- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 14:52

Back to list

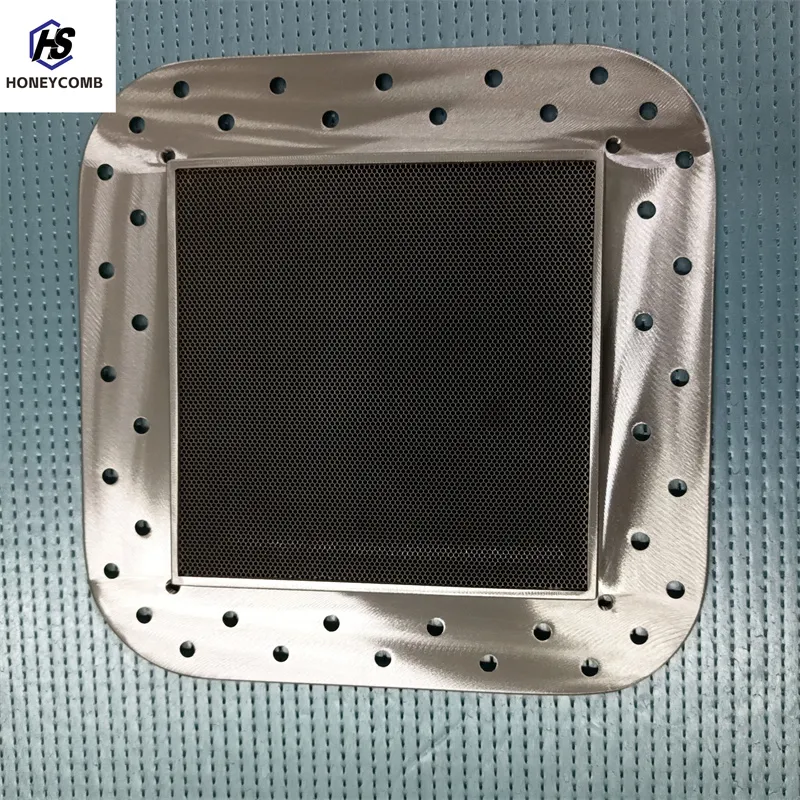

honeycomb strips

Aluminum honeycomb structures are a marvel of modern engineering, marrying lightweight design with unparalleled strength and versatility. Often likened to structures found in nature, such as the hexagonal cells of a honeybee's comb, these innovative materials find applications across various industries, from aerospace to architecture. What truly sets aluminum honeycomb apart is its unique ability to offer superior performance while maintaining an eco-friendly footprint, a factor becoming increasingly critical in today's sustainability-focused environment.

As a testament to their authoritativeness, the adoption of aluminum honeycomb structures has significantly promoted advancements in safety standards and product innovations. Regulatory bodies often look towards this technology when setting new benchmarks for safety and environmental sustainability. Military applications further bolster the credibility of honeycomb panels, as they are integral to the design of protective gear, shelter units, and vehicular armor, offering higher defense capabilities while maintaining maneuverability. Trustworthiness in the application of aluminum honeycomb products is built on decades of successful implementations and ongoing research. Leading manufacturers rigorously test these structures against various parameters, ensuring compliance with stringent quality control standards—essential for industries where failure is not an option. Certification from esteemed international agencies further solidifies consumer confidence in the reliability of these materials. While already impressive, the future of aluminum honeycomb structures is poised for even greater advancements. Innovations in nanotechnology could yield finer control over material properties, enhancing attributes like thermal conductivity and environmental resistance. Moreover, the recycling potential of aluminum signifies a strong alignment with ecological imperatives, fostering a circular economy when the life cycle of these products ends. In summary, aluminum honeycomb structures represent a pinnacle of engineering achievement. Their lightweight, robust nature ensures they meet the demanding needs of modern applications while aligning with growing environmental consciousness. With ongoing technological developments and an unwavering commitment to quality, the scope of aluminum honeycomb in redefining how industries approach design and functionality is boundless, making it a cornerstone of future-oriented engineering solutions.

As a testament to their authoritativeness, the adoption of aluminum honeycomb structures has significantly promoted advancements in safety standards and product innovations. Regulatory bodies often look towards this technology when setting new benchmarks for safety and environmental sustainability. Military applications further bolster the credibility of honeycomb panels, as they are integral to the design of protective gear, shelter units, and vehicular armor, offering higher defense capabilities while maintaining maneuverability. Trustworthiness in the application of aluminum honeycomb products is built on decades of successful implementations and ongoing research. Leading manufacturers rigorously test these structures against various parameters, ensuring compliance with stringent quality control standards—essential for industries where failure is not an option. Certification from esteemed international agencies further solidifies consumer confidence in the reliability of these materials. While already impressive, the future of aluminum honeycomb structures is poised for even greater advancements. Innovations in nanotechnology could yield finer control over material properties, enhancing attributes like thermal conductivity and environmental resistance. Moreover, the recycling potential of aluminum signifies a strong alignment with ecological imperatives, fostering a circular economy when the life cycle of these products ends. In summary, aluminum honeycomb structures represent a pinnacle of engineering achievement. Their lightweight, robust nature ensures they meet the demanding needs of modern applications while aligning with growing environmental consciousness. With ongoing technological developments and an unwavering commitment to quality, the scope of aluminum honeycomb in redefining how industries approach design and functionality is boundless, making it a cornerstone of future-oriented engineering solutions.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025