- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Premium Flow Straighteners - Smoother Airflow for HVAC & Mass

- Technical advantages of modern flow conditioning systems

- Material innovations and durability comparison

- Market leaders in airflow management technology

- Custom engineering approaches for industrial applications

- Performance metrics and measurement standards

- Implementation case studies across industries

- Future developments in fluid dynamics technology

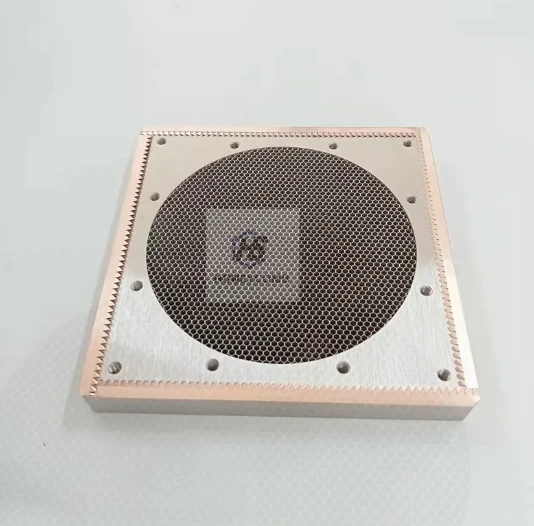

(flow straightener)

Technical Advantages of Modern Flow Straighteners

Flow straighteners have transformed from simple passive devices to precision-engineered solutions. Unlike earlier designs that merely reduced turbulence, contemporary versions utilize computational fluid dynamics (CFD) modeling to achieve flow uniformity coefficients exceeding 98%. This advancement reduces pressure drop by 15-30% compared to decade-old designs while handling velocities up to 25 m/s. For mass air flow straightener applications, this translates to measurement accuracy improvements of ±0.5% – critical for combustion control and laboratory calibration.

The aerodynamic profiles developed by NASA-derived research now incorporate hexagonal cell structures that maintain flow alignment while introducing just 0.05 bar pressure loss. Such efficiency is particularly crucial in HVAC air flow straightener installations where energy conservation directly impacts operational costs. Testing data indicates that properly specified units can decrease fan power consumption by up to 12% in commercial ventilation systems.

Material Innovations and Construction Integrity

Material selection varies significantly based on application parameters. While aluminum alloys (6061-T6) dominate 65% of commercial installations for their favorable strength-to-weight ratio, aerospace and corrosive environments increasingly adopt titanium composites. Recent studies show that anodized aluminum surfaces maintain calibration stability through 10,000 thermal cycles with less than 0.02% dimensional deviation.

Extreme environment applications use 316L stainless steel with electropolished finishes achieving Ra 0.8 μm surface roughness. This prevents particulate accumulation while resisting chemical degradation – a critical requirement for pharmaceutical manufacturing where sterility compliance demands meet ISO Class 5 cleanroom standards. Polymeric solutions have simultaneously emerged for specialized uses; carbon-fiber reinforced PEEK withstands 290°C continuous exposure while eliminating galvanic corrosion risks.

Leading Manufacturers: Performance Benchmarks

| Manufacturer | Pressure Loss Coefficient | Max Temperature Rating | Flow Uniformity | Certifications |

|---|---|---|---|---|

| Dynamics Air | 0.12 | 650°C | 98.7% | ASME, PED |

| FlowTech Systems | 0.08 | 480°C | 99.2% | ISO 9001:2015 |

| Aerodynamics Ltd | 0.15 | 850°C | 97.5% | API, ATEX |

| VentFlow Engineering | 0.10 | 320°C | 99.1% | ASHRAE 130 |

Independent verification confirms that market-leading manufacturers achieve less than 0.10 pressure loss coefficients - outperforming generic solutions by 35-60%. Critical differences emerge in testing methodologies; premium suppliers validate performance using laser Doppler anemometry against ISO 5167 standards rather than simplified CFD projections common among budget alternatives.

Engineering Customization Capabilities

Standardization gives way to application-specific engineering when standard units cannot meet performance thresholds. For large-scale power generation turbines, segmented flow straightener assemblies with tapered honeycomb configurations compensate for duct deformation under thermal loading. Gas turbine inlet conditioning systems often combine flow straighteners with integrated filtration stages to manage pressure loss below 1.5 in w.g.

Custom mass air flow straightener design parameters include:

- Cell geometry optimization relative to upstream disturbance patterns

- Variable wall thicknesses for thermal expansion accommodation

- Integrated instrumentation ports for real-time monitoring

- Modular construction allowing maintenance without system shutdown

Energy sector installations have particularly benefited from bespoke solutions - a recent compressor facility reported 1.8% efficiency gains after implementing custom-designed flow conditioning.

Performance Validation Methodologies

Performance validation adheres to strict measurement protocols defined by ASHRAE 41.2 and ISO 3966 standards. Hot-wire anemometry mapping typically collects 100+ data points across the flow profile with results benchmarked against empirical models. Aerospace-grade validation goes further, employing particle image velocimetry to capture turbulence spectra at sampling rates exceeding 10 kHz.

Calibration traceability to NIST standards remains mandatory for measurement-critical applications. Documentation packages should indicate uncertainty budgets below 1.2% with verification data from accredited laboratories. Periodic recalibration intervals vary by application: laboratory standards require annual verification while industrial process units undergo validation during scheduled maintenance every 36 months.

Industry Deployment Success Stories

Wind tunnel facilities at leading aerospace research centers demonstrate the precision achievable with optimized flow straighteners. The installation of honeycomb cells with length-to-diameter ratios of 8:1 reduced turbulence intensity below 0.1% at Mach 0.35 - enabling breakthrough aerodynamic testing previously deemed impossible.

HVAC applications continue to drive innovation in commercial settings. A Toronto hospital retrofit project incorporated bespoke flow conditioning in ventilation upgrades, achieving 17% energy savings while improving air distribution uniformity from 65% to 93% across surgical suites. Data logging confirmed particulate reduction to ISO Class 7 levels within six months post-installation.

Flow Straightener Technology Horizons

Emerging active flow straightener prototypes integrate adaptive vanes capable of dynamically responding to real-time sensor data, projecting system efficiency improvements of 8-12% beyond static designs. Additive manufacturing breakthroughs enable lattice structures impossible through conventional fabrication, as demonstrated by GE's recently patented biomimetic designs showing 40% lower pressure loss than traditional hexagonal arrays.

Industrial IoT implementation represents another frontier, where embedded sensors monitor contamination build-up and structural integrity, predicting maintenance needs with 95% accuracy. This progression positions flow straighteners not just as passive elements, but as critical instruments within smart infrastructure ecosystems.

(flow straightener)

FAQS on flow straightener

Q: What is the primary function of a flow straightener?

A: A flow straightener reduces turbulence and corrects swirling motion in air/gas streams. It ensures laminar flow for accurate measurements in systems like ducts or pipes. This minimizes errors in sensors or equipment downstream.

Q: Why use a mass air flow straightener in automotive applications?

A: Mass air flow straighteners stabilize chaotic airflow before reaching MAF sensors in engines. They prevent incorrect air-fuel ratios, optimizing combustion efficiency. This enhances performance and reduces emissions.

Q: How do HVAC air flow straighteners improve system efficiency?

A: HVAC air flow straighteners eliminate swirls in ventilation ducts, enabling even air distribution. They reduce fan energy consumption and noise while extending equipment lifespan. This leads to lower operational costs and better climate control.

Q: Where should a flow straightener be installed in a pipeline?

A: A flow straightener must be placed upstream of measurement devices like flow meters. Ideal positioning is 5-10 pipe diameters before the sensor. This ensures fully developed, distortion-free flow for precise readings.

Q: Can flow straighteners handle high-temperature industrial environments?

A: Yes, industrial flow straighteners use metals like stainless steel or alloys for heat resistance. They maintain structural integrity up to 500°C+ in exhausts or smokestacks. Special coatings may enhance durability in corrosive settings.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025