- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 16:16

Back to list

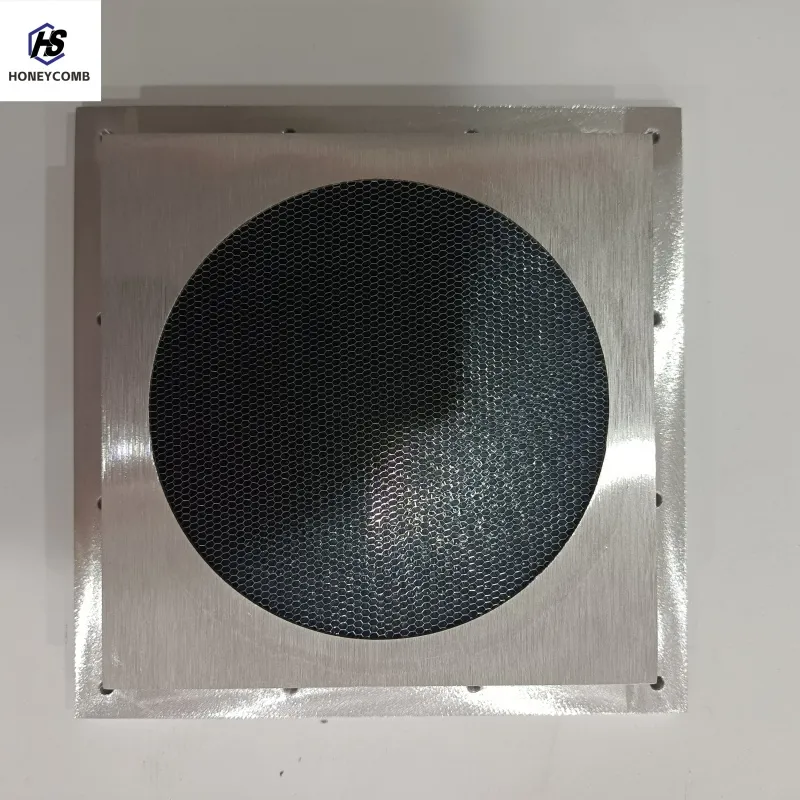

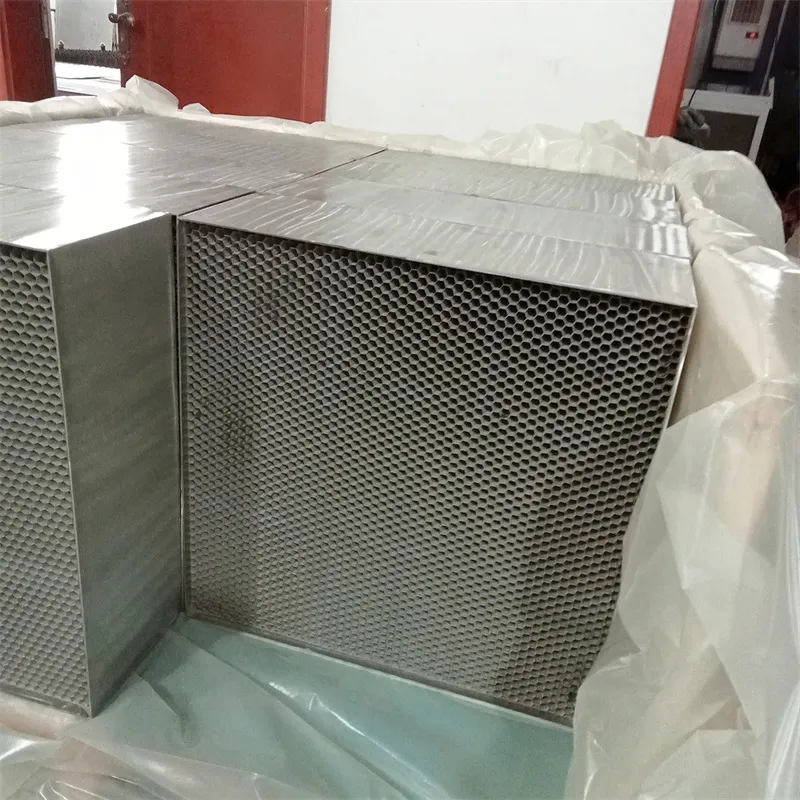

maf air fow straightener

In the dynamic world of materials engineering, honeycomb metal sheets have emerged as an innovative product acclaimed for their structural efficiency and versatility. These honeycomb sheets, inspired by the natural geometric perfection of honeybee hives, consist of hexagonally shaped cells that bestow upon them exceptional strength-to-weight ratios. Their unique structure not only enhances their mechanical properties but also adds to their aesthetic appeal, making them a sought-after option in various industries from aerospace to architecture.

Manufacturers have made strides in broadening the customization opportunities for honeycomb metal sheets, offering a range of materials such as aluminum, stainless steel, and titanium options, catering to specific environmental and strength requirements. Specialized coatings and treatments can further augment properties such as corrosion resistance, extending their usability in harsh outdoor environments or in maritime settings where exposure to moisture and salt is prevalent. The production processes of honeycomb metal sheets underscore their reliability and quality, with precision engineering techniques employed to ensure consistent performance across batches. Certification by relevant industry standards underscores their safety and functionality, fostering trust among clients and end-users alike. Moreover, sustainability is at the forefront of honeycomb metal sheet manufacturing. The efficiency of material use in production minimizes waste, and the recyclability of metals aligns well with ecological goals, thus supporting the global shift towards sustainable development practices. In conclusion, honeycomb metal sheets epitomize the fusion of innovation and practicality. Their widespread adoption across diverse sectors speaks volumes about their versatile nature, and the continual advancements in production and design affirm their place in future developments. Industry experts and end-users alike are witnessing firsthand how these materials transform conventional approaches, proving indispensable in both new and existing architectural and engineering endeavors.

Manufacturers have made strides in broadening the customization opportunities for honeycomb metal sheets, offering a range of materials such as aluminum, stainless steel, and titanium options, catering to specific environmental and strength requirements. Specialized coatings and treatments can further augment properties such as corrosion resistance, extending their usability in harsh outdoor environments or in maritime settings where exposure to moisture and salt is prevalent. The production processes of honeycomb metal sheets underscore their reliability and quality, with precision engineering techniques employed to ensure consistent performance across batches. Certification by relevant industry standards underscores their safety and functionality, fostering trust among clients and end-users alike. Moreover, sustainability is at the forefront of honeycomb metal sheet manufacturing. The efficiency of material use in production minimizes waste, and the recyclability of metals aligns well with ecological goals, thus supporting the global shift towards sustainable development practices. In conclusion, honeycomb metal sheets epitomize the fusion of innovation and practicality. Their widespread adoption across diverse sectors speaks volumes about their versatile nature, and the continual advancements in production and design affirm their place in future developments. Industry experts and end-users alike are witnessing firsthand how these materials transform conventional approaches, proving indispensable in both new and existing architectural and engineering endeavors.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025