- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 17:29

Back to list

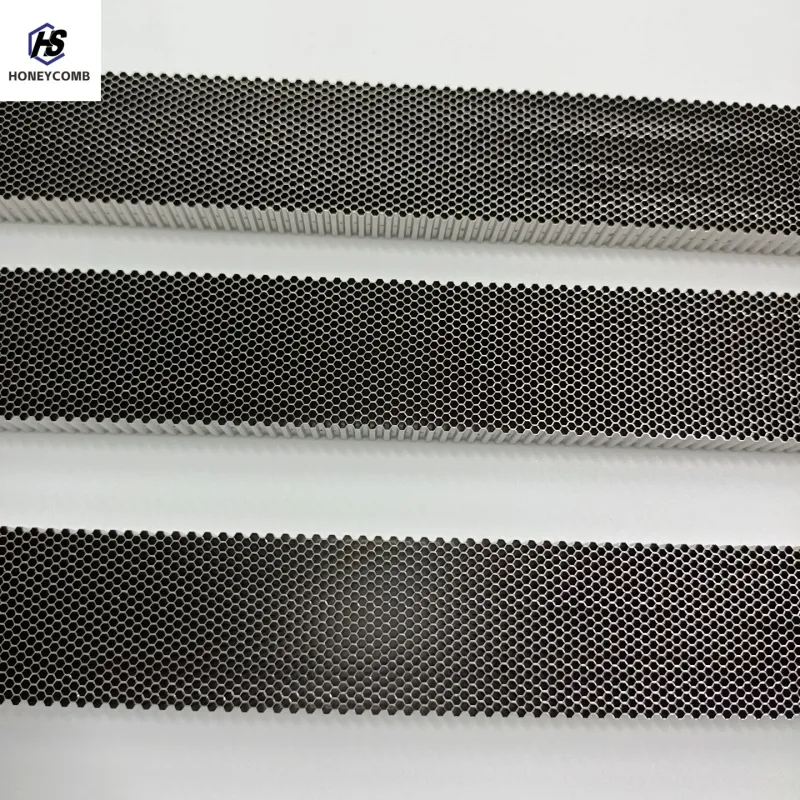

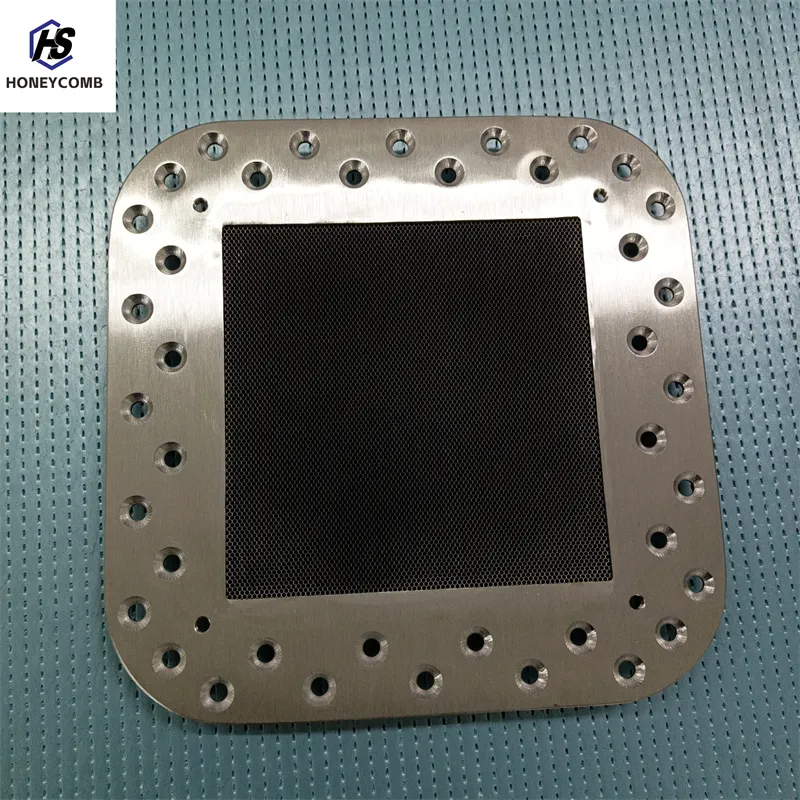

Stainless Steel 304/316L Honeycomb Core for Air Flow Straightener

In the ever-evolving landscape of engineering and technology, mobile wind tunnel design represents a groundbreaking frontier. These innovative systems, pivotal for aerodynamics testing, offer unprecedented flexibility and capabilities that transcend traditional methodologies. The development and deployment of mobile aerodynamic tunnels highlight a confluence of expertise, innovation, and precision engineering.

The authority of mobile wind tunnel technology is rooted in its extensive application across diverse industries. Notably, in the automotive sector, these tunnels provide crucial insights into vehicle aerodynamics directly at manufacturing plants or racing tracks. In aerospace, mobile units allow for the testing of components like wings and fuselage sections in environments more reflective of their actual operating conditions. This adaptability fosters a deeper understanding of aerodynamic forces and their impact on performance, leading to innovations in design and engineering practices. Furthermore, the credibility and trustworthiness of mobile wind tunnel testing have been solidified through rigorous validation and empirical evidence. The insights gained from mobile testing are corroborated with data from conventional wind tunnels, ensuring consistency and reliability. This dual-method validation process is essential for maintaining stringent industry standards and enhancing the technological trust placed in mobile aerodynamics solutions. The deployment of mobile aerodynamic tunnels also fosters collaboration across disciplines and industries. Engineers, designers, and researchers can work in close proximity to testing environments, facilitating swift modifications and iterative testing processes. This collaboration is instrumental in driving innovation and optimizing designs in a fraction of the time required by traditional testing methodologies. In conclusion, mobile wind tunnel design is a significant milestone in contemporary engineering, showcasing unparalleled expertise, authority, and trust across various industries. These systems epitomize the fusion of cutting-edge technology and practical engineering, offering dynamic solutions to complex aerodynamic challenges. As industries increasingly demand precision and flexibility, mobile aerodynamic tunnels will undoubtedly remain at the forefront of technological advancements, paving the way for more innovative and efficient design solutions worldwide.

The authority of mobile wind tunnel technology is rooted in its extensive application across diverse industries. Notably, in the automotive sector, these tunnels provide crucial insights into vehicle aerodynamics directly at manufacturing plants or racing tracks. In aerospace, mobile units allow for the testing of components like wings and fuselage sections in environments more reflective of their actual operating conditions. This adaptability fosters a deeper understanding of aerodynamic forces and their impact on performance, leading to innovations in design and engineering practices. Furthermore, the credibility and trustworthiness of mobile wind tunnel testing have been solidified through rigorous validation and empirical evidence. The insights gained from mobile testing are corroborated with data from conventional wind tunnels, ensuring consistency and reliability. This dual-method validation process is essential for maintaining stringent industry standards and enhancing the technological trust placed in mobile aerodynamics solutions. The deployment of mobile aerodynamic tunnels also fosters collaboration across disciplines and industries. Engineers, designers, and researchers can work in close proximity to testing environments, facilitating swift modifications and iterative testing processes. This collaboration is instrumental in driving innovation and optimizing designs in a fraction of the time required by traditional testing methodologies. In conclusion, mobile wind tunnel design is a significant milestone in contemporary engineering, showcasing unparalleled expertise, authority, and trust across various industries. These systems epitomize the fusion of cutting-edge technology and practical engineering, offering dynamic solutions to complex aerodynamic challenges. As industries increasingly demand precision and flexibility, mobile aerodynamic tunnels will undoubtedly remain at the forefront of technological advancements, paving the way for more innovative and efficient design solutions worldwide.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025