- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 13, 2025 12:50

Back to list

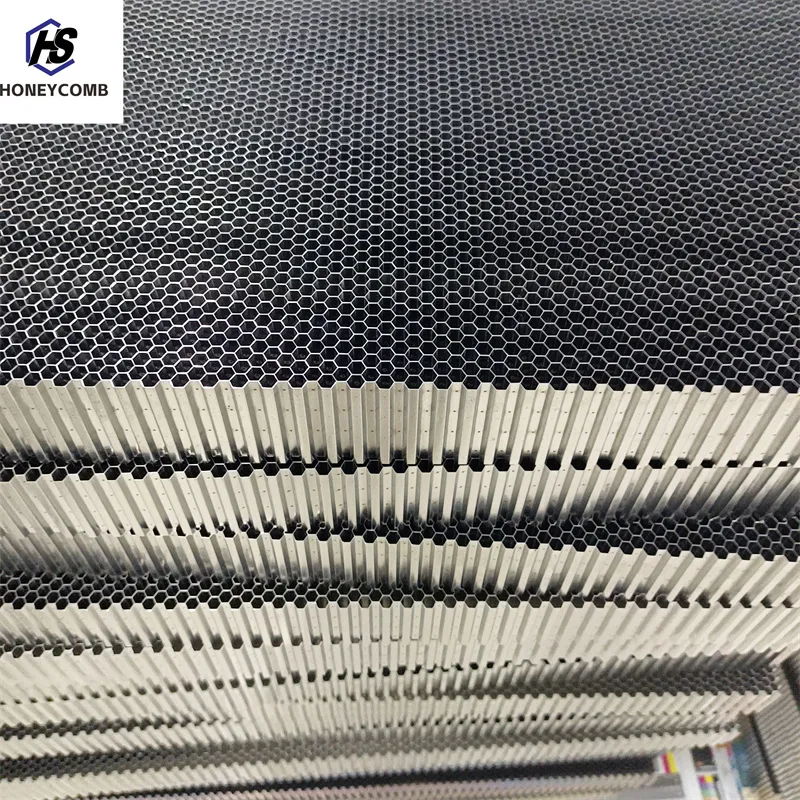

wind tunnel honeycomb

Alloy honeycomb sheets are rapidly making their mark across various industries, offering an unparalleled combination of lightweight strength, flexibility, and durability. These sheets are particularly prominent in aerospace, construction, and automotive sectors, where the demand for high-performance materials is ever-increasing.

Professionals who work with alloy honeycomb sheets frequently highlight their favorable strength-to-weight ratio as a critical factor in their utility. Moreover, ease of machining and customization allows manufacturers to tailor these sheets to specific project requirements, ensuring optimal performance across diverse applications. This adaptability and efficiency lead to cost savings, both in material usage and energy consumption, over traditional full-density materials. From an expert's point of view, the choice of alloy in honeycomb sheets is essential. Aluminum alloys, often preferred for their excellent strength and lightweight characteristics, are the most popular. However, demands for higher performance in extreme conditions have led to the use of titanium and even stainless steel alloys, balancing cost-effectiveness with superior resistance to heat and corrosion. The consistent demand and innovation surrounding alloy honeycomb sheets underscore their importance in modern engineering and design. R&D departments continually seek ways to enhance their properties further, focusing on improving thermal insulation, acoustic performance, and even sustainability by incorporating recyclable materials. As industry standards and environmental considerations evolve, alloy honeycomb sheets are anticipated to be at the forefront of sustainable design solutions. The ongoing research and development, coupled with real-world applications and feedback, not only affirm their current relevance but also promise a future where they might become a staple in new, unexpected ways.

Professionals who work with alloy honeycomb sheets frequently highlight their favorable strength-to-weight ratio as a critical factor in their utility. Moreover, ease of machining and customization allows manufacturers to tailor these sheets to specific project requirements, ensuring optimal performance across diverse applications. This adaptability and efficiency lead to cost savings, both in material usage and energy consumption, over traditional full-density materials. From an expert's point of view, the choice of alloy in honeycomb sheets is essential. Aluminum alloys, often preferred for their excellent strength and lightweight characteristics, are the most popular. However, demands for higher performance in extreme conditions have led to the use of titanium and even stainless steel alloys, balancing cost-effectiveness with superior resistance to heat and corrosion. The consistent demand and innovation surrounding alloy honeycomb sheets underscore their importance in modern engineering and design. R&D departments continually seek ways to enhance their properties further, focusing on improving thermal insulation, acoustic performance, and even sustainability by incorporating recyclable materials. As industry standards and environmental considerations evolve, alloy honeycomb sheets are anticipated to be at the forefront of sustainable design solutions. The ongoing research and development, coupled with real-world applications and feedback, not only affirm their current relevance but also promise a future where they might become a staple in new, unexpected ways.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025