- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 17:50

Back to list

struchtúr honeycomb alúmanaim

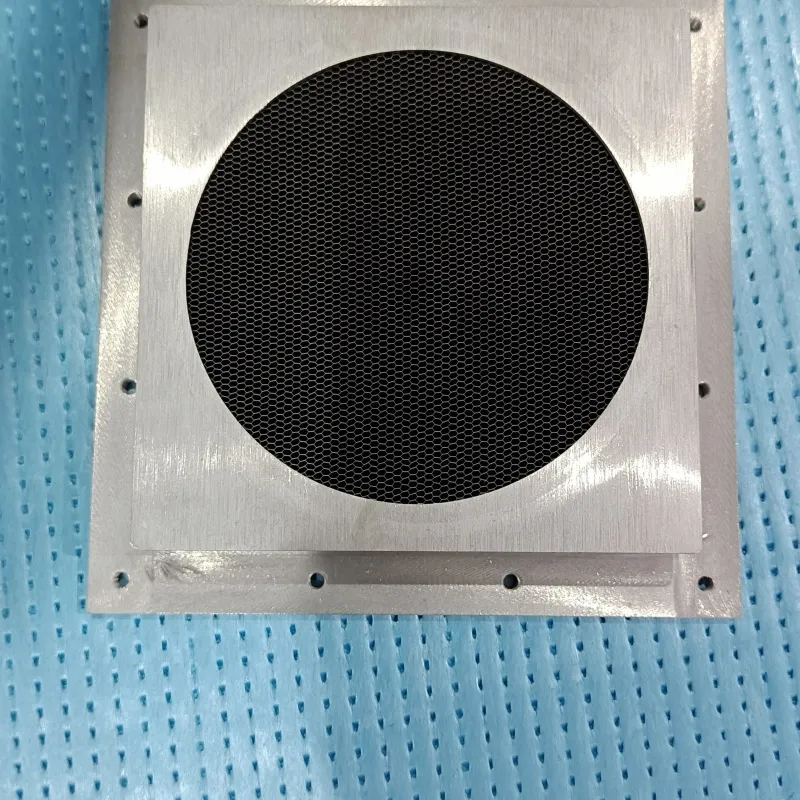

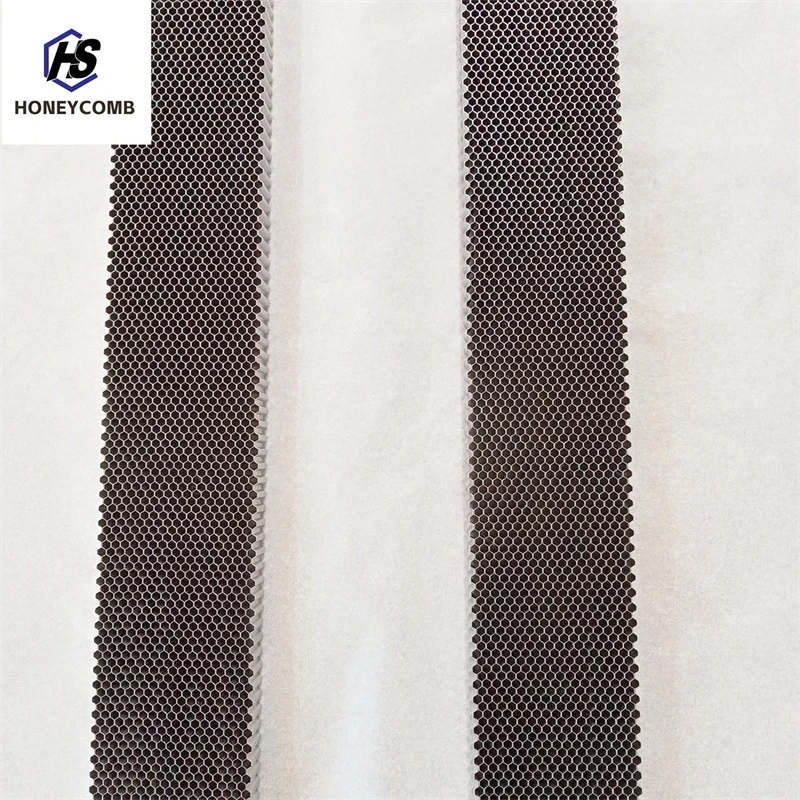

Aluminum honeycomb structures are architectural and engineering marvels that encapsulate a unique combination of strength, lightweight properties, and versatility. These structures are at the forefront of innovative design and engineering, offering significant benefits across a wide range of industries, from aerospace to construction. As an experienced SEO specialist, let's delve into the nuanced aspects of aluminum honeycomb structures that enhance their appeal and utility, emphasizing their experiential advantages, professional relevance, authority in material science, and the trust they foster among engineers and architects.

The authority of aluminum honeycomb structures is grounded in their extensive application and validation across various domains. Institutions and large-scale engineering firms frequently cite these structures in technical publications and case studies, showcasing their successful use in landmark projects. For example, these panels have been employed in the construction of high-speed trains, where their vibration-dampening properties enhance passenger comfort by reducing noise and improving cabin environment stability. Such authoritative case uses provide compelling evidence of their capabilities, encouraging further adoption in innovative ways. Trust in aluminum honeycomb structures among professionals and clientele is built upon a solid foundation of proven performance and reliable outcomes. Manufacturers often subject these panels to rigorous compliance testing, meeting stringent certifications and safety standards required by both national and international bodies. This rigorous vetting process instills confidence in engineers and decision-makers, reinforcing the trust that these structures will perform as required across applications. Furthermore, long-term observational studies and user testimonials frequently highlight their resilience and longevity, promoting an enduring trust in their use for future projects. In conclusion, aluminum honeycomb structures represent a pinnacle of material science and engineering, demonstrating unparalleled advantages across a spectrum of applications. Whether admired for their structural performance, backed by professional expertise, or validated through authoritative use cases, these remarkable structures symbolize a commitment to excellence that aligns with contemporary demands for efficiency and sustainability. The trust they engender among professionals ensures they remain a top choice for any project aspiring to blend sophistication with technical prowess.

The authority of aluminum honeycomb structures is grounded in their extensive application and validation across various domains. Institutions and large-scale engineering firms frequently cite these structures in technical publications and case studies, showcasing their successful use in landmark projects. For example, these panels have been employed in the construction of high-speed trains, where their vibration-dampening properties enhance passenger comfort by reducing noise and improving cabin environment stability. Such authoritative case uses provide compelling evidence of their capabilities, encouraging further adoption in innovative ways. Trust in aluminum honeycomb structures among professionals and clientele is built upon a solid foundation of proven performance and reliable outcomes. Manufacturers often subject these panels to rigorous compliance testing, meeting stringent certifications and safety standards required by both national and international bodies. This rigorous vetting process instills confidence in engineers and decision-makers, reinforcing the trust that these structures will perform as required across applications. Furthermore, long-term observational studies and user testimonials frequently highlight their resilience and longevity, promoting an enduring trust in their use for future projects. In conclusion, aluminum honeycomb structures represent a pinnacle of material science and engineering, demonstrating unparalleled advantages across a spectrum of applications. Whether admired for their structural performance, backed by professional expertise, or validated through authoritative use cases, these remarkable structures symbolize a commitment to excellence that aligns with contemporary demands for efficiency and sustainability. The trust they engender among professionals ensures they remain a top choice for any project aspiring to blend sophistication with technical prowess.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025