- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 18:11

Back to list

cíor meala alúmanaim easbhrúite

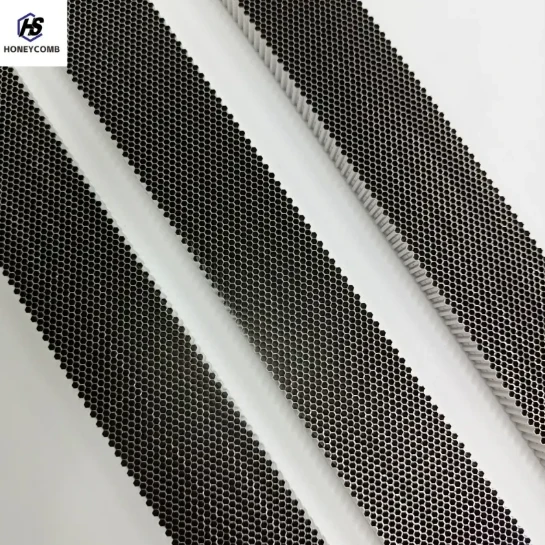

Aluminum extruded honeycomb panels have captured the attention of architects, engineers, and manufacturers due to their impressive performance characteristics and versatility. These panels, known as 'cíor meala alúmanaim easbhrúite' in Irish, are distinguished by their lightweight nature, high strength, and excellent energy absorption properties. Industries ranging from aerospace to infrastructure are adopting this innovative material, guided by experience and expertise from years of research and practical applications.

The manufacturing process of aluminum extruded honeycomb panels also underscores their trustworthiness. Utilizing high-quality aluminum alloys combined with advanced extrusion techniques, manufacturers ensure uniformity and durability. The extrusion process allows for precise control over cell size and panel thickness, providing consistency that is essential for quality assurance in high-stakes applications. Manufacturers with ISO certifications reinforce trust levels by adhering to stringent quality controls, ensuring each panel meets global standards. Industry experts underline the panels' customizability as another point of authority. Offered in various finishes and coatings, aluminum extruded honeycomb panels can be tailored to meet specific environmental requirements, including resistance to UV exposure, chemical interactions, and corrosive elements. This adaptability makes them ideal for diverse climates and operational conditions, from beachfront constructions to industrial complexes. Throughout these applications, real-world experience plays a crucial role in demonstrating the panels' capabilities. Engineers and architects frequently share project results and performance metrics at conferences and in academic journals, contributing to an ever-growing body of knowledge. This shared expertise helps to continuously refine the application strategies and enhances trust in the material. Aluminum extruded honeycomb panels, therefore, represent a fusion of innovative engineering and practical application, offering a compelling solution across varied fields. With their combination of strength, light weight, and eco-friendliness, they hold significant promise for future advancements in material science and design. As industries globally seek sustainable and high-performance materials, these panels are poised to lead the way, their trajectory buoyed by robust endorsements from authorities in engineering excellence and sustainable practices.

The manufacturing process of aluminum extruded honeycomb panels also underscores their trustworthiness. Utilizing high-quality aluminum alloys combined with advanced extrusion techniques, manufacturers ensure uniformity and durability. The extrusion process allows for precise control over cell size and panel thickness, providing consistency that is essential for quality assurance in high-stakes applications. Manufacturers with ISO certifications reinforce trust levels by adhering to stringent quality controls, ensuring each panel meets global standards. Industry experts underline the panels' customizability as another point of authority. Offered in various finishes and coatings, aluminum extruded honeycomb panels can be tailored to meet specific environmental requirements, including resistance to UV exposure, chemical interactions, and corrosive elements. This adaptability makes them ideal for diverse climates and operational conditions, from beachfront constructions to industrial complexes. Throughout these applications, real-world experience plays a crucial role in demonstrating the panels' capabilities. Engineers and architects frequently share project results and performance metrics at conferences and in academic journals, contributing to an ever-growing body of knowledge. This shared expertise helps to continuously refine the application strategies and enhances trust in the material. Aluminum extruded honeycomb panels, therefore, represent a fusion of innovative engineering and practical application, offering a compelling solution across varied fields. With their combination of strength, light weight, and eco-friendliness, they hold significant promise for future advancements in material science and design. As industries globally seek sustainable and high-performance materials, these panels are poised to lead the way, their trajectory buoyed by robust endorsements from authorities in engineering excellence and sustainable practices.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025