- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 07:55

Back to list

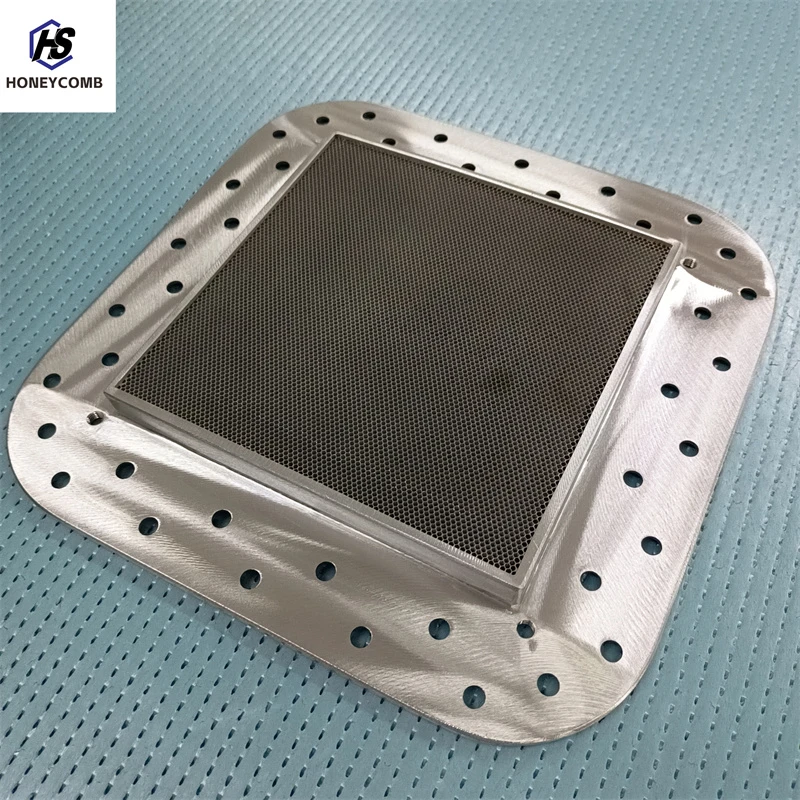

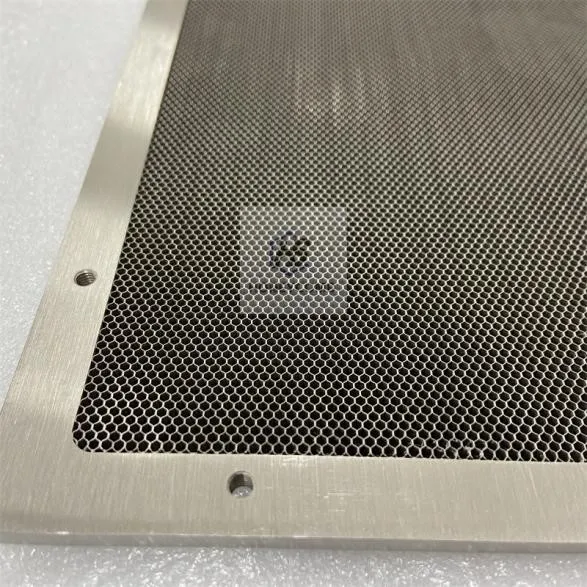

5052 aluminium bikakekärna

Exploring the Intricacies of 5052 Aluminium Bikakekärna The Core of Modern Innovation

Ensuring the trustworthiness of 5052 aluminium bikakekärna means further investigating its composition and manufacturing techniques. Producers of this alloy are committed to rigorous quality control measures, adhering to international standards that guarantee performance consistency. Users can confidently opt for the material, knowing that each product cycle is monitored and evaluated for compliance with industry benchmarks. Among firsthand experiences, manufacturers recount the efficiency in welding applications. The alloy's weldability is noted for creating seamless joints which enhance the collective strength of the finished product. This attribute is critical in sectors where reliable joints can mean the difference between structural success and catastrophic failure. In practical application, 5052 aluminium bikakekärna’s lightweight nature allows for increased fuel efficiencies in transportation. For electric vehicles, this reduction in weight translates into extended battery life and improved range, aligning perfectly with the global shift towards greener technologies. Furthermore, for the shipping industry, the diminished weight supports greater payload capacities without sacrificing vessel performance. While the 5052 aluminium bikakekärna continues to prove its value across diverse fields, innovation within the alloy itself remains active. Researchers and engineers are tirelessly experimenting with minor compositional adjustments to further enhance its capabilities, such as increased thermal management for electronic housings or advanced anodizing techniques for improved surface finishes. In conclusion, the 5052 aluminium bikakekärna is a testament to how meticulous engineering and focused research can culminate in materials that redefine industry standards. While its benefits are myriad, the ongoing exploration of its capabilities ensures that it will remain a cornerstone of design and manufacturing, encouraging both sustainability and performance across various sectors. As industries embrace this alloy, its continued evolution will not only support immediate needs but also anticipate future applications in uncharted territories of innovation.

Ensuring the trustworthiness of 5052 aluminium bikakekärna means further investigating its composition and manufacturing techniques. Producers of this alloy are committed to rigorous quality control measures, adhering to international standards that guarantee performance consistency. Users can confidently opt for the material, knowing that each product cycle is monitored and evaluated for compliance with industry benchmarks. Among firsthand experiences, manufacturers recount the efficiency in welding applications. The alloy's weldability is noted for creating seamless joints which enhance the collective strength of the finished product. This attribute is critical in sectors where reliable joints can mean the difference between structural success and catastrophic failure. In practical application, 5052 aluminium bikakekärna’s lightweight nature allows for increased fuel efficiencies in transportation. For electric vehicles, this reduction in weight translates into extended battery life and improved range, aligning perfectly with the global shift towards greener technologies. Furthermore, for the shipping industry, the diminished weight supports greater payload capacities without sacrificing vessel performance. While the 5052 aluminium bikakekärna continues to prove its value across diverse fields, innovation within the alloy itself remains active. Researchers and engineers are tirelessly experimenting with minor compositional adjustments to further enhance its capabilities, such as increased thermal management for electronic housings or advanced anodizing techniques for improved surface finishes. In conclusion, the 5052 aluminium bikakekärna is a testament to how meticulous engineering and focused research can culminate in materials that redefine industry standards. While its benefits are myriad, the ongoing exploration of its capabilities ensures that it will remain a cornerstone of design and manufacturing, encouraging both sustainability and performance across various sectors. As industries embrace this alloy, its continued evolution will not only support immediate needs but also anticipate future applications in uncharted territories of innovation.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025