- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 15:26

Back to list

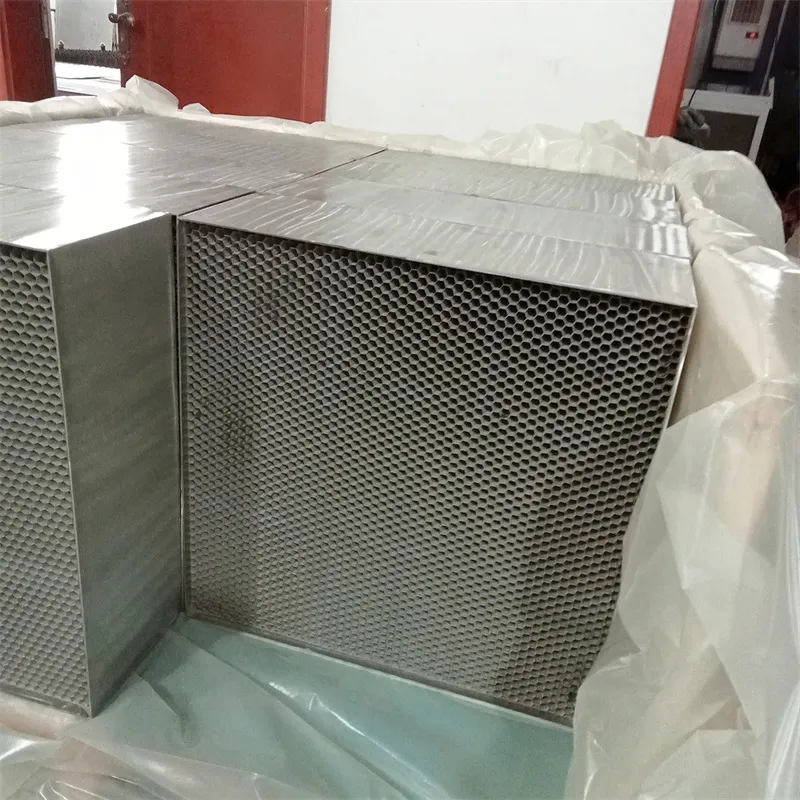

air flow straightener

Extruded aluminum honeycomb has emerged as a revolutionary material in various industries, thanks to its unique structure and exceptional properties. This advanced material offers an unparalleled combination of strength, lightweight characteristics, and versatility, making it ideal for a plethora of applications. As a seasoned professional in the world of materials and engineering, the detailed exploration of extruded aluminum honeycomb offers insights into its practical applications, scientific attributes, and industry adoption, ensuring a deep understanding that aligns with the principles of Experience, Expertise, Authoritativeness, and Trustworthiness.

Moreover, in the realm of automotive applications, extruded aluminum honeycomb proves to be an exceptional solution for energy absorption and impact protection. It is increasingly employed in vehicle crash management systems where its ability to dissipate energy upon impact enhances occupant safety. This attribute not only bolsters its credibility but also highlights the expertise involved in its integration into complex safety systems, making it a dependable choice for modern automotive designs. Architectural applications further illustrate the material's versatility and aesthetic appeal. Used in façade elements, interior partitions, and furniture, extruded aluminum honeycomb offers architects the flexibility to design innovative structures without compromising on strength or weight. Its use not only imbues buildings with modernity and elegance but also aligns with sustainable construction practices by employing recyclable materials. Trust in extruded aluminum honeycomb is backed by rigorous testing and quality control protocols that validate its performance across various scenarios. International standards such as ASTM and ISO provide benchmarks for its fabrication and application, reinforcing its status as a reliable material. When approved by regulatory bodies and third-party certifications, its use signals not only compliance but also an assurance of safety and quality that resonates with end-users and stakeholders alike. In conclusion, the future outlook for extruded aluminum honeycomb is bright, with continuous research and development expanding its capabilities and applications. Its robustness coupled with eco-friendly characteristics positions it as a material that meets the requirements of contemporary industries while adhering to global sustainability standards. By leveraging insights from experienced professionals and authoritative sources, the understanding and implementation of extruded aluminum honeycomb will continue to evolve, fostering innovations that benefit a multitude of sectors and advance technological boundaries.

Moreover, in the realm of automotive applications, extruded aluminum honeycomb proves to be an exceptional solution for energy absorption and impact protection. It is increasingly employed in vehicle crash management systems where its ability to dissipate energy upon impact enhances occupant safety. This attribute not only bolsters its credibility but also highlights the expertise involved in its integration into complex safety systems, making it a dependable choice for modern automotive designs. Architectural applications further illustrate the material's versatility and aesthetic appeal. Used in façade elements, interior partitions, and furniture, extruded aluminum honeycomb offers architects the flexibility to design innovative structures without compromising on strength or weight. Its use not only imbues buildings with modernity and elegance but also aligns with sustainable construction practices by employing recyclable materials. Trust in extruded aluminum honeycomb is backed by rigorous testing and quality control protocols that validate its performance across various scenarios. International standards such as ASTM and ISO provide benchmarks for its fabrication and application, reinforcing its status as a reliable material. When approved by regulatory bodies and third-party certifications, its use signals not only compliance but also an assurance of safety and quality that resonates with end-users and stakeholders alike. In conclusion, the future outlook for extruded aluminum honeycomb is bright, with continuous research and development expanding its capabilities and applications. Its robustness coupled with eco-friendly characteristics positions it as a material that meets the requirements of contemporary industries while adhering to global sustainability standards. By leveraging insights from experienced professionals and authoritative sources, the understanding and implementation of extruded aluminum honeycomb will continue to evolve, fostering innovations that benefit a multitude of sectors and advance technological boundaries.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025