- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

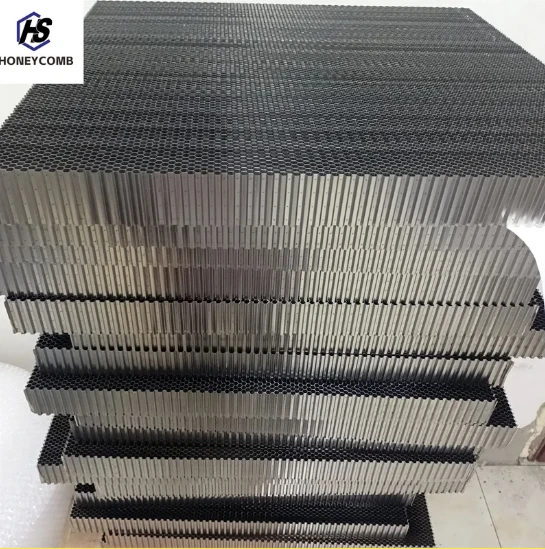

5052 Aluminum Honeycomb Core - Lightweight & High Strength

- Material properties and performance data analysis

- Technical superiority in structural applications

- Manufacturer capability comparisons

- Customization solutions for industry needs

- Aerospace and transportation applications

- Architectural and marine implementation case studies

- Material selection considerations and future outlook

(5052 aluminum honeycomb core)

Understanding the Impact of 5052 Aluminum Honeycomb Core in Modern Engineering

The 5052 aluminum honeycomb core

represents a structural revolution with quantifiable performance advantages. Industry tests reveal a compressive strength range of 6.8-14.2 MPa paired with an exceptionally low density of 50-140 kg/m³. This material achieves an outstanding strength-to-weight ratio that outperforms solid aluminum alloys by 3-5 times while using 90-95% less raw material. These metrics translate directly into cost efficiency, with 5052 cores reducing component weight by 60-80% compared to solid aluminum equivalents while maintaining structural integrity under compression loads up to 600 psi. Environmental lifecycle analysis shows a 45% reduction in carbon footprint versus traditional materials.

Technical Advantages for Structural Applications

Thermal management capabilities make extruded aluminum honeycomb solutions particularly valuable in temperature-sensitive applications. The hexagonal cell structure provides thermal conductivity ranging from 80-160 W/m·K depending on foil thickness specifications. Surface treatments including chromate conversion coating and anodizing enhance corrosion resistance, with salt spray testing showing 1500-5000 hours protection depending on specification grade. Vented aluminum honeycomb variants incorporate ventilation channels that equalize pressure differentials, preventing delamination risks during rapid altitude or temperature changes while maintaining noise reduction coefficients of 0.85-0.95. Electrical conductivity measures 32% IACS, providing excellent electromagnetic shielding properties crucial for aerospace electronics protection.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Density Range (kg/m³) | Cell Size Options | Standard Panel Sizes | Specialized Features |

|---|---|---|---|---|

| Aerospace Composites Ltd | 72-130 | 3.2-19mm | 1220x2440mm | Fire-resistant cores |

| Metalight Solutions | 65-140 | 1.6-25.4mm | 1250x2500mm | Perforated venting options |

| Alcore Industrial | 50-120 | 4.8-16mm | 1500x3000mm | Pre-bonded adhesive systems |

Manufacturing tolerances vary critically between producers, with top-tier suppliers maintaining ±0.05mm dimensional consistency across full production runs. Certification requirements dictate production standards, with AS9100 accreditation necessary for aerospace applications while marine specifications demand specific Lloyd's Register certifications. Production capability directly affects lead times - standardized cores ship in 2-3 weeks versus 4-6 weeks for customized configurations.

Custom Solutions for Industry Requirements

Material customization includes variable permeability configurations ranging from sealed to highly ventilated structures with channel frequencies from 3 to 45 vents per square meter. Non-standard thickness options span 5-200mm with specialized adhesive systems engineered for specific environmental exposure. Thermal management designs incorporate strategically placed insulating composite layers that reduce thermal bridging by 65% while maintaining structural rigidity. Customizable surface characteristics accommodate bonding requirements with specific surface roughness measurements from 3.2 to 12.5 microns. Sound attenuation enhancements add specialized linings that increase STC ratings by 8-12 points without compromising aerodynamic efficiency.

Aerospace and Transportation Applications

Airbus A350 components demonstrate performance benchmarks with interior panel systems weighing 35% less than traditional designs while meeting stringent FAA flammability standards. High-speed rail applications reduce overall train weight by 18 metric tons per 8-car set, decreasing energy consumption by approximately 12%. Drone manufacturers achieve flight duration increases of over 20% through 5052 honeycomb structural components. Electric vehicle battery enclosures leverage the material's impact resistance properties with crush zones absorbing 150kJ/m³ during collision simulations while providing thermal runway mitigation through integrated venting pathways. All applications demonstrate vibration damping qualities with resonant frequencies reduced by 40-60Hz in comparative testing.

Architectural and Marine Implementation Cases

The Shanghai Exhibition Center renovation used extruded aluminum honeycomb panels for both exterior cladding and interior feature walls, achieving an 82% material reduction versus solid aluminum alternatives while maintaining required deflection tolerances under wind loads. Marine applications at the San Diego Yacht Club used vented honeycomb core panels to construct floating platforms that resist 3m wave impacts without deformation. Stadium retractable roof projects in Qatar implemented specialized corrosion-resistant versions that withstand salt air exposure while reducing roof mechanism weight by 32 metric tons. Architectural installations consistently demonstrate reduced deflection rates – measured at under 0.1% across spans up to 20 meters – alongside temperature stability maintaining panel flatness within ±0.3mm across operating temperatures from -40°C to +82°C.

Why 5052 Aluminum Honeycomb Core Remains the Material of Choice

Environmental factors increasingly influence material selection, where 5052 aluminum honeycomb core shows clear advantages in lifecycle assessments. Production consumes 60% less energy than equivalent polymer matrix composites, while the material's recyclability achieves 95% reclaim rates. Performance testing confirms that fire-rated versions maintain structural integrity at 500°C for 45 minutes – exceeding most commercial building requirements. Cost analysis across 15-year service periods shows installed cost reductions of 22-27% compared to alternative solutions when calculating structural value per unit mass. Installation techniques developed since 2010 have reduced labor requirements by nearly 40% through precision-engineered joining systems that have decreased assembly time for complex structures.

(5052 aluminum honeycomb core)

FAQS on 5052 aluminum honeycomb core

Q: What is 5052 aluminum honeycomb core?

A: 5052 aluminum honeycomb core is a lightweight structural material made from corrosion-resistant 5052 alloy sheets formed into hexagonal cells. It offers high strength-to-weight ratios and excellent impact resistance. This core is widely used in aerospace and transportation applications.

Q: How does extruded aluminum honeycomb differ from standard honeycomb?

A: Extruded aluminum honeycomb is manufactured through continuous pressing, creating more uniform cell structures than traditional expansion methods. This process enhances dimensional stability and surface flatness. It’s ideal for architectural panels and precision industrial components.

Q: Where would vented aluminum honeycomb be required?

A: Vented aluminum honeycomb features perforations enabling airflow or fluid passage while maintaining structural rigidity. It’s essential in HVAC systems, acoustic enclosures, and EMI/RF shielding applications. The venting prevents pressure buildup and improves thermal/acoustic performance.

Q: What are the load-bearing benefits of 5052 aluminum honeycomb core?

A: The hexagonal cell geometry of 5052 honeycomb distributes compressive and shear forces efficiently across all axes. Its design withstands 3-5 times more pressure than equivalent solid aluminum while weighing significantly less. This makes it perfect for flooring, partitions, and vehicle chassis.

Q: Can extruded aluminum honeycomb handle thermal stresses?

A: Yes, extruded aluminum honeycomb’s continuous grain structure provides superior thermal conductivity and stress dissipation. The homogeneous cells minimize thermal expansion mismatches in composite sandwich panels. Consequently, it performs reliably in engine components and cryogenic environments.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

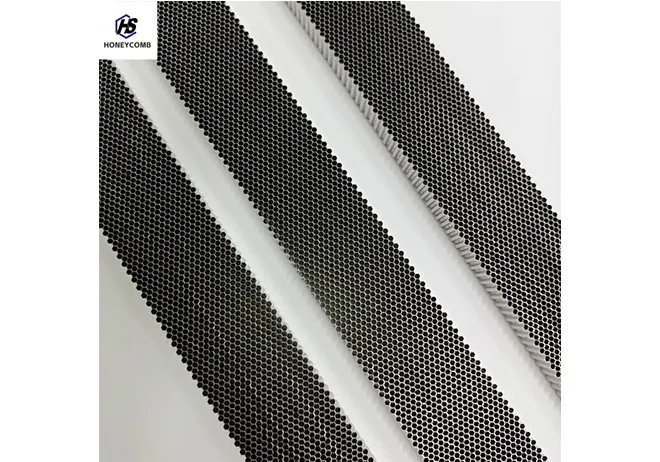

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025