- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 17:10

Back to list

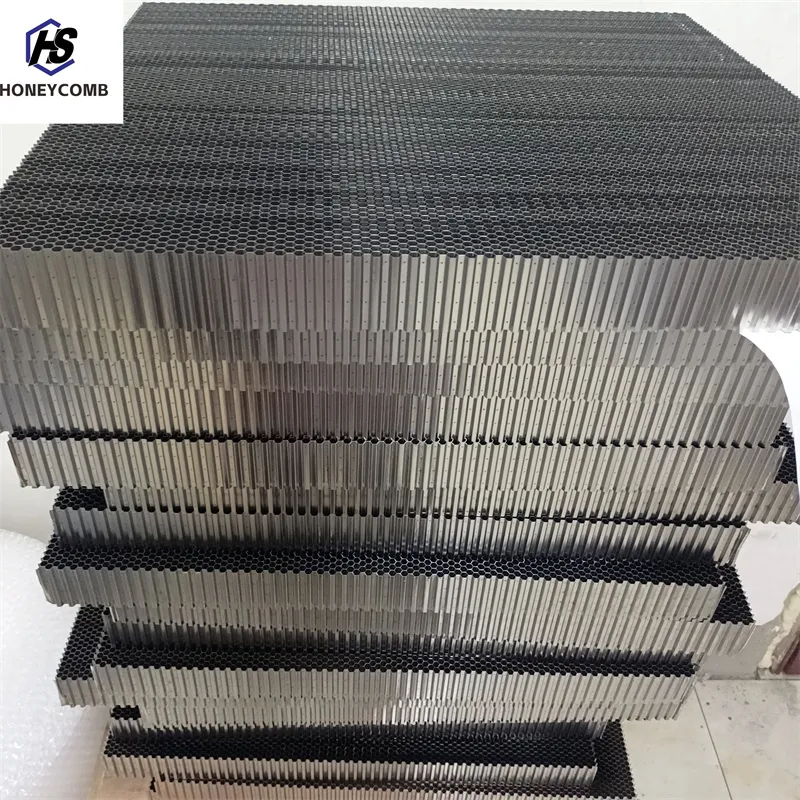

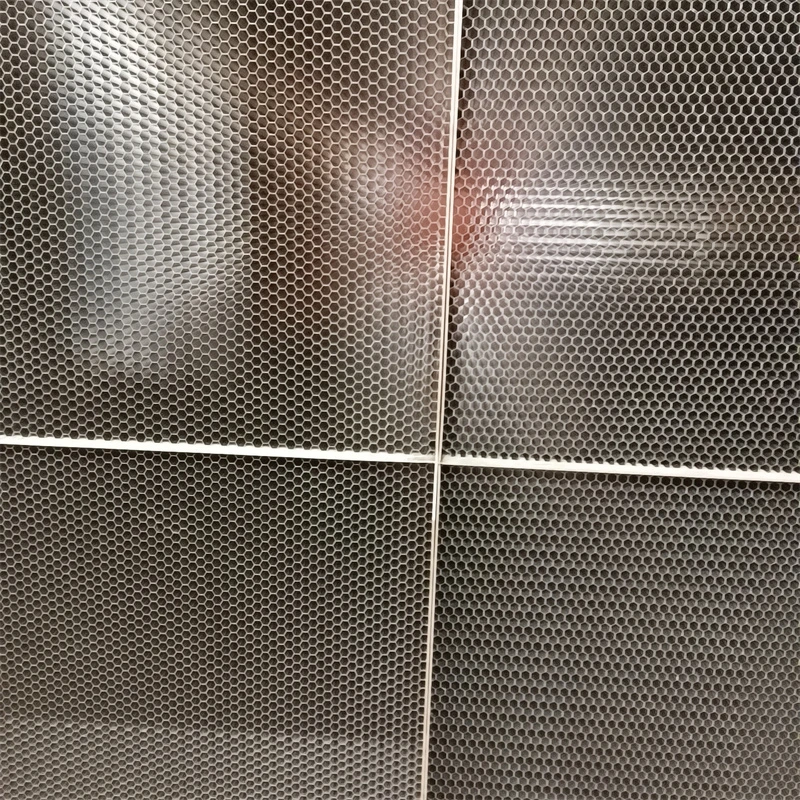

High Shielding Performance 2.0mm Cell Steel Honeycomb Vent For EMI/EMC/RF Shielded

Harnessing cutting-edge technology in aerodynamic testing, honeycomb structures in wind tunnels are revolutionizing the industry with their innovative design and efficiency. These structures have transformed the possibilities for product testing, providing engineers and scientists with unprecedented levels of accuracy, speed, and reliability.

Authoritative figures in the industry underscore that honeycomb structures in wind tunnels are scalable. As technology advances, these structures have been adapted to meet evolving testing requirements and specifications. Such adaptability has reinforced trust among users, positioning honeycomb-design wind tunnels as a reliable choice for both current and future aerodynamic assessments. Studies conducted on aerodynamic efficiency have authenticated the significant improvements brought about by integrating honeycomb structures into workflow processes. Reports indicate a notable enhancement in the precision and fidelity of data collection. Experts and researchers draw upon these findings to reinforce the credibility associated with honeycomb-utilizing facilities. One cannot overlook the environmental advantages offered by these advanced structures. With a growing emphasis on sustainable practices within the engineering domain, honeycombs represent an eco-friendly alternative by reducing the need for excess materials. Engineers and environmental consultants advocate for these structures as they contribute towards a reduction in the carbon footprint associated with aerodynamic testing. The implementation of honeycomb technology results in a system that remains at the forefront of aerodynamic testing advancements. Their usage resonates with the industry's transition towards smarter, eco-efficient solutions and fosters the development of greener technologies. In conclusion, honeycomb structures in wind tunnels have positioned themselves as indispensable tools in the realm of aerodynamic testing. This innovative design not only optimizes testing efficiency and precision but also paves the way for sustainable engineering practices. Trust in honeycomb technology is well-founded, as it continues to set the benchmark in quality and reliability, earning widespread recognition from experts and industry veterans alike.

Authoritative figures in the industry underscore that honeycomb structures in wind tunnels are scalable. As technology advances, these structures have been adapted to meet evolving testing requirements and specifications. Such adaptability has reinforced trust among users, positioning honeycomb-design wind tunnels as a reliable choice for both current and future aerodynamic assessments. Studies conducted on aerodynamic efficiency have authenticated the significant improvements brought about by integrating honeycomb structures into workflow processes. Reports indicate a notable enhancement in the precision and fidelity of data collection. Experts and researchers draw upon these findings to reinforce the credibility associated with honeycomb-utilizing facilities. One cannot overlook the environmental advantages offered by these advanced structures. With a growing emphasis on sustainable practices within the engineering domain, honeycombs represent an eco-friendly alternative by reducing the need for excess materials. Engineers and environmental consultants advocate for these structures as they contribute towards a reduction in the carbon footprint associated with aerodynamic testing. The implementation of honeycomb technology results in a system that remains at the forefront of aerodynamic testing advancements. Their usage resonates with the industry's transition towards smarter, eco-efficient solutions and fosters the development of greener technologies. In conclusion, honeycomb structures in wind tunnels have positioned themselves as indispensable tools in the realm of aerodynamic testing. This innovative design not only optimizes testing efficiency and precision but also paves the way for sustainable engineering practices. Trust in honeycomb technology is well-founded, as it continues to set the benchmark in quality and reliability, earning widespread recognition from experts and industry veterans alike.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025