- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 15:45

Back to list

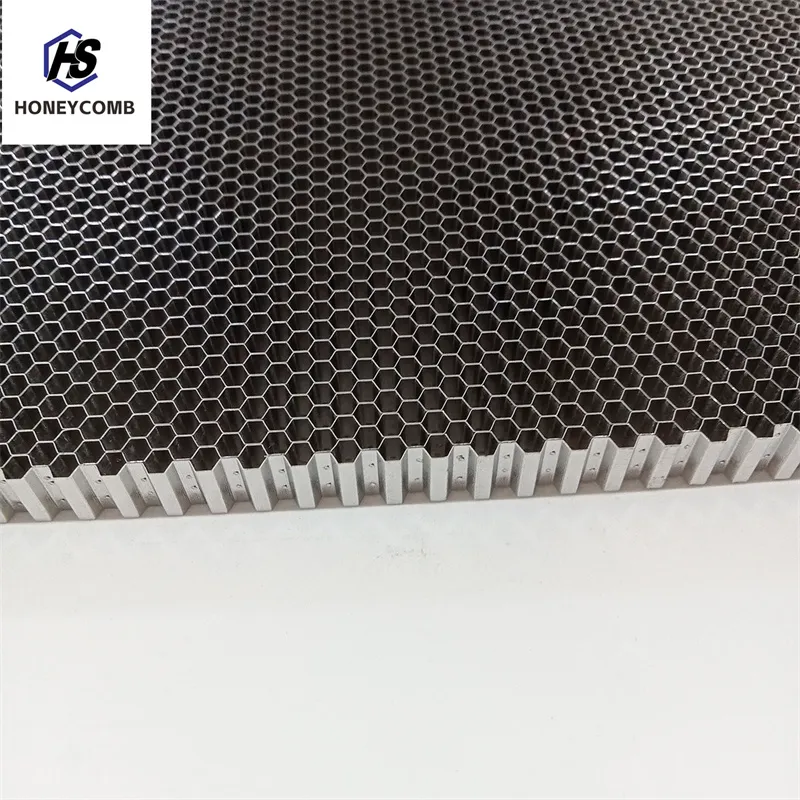

air flow straightener

The heart of honeycomb steel, a term that might not be widely recognized yet, is poised to revolutionize the way we perceive this versatile material. While many associate honeycomb structures with organic constructions, integrating steel into this concept introduces a realm of possibilities for various industries. This innovative fusion not only leverages steel's robustness but also capitalizes on the natural efficiencies inherent in honeycomb designs.

The adoption of honeycomb steel doesn't come without challenges. One significant hurdle is the production process which requires precision and advanced technology to execute correctly. However, with the advancements in manufacturing technology, these obstacles are becoming increasingly manageable. Pioneering companies investing in research and development are likely to overcome these challenges, eventually reducing costs and making honeycomb steel more accessible. Establishing credibility and gaining authority in the field of honeycomb steel involves demonstrating expertise through strategic partnerships with universities and research institutions. Such collaborations can lead to groundbreaking studies and real-world applications that enhance our understanding of this innovative material. By investing in educational partnerships, companies can also foster a new generation of engineers and architects who are familiar with these cutting-edge materials, further cementing their authority in the industry. Consumers and stakeholders must trust the potential of honeycomb steel. Transparency through case studies, pilot projects, and testimonials can provide valuable insights into its real-world applications and benefits. By sharing these experiences and establishing a track record of success, companies can build trust and demonstrate the material's reliability and versatility. In conclusion, the heart of honeycomb steel presents a transformative opportunity across various industries. As the world gravitates towards sustainable and efficient solutions, honeycomb steel could significantly impact how we design, manufacture, and use materials in critical applications. Maintaining a focus on innovation, collaboration, and transparency will be essential as industry leaders leverage this promising technology to shape the future of engineering and construction.

The adoption of honeycomb steel doesn't come without challenges. One significant hurdle is the production process which requires precision and advanced technology to execute correctly. However, with the advancements in manufacturing technology, these obstacles are becoming increasingly manageable. Pioneering companies investing in research and development are likely to overcome these challenges, eventually reducing costs and making honeycomb steel more accessible. Establishing credibility and gaining authority in the field of honeycomb steel involves demonstrating expertise through strategic partnerships with universities and research institutions. Such collaborations can lead to groundbreaking studies and real-world applications that enhance our understanding of this innovative material. By investing in educational partnerships, companies can also foster a new generation of engineers and architects who are familiar with these cutting-edge materials, further cementing their authority in the industry. Consumers and stakeholders must trust the potential of honeycomb steel. Transparency through case studies, pilot projects, and testimonials can provide valuable insights into its real-world applications and benefits. By sharing these experiences and establishing a track record of success, companies can build trust and demonstrate the material's reliability and versatility. In conclusion, the heart of honeycomb steel presents a transformative opportunity across various industries. As the world gravitates towards sustainable and efficient solutions, honeycomb steel could significantly impact how we design, manufacture, and use materials in critical applications. Maintaining a focus on innovation, collaboration, and transparency will be essential as industry leaders leverage this promising technology to shape the future of engineering and construction.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025