- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 05:20

Back to list

أختام قرص العسل

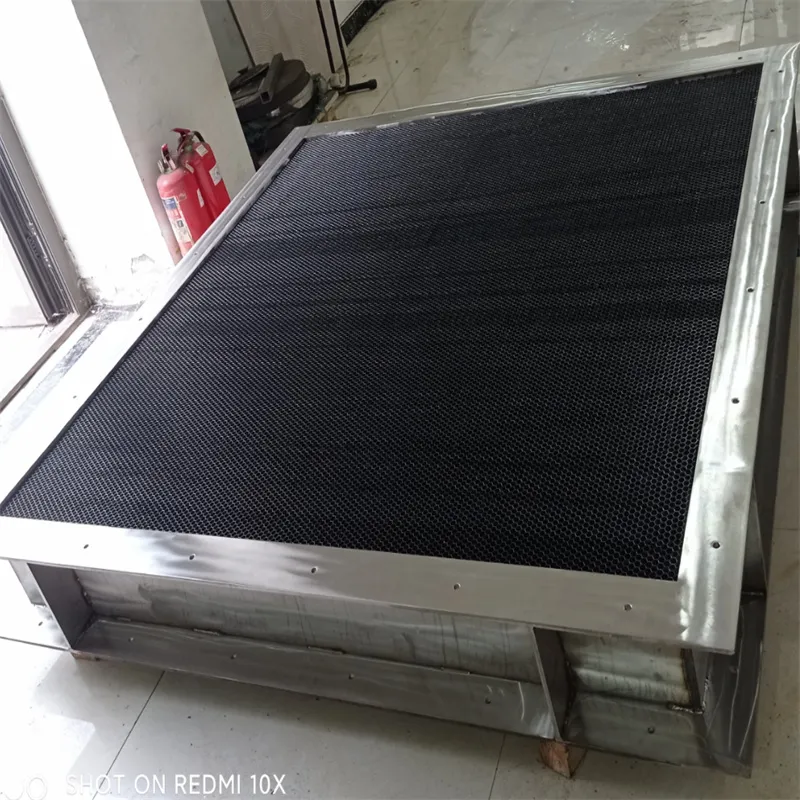

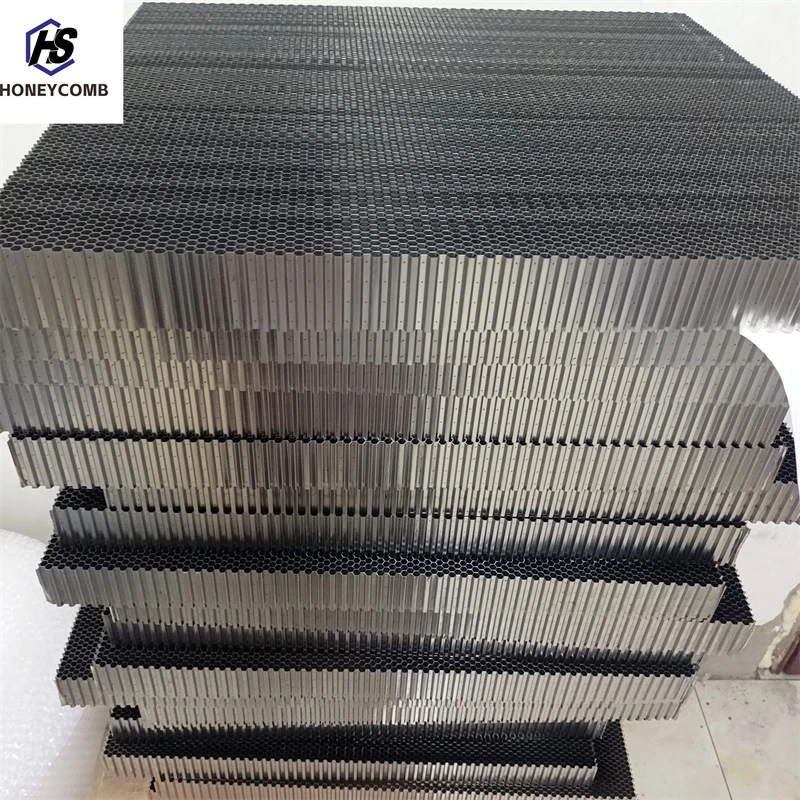

Honeycomb seals, a term that often conjures images of nature's intricate designs, represent a leap in the field of industrial sealing technology. These seals are primarily known for their ability to reduce leakage in various machinery, and their design takes inspiration from the natural geometry of honeycombs, offering a blend of efficiency, durability, and precise engineering.

Trustworthiness in the Field The adoption of honeycomb seals across industries is a testament to their trustworthiness. Engineers and procurement specialists continually recommend these seals because of their proven track records in enhancing machinery performance. Before they hit the market, each batch of honeycomb seals undergoes rigorous testing, meeting high industry standards for safety and efficiency. This ensures a consistent level of quality and reliability, making them a go-to choice for maintenance teams looking to optimize performance. Furthermore, manufacturers provide extensive documentation to support the implementation and maintenance of honeycomb seals. This includes detailed guides on installation processes, maintenance practices, and troubleshooting tips. This transparency and support further bolster trust in their use, as professionals know they can rely on comprehensive guidance for optimal performance. Innovation at the Heart of Honeycomb Seals While the basic design of honeycomb seals is inspired by nature, the ongoing innovations in materials and design illustrate a commitment to continuous improvement. Advances in computational design techniques and material compositions are allowing industrialists to customize solutions tailored to specific applications, bringing about better energy efficiency and reduced operational costs. A Revolutionary Perspective in Industrial Seals Honeycomb seals signify a revolutionary shift in the approach to minimizing leakage and maximizing efficiency in high-stakes environments. Their unique design and material composition stand out as examples of human ingenuity, blending scientific understanding with practical application. In summary, honeycomb seals are not just a product but a critical component in the ongoing quest to improve machinery efficiency and reliability. They embody a synthesis of experience, expertise, and trustworthiness, essentials in any high-stake industrial application. With their increasing adoption and continued innovation, these seals are set to remain an integral part of sophisticated machinery for years to come. By providing enhanced sealing solutions, they offer industries a reliable option to push the boundaries of performance and efficiency.

Trustworthiness in the Field The adoption of honeycomb seals across industries is a testament to their trustworthiness. Engineers and procurement specialists continually recommend these seals because of their proven track records in enhancing machinery performance. Before they hit the market, each batch of honeycomb seals undergoes rigorous testing, meeting high industry standards for safety and efficiency. This ensures a consistent level of quality and reliability, making them a go-to choice for maintenance teams looking to optimize performance. Furthermore, manufacturers provide extensive documentation to support the implementation and maintenance of honeycomb seals. This includes detailed guides on installation processes, maintenance practices, and troubleshooting tips. This transparency and support further bolster trust in their use, as professionals know they can rely on comprehensive guidance for optimal performance. Innovation at the Heart of Honeycomb Seals While the basic design of honeycomb seals is inspired by nature, the ongoing innovations in materials and design illustrate a commitment to continuous improvement. Advances in computational design techniques and material compositions are allowing industrialists to customize solutions tailored to specific applications, bringing about better energy efficiency and reduced operational costs. A Revolutionary Perspective in Industrial Seals Honeycomb seals signify a revolutionary shift in the approach to minimizing leakage and maximizing efficiency in high-stakes environments. Their unique design and material composition stand out as examples of human ingenuity, blending scientific understanding with practical application. In summary, honeycomb seals are not just a product but a critical component in the ongoing quest to improve machinery efficiency and reliability. They embody a synthesis of experience, expertise, and trustworthiness, essentials in any high-stake industrial application. With their increasing adoption and continued innovation, these seals are set to remain an integral part of sophisticated machinery for years to come. By providing enhanced sealing solutions, they offer industries a reliable option to push the boundaries of performance and efficiency.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025