- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 10, 2025 08:57

Back to list

сотовый алюминиевый сотовый сердечник

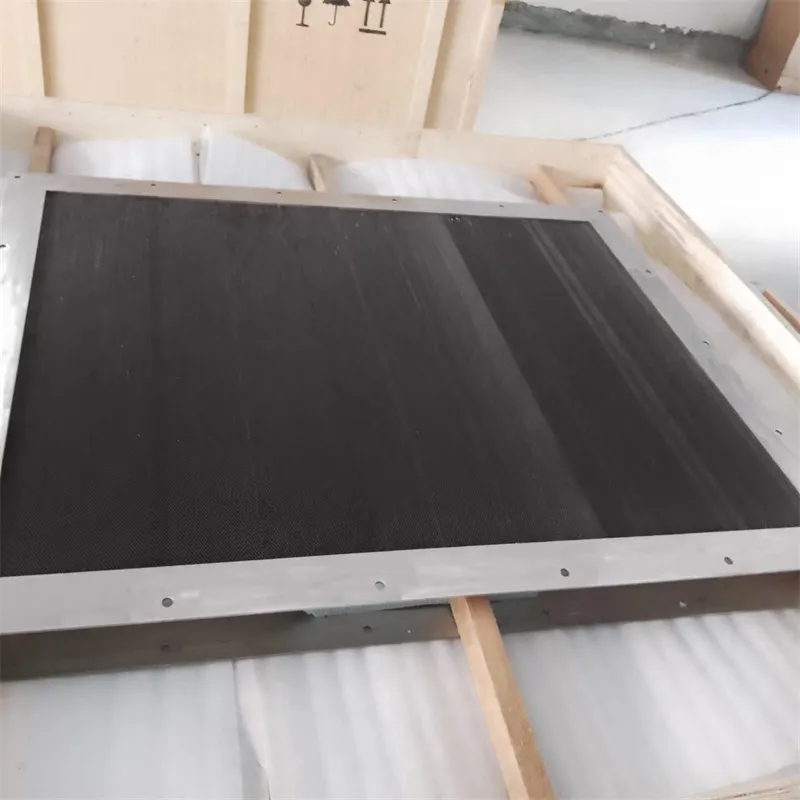

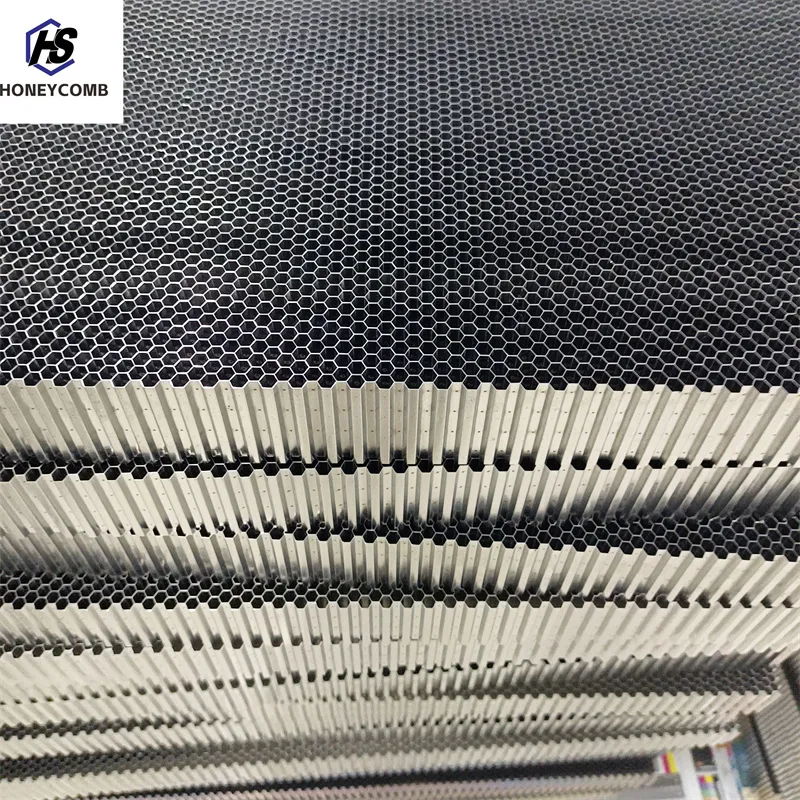

The demand for innovative materials in various industries has been on the rise, with aluminum honeycomb core standing out as a compelling choice. This material offers a harmonious blend of strength, lightweight properties, and versatility, making it indispensable across sectors ranging from aerospace to construction.

In construction, aluminum honeycomb cores are engineering wonders, offering solutions that meet both aesthetic and functional demands. Facades and interior panels incorporating honeycomb cores achieve architectural elegance without sacrificing the building's structural requirements. Architects and builders around the globe trust this material for its blend of modern appeal and enduring performance. The sustainability of aluminum honeycomb core also reinforces its position as a leading material. Aluminum is highly recyclable, and the honeycomb design uses minimal raw material without sacrificing functionality, reducing the carbon footprint of projects utilizing it. This aspect aligns with global sustainability goals, making it a preferred option for environmentally conscious companies and consumers. Moreover, the ease of customization provided by aluminum honeycomb core materials allows manufacturers and designers to cater to specific needs and preferences. This versatility expands its application scope, from high-performance sporting equipment to avant-garde furniture design, offering endless possibilities for innovation. To sum up, the aluminum honeycomb core is not just another material choice but a strategic component that enhances product performance, safety, and sustainability. Its wide-ranging applications and adaptability make it a cornerstone of modern engineering solutions. For businesses and industries aiming to leverage cutting-edge materials, aluminum honeycomb core presents a compelling narrative of efficiency, reliability, and forward-thinking innovation.

In construction, aluminum honeycomb cores are engineering wonders, offering solutions that meet both aesthetic and functional demands. Facades and interior panels incorporating honeycomb cores achieve architectural elegance without sacrificing the building's structural requirements. Architects and builders around the globe trust this material for its blend of modern appeal and enduring performance. The sustainability of aluminum honeycomb core also reinforces its position as a leading material. Aluminum is highly recyclable, and the honeycomb design uses minimal raw material without sacrificing functionality, reducing the carbon footprint of projects utilizing it. This aspect aligns with global sustainability goals, making it a preferred option for environmentally conscious companies and consumers. Moreover, the ease of customization provided by aluminum honeycomb core materials allows manufacturers and designers to cater to specific needs and preferences. This versatility expands its application scope, from high-performance sporting equipment to avant-garde furniture design, offering endless possibilities for innovation. To sum up, the aluminum honeycomb core is not just another material choice but a strategic component that enhances product performance, safety, and sustainability. Its wide-ranging applications and adaptability make it a cornerstone of modern engineering solutions. For businesses and industries aiming to leverage cutting-edge materials, aluminum honeycomb core presents a compelling narrative of efficiency, reliability, and forward-thinking innovation.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025