- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 18, 2025 05:23

Back to list

हनीकॉम्ब विंड टनल

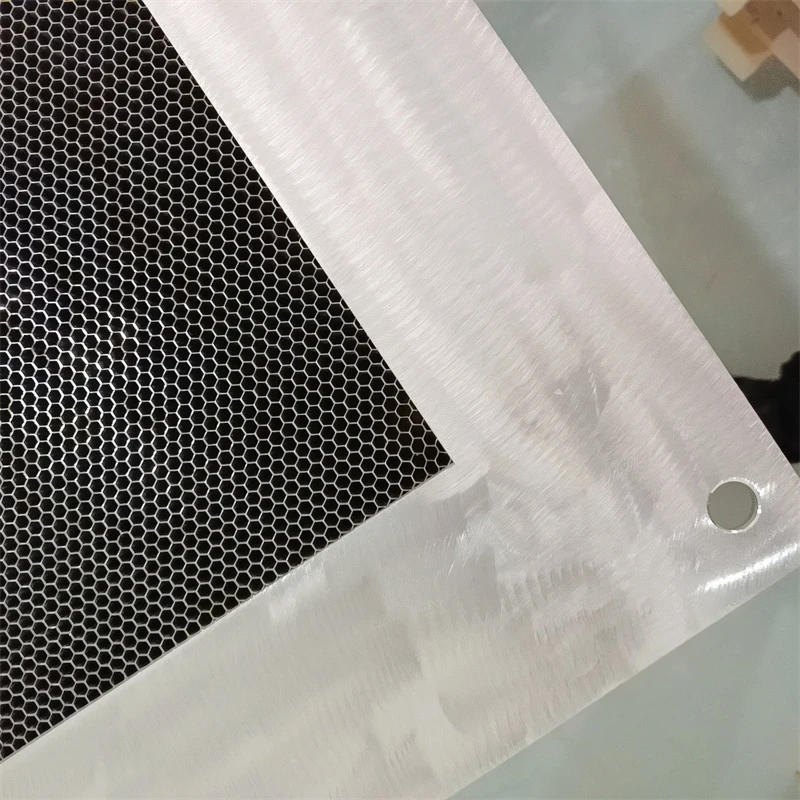

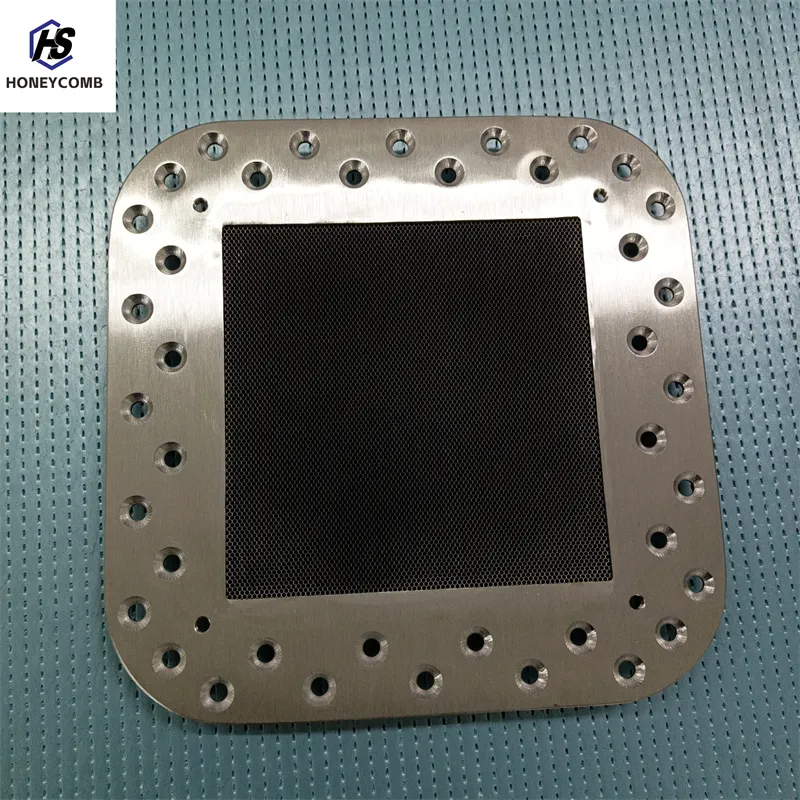

The world of aerodynamics and fluid dynamics has long been fascinated with the utility and function of the हनीकॉम्ब विंड टनल, a revolutionary type of wind tunnel that has transformed product testing. These unique structures are not only pivotal in advancing our understanding of airflow and resistance but also play a crucial role in testing and refining products for varied industries such as automotive, aerospace, and even consumer electronics.

Moreover, the authority of honeycomb wind tunnels extends beyond high-speed transportation sectors. Recently, a major electronics manufacturer utilized this technology to test cooling solutions for high-performance computing systems. These tests ensured that their products met thermal performance standards while maintaining energy efficiency norms. The precision offered by the honeycomb wind tunnel enabled them to identify minute airflow issues detrimental to the cooling process, ensuring their servers remained efficient and reliable under heavy computational loads. Trust in honeycomb wind tunnel data is further elevated by their precision engineering and rigorous calibration processes. These tunnels undergo regular checks and updates to maintain their testing accuracy. Such practices ensure that any insights derived have a solid foundation, boosting trust among stakeholders and clients who rely on these evaluations to make high-stakes decisions. In conclusion, the हनीकॉम्ब विंड टनल is heralded as a beacon of precision and reliability in aerodynamic testing. With unmatched ability to create controlled environments that simulate real-world conditions, honeycomb wind tunnels are indispensable assets for any sector reliant on fluid dynamics. Their consistent results and the level of detail they achieve grant them the stature of an industry standard that others aspire to. Whether for optimizing the aerodynamics of the latest fighter jet or improving the cooling systems of today's fastest computers, the impact of these wind tunnels is irreplaceable.

Moreover, the authority of honeycomb wind tunnels extends beyond high-speed transportation sectors. Recently, a major electronics manufacturer utilized this technology to test cooling solutions for high-performance computing systems. These tests ensured that their products met thermal performance standards while maintaining energy efficiency norms. The precision offered by the honeycomb wind tunnel enabled them to identify minute airflow issues detrimental to the cooling process, ensuring their servers remained efficient and reliable under heavy computational loads. Trust in honeycomb wind tunnel data is further elevated by their precision engineering and rigorous calibration processes. These tunnels undergo regular checks and updates to maintain their testing accuracy. Such practices ensure that any insights derived have a solid foundation, boosting trust among stakeholders and clients who rely on these evaluations to make high-stakes decisions. In conclusion, the हनीकॉम्ब विंड टनल is heralded as a beacon of precision and reliability in aerodynamic testing. With unmatched ability to create controlled environments that simulate real-world conditions, honeycomb wind tunnels are indispensable assets for any sector reliant on fluid dynamics. Their consistent results and the level of detail they achieve grant them the stature of an industry standard that others aspire to. Whether for optimizing the aerodynamics of the latest fighter jet or improving the cooling systems of today's fastest computers, the impact of these wind tunnels is irreplaceable.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025