- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 17:23

Back to list

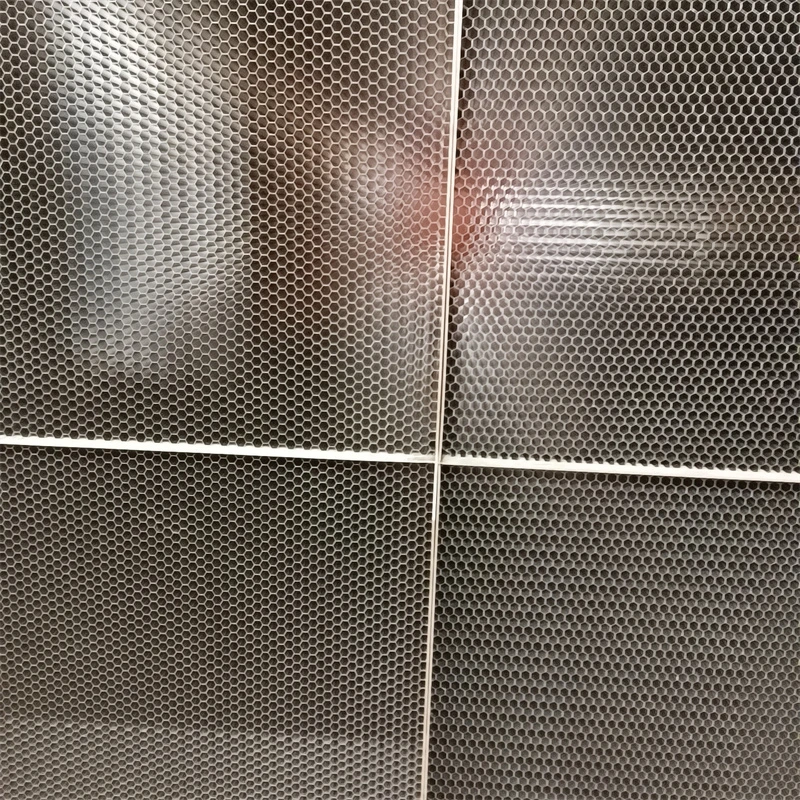

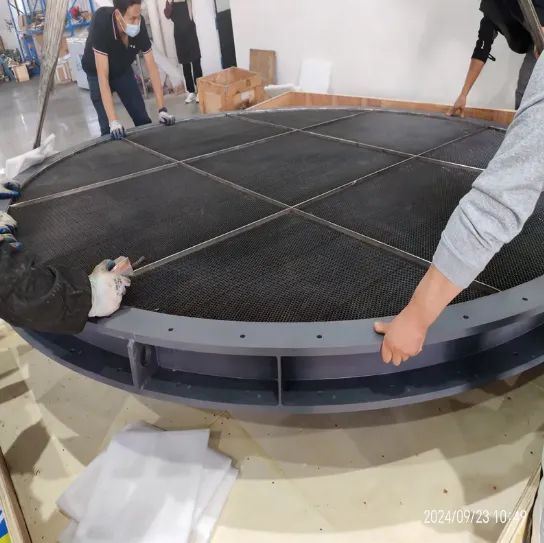

5052 croí honeycomb alúmanaim

The 5052 croí honeycomb aluminum material represents a pinnacle in technological innovation in materials engineering. Engineers and designers are constantly looking for materials that balance strength, weight, and durability, and this product emerges as a strong candidate in various industries, including aerospace, automotive, and construction.

The authority of 5052 croí honeycomb aluminum in its field is backed by rigorous scientific testing and validation. Multiple studies have confirmed its resilience and adaptability, especially under mechanical stresses. Its adoption by leading aerospace companies for components like aircraft floors and bulkheads underscores its reliability. The aerospace sector, with its stringent safety and efficacy standards, trusts this material because it meets demanding performance criteria without failure, thus ensuring passenger and crew safety. Trustworthiness in any material is essential for its widespread adoption, and 5052 croí honeycomb aluminum has earned its place through consistent performance and compliance with international standards. Manufacturing processes are closely monitored, and the final product is compliant with various industry-specific quality certifications, including ISO and ASTM standards. Moreover, it is environmentally friendly, as aluminum is one of the most recyclable materials, allowing industries to minimize their carbon footprint while maintaining product quality. In conclusion, 5052 croí honeycomb aluminum stands out not just as a material but as a pivotal innovation offering a harmonious blend of experience-backed performance, specialized expertise, authority in its reliability confirmed by top-tier industries, and a trustworthy profile supported by global standards and eco-friendly credentials. Its application across diverse sectors highlights its versatility and adaptability, making it a preferred material for forward-thinking engineers and designers.

The authority of 5052 croí honeycomb aluminum in its field is backed by rigorous scientific testing and validation. Multiple studies have confirmed its resilience and adaptability, especially under mechanical stresses. Its adoption by leading aerospace companies for components like aircraft floors and bulkheads underscores its reliability. The aerospace sector, with its stringent safety and efficacy standards, trusts this material because it meets demanding performance criteria without failure, thus ensuring passenger and crew safety. Trustworthiness in any material is essential for its widespread adoption, and 5052 croí honeycomb aluminum has earned its place through consistent performance and compliance with international standards. Manufacturing processes are closely monitored, and the final product is compliant with various industry-specific quality certifications, including ISO and ASTM standards. Moreover, it is environmentally friendly, as aluminum is one of the most recyclable materials, allowing industries to minimize their carbon footprint while maintaining product quality. In conclusion, 5052 croí honeycomb aluminum stands out not just as a material but as a pivotal innovation offering a harmonious blend of experience-backed performance, specialized expertise, authority in its reliability confirmed by top-tier industries, and a trustworthy profile supported by global standards and eco-friendly credentials. Its application across diverse sectors highlights its versatility and adaptability, making it a preferred material for forward-thinking engineers and designers.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025