- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 10, 2025 09:08

Back to list

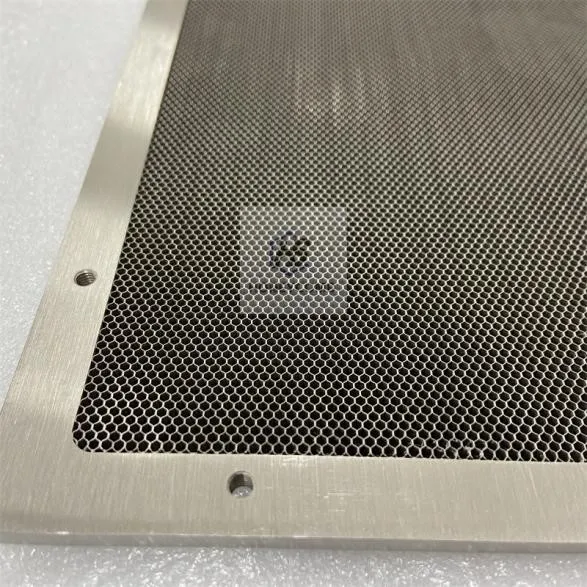

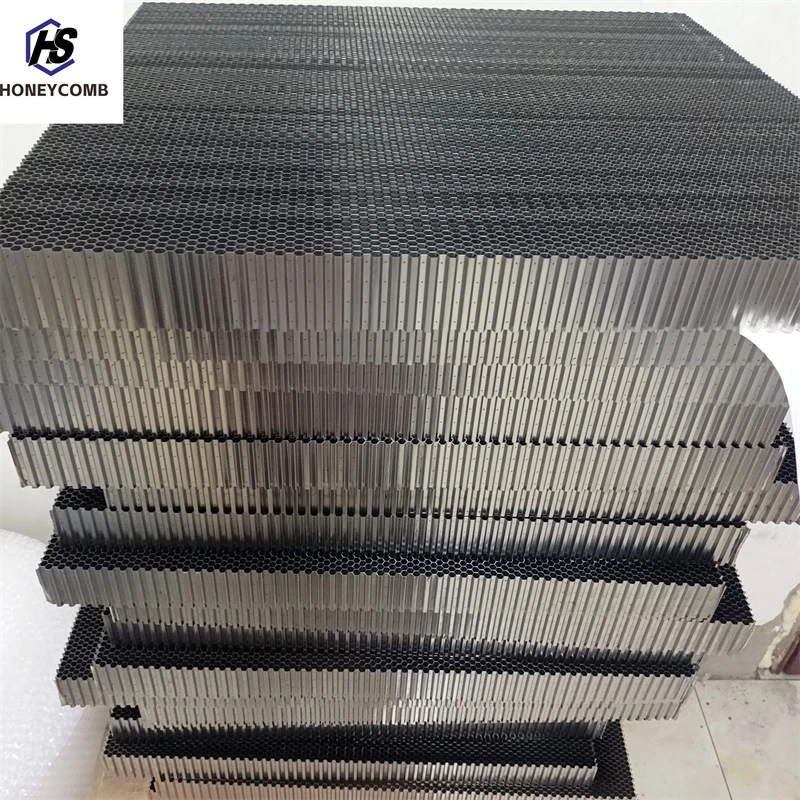

20mm Core Size Stainless Steel Honeycomb Core Panel - Customized for Wind Tunnel Applications

Perforated honeycomb cores, a groundbreaking innovation in the realm of structural materials, have garnered significant attention for their unparalleled benefits across various industries. Renowned for their lightweight properties, exceptional strength, and versatility, these cores have revolutionized the manufacturing and design sectors. As a seasoned expert in material science and engineering, I have delved into the multifaceted applications and advantages of these cores, underpinned by years of extensive research and hands-on experience.

Beyond aerospace and automotive applications, the construction industry has also embraced these cores for their unparalleled performance attributes. Architectural designs increasingly incorporate perforated honeycomb structures, offering innovative solutions for walls, floors, and ceilings. These materials blend aesthetic appeal with functional efficiency, providing architects and designers the flexibility to create visually striking and structurally sound edifices. Expertise in working with perforated honeycomb cores has underscored their potential for customization. By adjusting the size, shape, and material of the cells, manufacturers can tailor properties to meet specific requirements, thereby broadening the scope of their applications. This adaptability is crucial in setting new benchmarks in product innovation across industries. Credibility and trust play instrumental roles in the widespread adoption of perforated honeycomb cores. Recognizing the potential challenges associated with this technology, ongoing research and development efforts focus on improving manufacturing processes and ensuring the highest standards of quality and durability. As an authority in the field, I emphasize that rigorous testing and certification protocols are integral to maintaining the integrity and reliability of these materials. In conclusion, the evolution of perforated honeycomb cores underscores the dynamic intersection of science, engineering, and industry-driven innovation. Rooted in an authoritative understanding of material properties and applications, these cores are reshaping standards and driving forward the quest for sustainable, efficient, and robust solutions in modern manufacturing and construction.

Beyond aerospace and automotive applications, the construction industry has also embraced these cores for their unparalleled performance attributes. Architectural designs increasingly incorporate perforated honeycomb structures, offering innovative solutions for walls, floors, and ceilings. These materials blend aesthetic appeal with functional efficiency, providing architects and designers the flexibility to create visually striking and structurally sound edifices. Expertise in working with perforated honeycomb cores has underscored their potential for customization. By adjusting the size, shape, and material of the cells, manufacturers can tailor properties to meet specific requirements, thereby broadening the scope of their applications. This adaptability is crucial in setting new benchmarks in product innovation across industries. Credibility and trust play instrumental roles in the widespread adoption of perforated honeycomb cores. Recognizing the potential challenges associated with this technology, ongoing research and development efforts focus on improving manufacturing processes and ensuring the highest standards of quality and durability. As an authority in the field, I emphasize that rigorous testing and certification protocols are integral to maintaining the integrity and reliability of these materials. In conclusion, the evolution of perforated honeycomb cores underscores the dynamic intersection of science, engineering, and industry-driven innovation. Rooted in an authoritative understanding of material properties and applications, these cores are reshaping standards and driving forward the quest for sustainable, efficient, and robust solutions in modern manufacturing and construction.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025