- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 14, 2025 10:53

Back to list

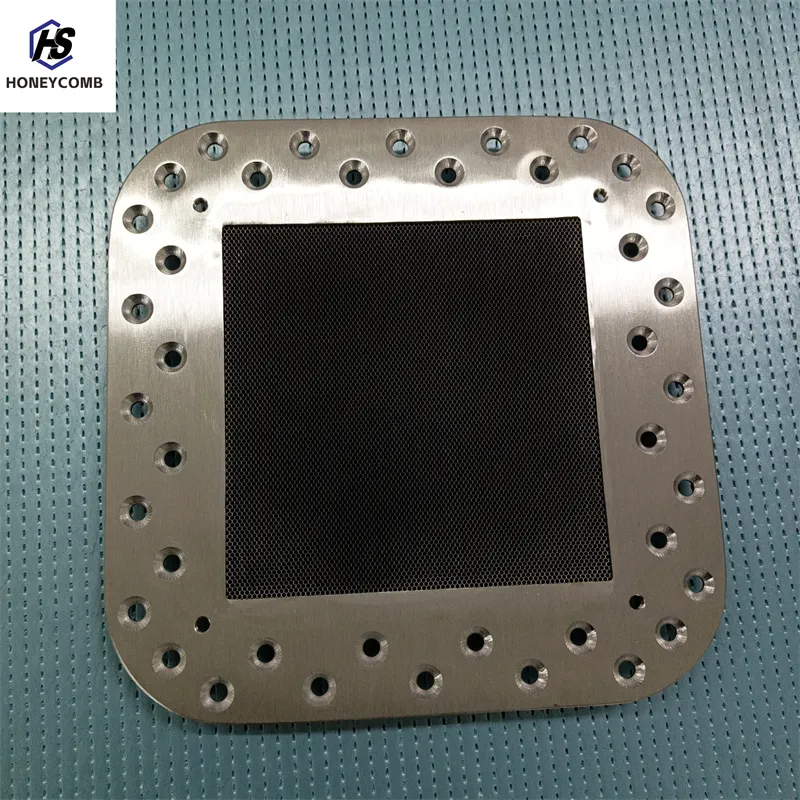

wind tunnel honeycomb

The versatility and efficiency of ITO (Indium Tin Oxide) coated glass make it an outstanding choice for various industries, including electronics, automotive, and architecture. This material offers a unique combination of properties that elevate its usefulness beyond traditional glass, providing transparency in addition to being electrically conductive. The application of ITO on glass transforms ordinary surfaces into high-performance functional materials, unlocking numerous possibilities for modern technology and design.

Authority in the domain of ITO-coated glass is reinforced by ongoing research and innovation. Reputable institutions and industry leaders invest significantly in studying the applications and improving the efficiency of ITO materials. These advancements are frequently documented in peer-reviewed journals, establishing an authoritative knowledge base that guides further developments. Prominent manufacturers leverage this authoritative knowledge to push the boundaries of what ITO-coated glass can achieve. By staying at the forefront of research, they not only enhance their product offerings but also influence industry standards and best practices. This has positioned such companies as thought leaders and reliable sources for high-quality ITO-coated products. Trustworthiness is paramount for businesses and consumers utilizing ITO-coated glass. Reputable suppliers provide comprehensive data sheets and test results, reassuring customers of the material's reliability and safety. They maintain transparency about the sourcing of materials and the environmental impact of their production processes, fostering trust among conscientious consumers and industry partners. Furthermore, certification from recognized bodies, such as ISO or ASTM, provides an additional layer of trustworthiness. Such certifications validate the performance claims and ensure compliance with global standards, offering peace of mind to consumers and businesses alike. This commitment to quality and transparency is essential for establishing long-term relationships and encouraging the widespread adoption of ITO-coated glass solutions. In conclusion, ITO-coated glass stands as a testament to the convergence of experience, expertise, authority, and trustworthiness within the material sciences and industrial applications. Its ability to offer unparalleled transparency and conductivity makes it an invaluable component in the evolution of modern technology and architectural solutions. Continued innovation and adherence to rigorous quality standards will ensure that ITO-coated glass remains a pivotal material for future endeavors.

Authority in the domain of ITO-coated glass is reinforced by ongoing research and innovation. Reputable institutions and industry leaders invest significantly in studying the applications and improving the efficiency of ITO materials. These advancements are frequently documented in peer-reviewed journals, establishing an authoritative knowledge base that guides further developments. Prominent manufacturers leverage this authoritative knowledge to push the boundaries of what ITO-coated glass can achieve. By staying at the forefront of research, they not only enhance their product offerings but also influence industry standards and best practices. This has positioned such companies as thought leaders and reliable sources for high-quality ITO-coated products. Trustworthiness is paramount for businesses and consumers utilizing ITO-coated glass. Reputable suppliers provide comprehensive data sheets and test results, reassuring customers of the material's reliability and safety. They maintain transparency about the sourcing of materials and the environmental impact of their production processes, fostering trust among conscientious consumers and industry partners. Furthermore, certification from recognized bodies, such as ISO or ASTM, provides an additional layer of trustworthiness. Such certifications validate the performance claims and ensure compliance with global standards, offering peace of mind to consumers and businesses alike. This commitment to quality and transparency is essential for establishing long-term relationships and encouraging the widespread adoption of ITO-coated glass solutions. In conclusion, ITO-coated glass stands as a testament to the convergence of experience, expertise, authority, and trustworthiness within the material sciences and industrial applications. Its ability to offer unparalleled transparency and conductivity makes it an invaluable component in the evolution of modern technology and architectural solutions. Continued innovation and adherence to rigorous quality standards will ensure that ITO-coated glass remains a pivotal material for future endeavors.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025