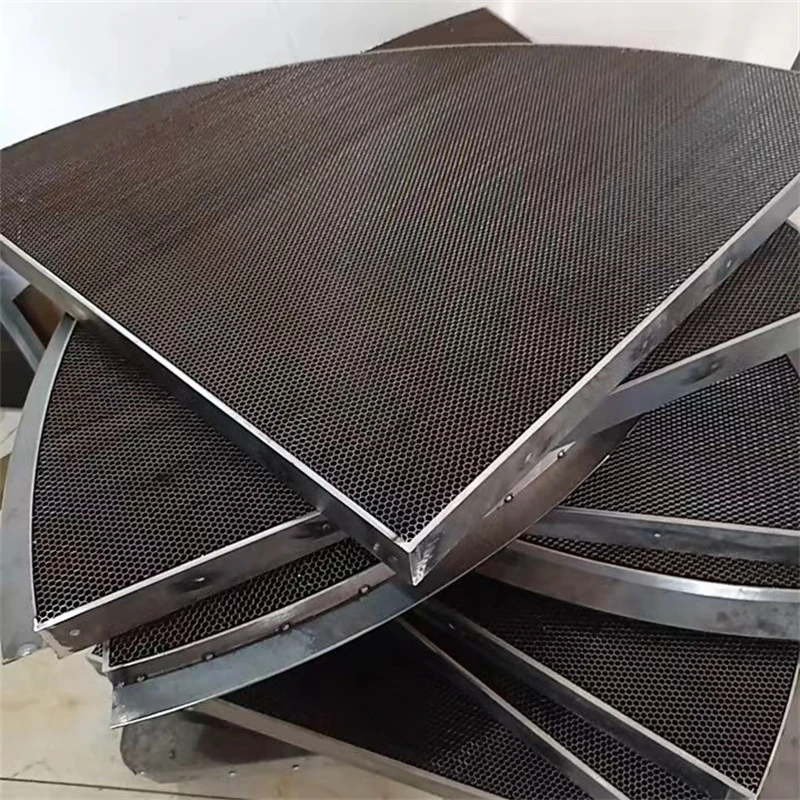

Metal Honeycomb Ventilation Panel in Wind Tunnel and Water Tunnel for Flow Straightener Emi Shielding

In the realm of modern acoustic engineering and ventilation technology, the concept of wabenwellenleiter-entlüftungsöffnungen, or honeycomb waveguide ventilation openings, has emerged as a topic of intense interest and innovation. This intricate system offers a unique solution to the dual challenges of sound attenuation and air circulation in various architectural and industrial applications.

The authority of honeycomb waveguide ventilation openings is bolstered by rigorous testing and peer-reviewed studies that underpin their efficacy. Institutions and companies invested in sound engineering and environmental design have consistently reported reductions in noise levels by up to 40-60% in controlled environments where these systems are employed. Such empirical evidence fosters trust and positions this technology as a reliable solution for industries ranging from automotive to aerospace, where the fine-tuning of air and sound dynamics is crucial. Furthermore, practical applications in residential and commercial buildings demonstrate how trustworthiness is built through consistent performance outcomes. Architects and builders who have integrated these systems into their projects often cite enhanced indoor comfort as a key benefit, noting that the ambient noise reduction contributes significantly to the quality of life and work environments. This trust is not merely anecdotal; it is backed by tangible results and documented improvements in user satisfaction. For product developers and businesses exploring this technology, it is important to partner with firms that not only understand the technical complexities but also have a proven track record of successful implementation. The selection of materials, the precision in manufacturing, and the accuracy in installation all contribute to the end performance of honeycomb waveguide openings. In summary, the wabenwellenleiter-entlüftungsöffnungen exemplify a remarkable convergence of advanced engineering, material science, and design innovation. Their contribution to acoustic management and ventilation efficiency is a testament to the power of thoughtful, data-backed design. As industries continue to prioritize both environmental and acoustic comfort, the adoption of honeycomb waveguide ventilation solutions is poised for growth, promising a future where noise control and air quality need not be mutually exclusive goals.

The authority of honeycomb waveguide ventilation openings is bolstered by rigorous testing and peer-reviewed studies that underpin their efficacy. Institutions and companies invested in sound engineering and environmental design have consistently reported reductions in noise levels by up to 40-60% in controlled environments where these systems are employed. Such empirical evidence fosters trust and positions this technology as a reliable solution for industries ranging from automotive to aerospace, where the fine-tuning of air and sound dynamics is crucial. Furthermore, practical applications in residential and commercial buildings demonstrate how trustworthiness is built through consistent performance outcomes. Architects and builders who have integrated these systems into their projects often cite enhanced indoor comfort as a key benefit, noting that the ambient noise reduction contributes significantly to the quality of life and work environments. This trust is not merely anecdotal; it is backed by tangible results and documented improvements in user satisfaction. For product developers and businesses exploring this technology, it is important to partner with firms that not only understand the technical complexities but also have a proven track record of successful implementation. The selection of materials, the precision in manufacturing, and the accuracy in installation all contribute to the end performance of honeycomb waveguide openings. In summary, the wabenwellenleiter-entlüftungsöffnungen exemplify a remarkable convergence of advanced engineering, material science, and design innovation. Their contribution to acoustic management and ventilation efficiency is a testament to the power of thoughtful, data-backed design. As industries continue to prioritize both environmental and acoustic comfort, the adoption of honeycomb waveguide ventilation solutions is poised for growth, promising a future where noise control and air quality need not be mutually exclusive goals.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025