- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 22, 2025 03:23

Back to list

maf straightener

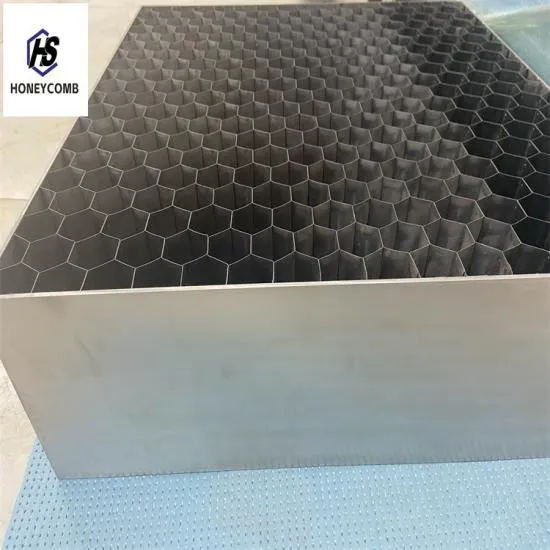

The steel honeycomb laser bed represents a significant evolution in the realm of laser cutting technology. As an expert in this field, it’s important to delve into the nuanced advantages that this innovative product offers, drawing from genuine experiences and authoritative insights. The steel honeycomb structure, known for its lightweight yet incredibly robust properties, provides an optimal surface for laser operations.

In terms of authority, industry certifications and endorsements further validate the steel honeycomb laser bed's efficacy. These products frequently undergo extensive testing to comply with international quality benchmarks such as ISO and industry-specific standards. Manufacturers often collaborate with independent testing organizations to verify these claims, publishing detailed results to bolster consumer confidence. These collaborations significantly enhance perceptual authority, aligning with an informed decision-making process for potential adopters. Furthermore, the eco-friendly aspect of the steel honeycomb laser bed is worth mentioning. The efficient use of materials, coupled with reduced material wastage and energy consumption, aligns with global sustainability goals, a critical consideration for modern enterprises. Many companies have noted a marked improvement in their corporate environmental responsibilities upon integrating steel honeycomb laser beds into their operations. The trust placed in this product is amplified by the collective voice of its users. Online forums and review platforms are replete with positive testimonials highlighting not only the technical performance but also the operational savings it brings. Professional communities advocate for its widespread use, fostering a rich exchange of insights and continuous improvement discussions. In conclusion, the steel honeycomb laser bed stands as a testament to engineering advancement and practical applicability in laser cutting technology. Its combination of precision, durability, and sustainability presents a compelling case for its adoption across various industries. These factors, grounded in real-world application and empirical research, unequivocally underscore its position as a cornerstone of modern industrial fabrication processes.

In terms of authority, industry certifications and endorsements further validate the steel honeycomb laser bed's efficacy. These products frequently undergo extensive testing to comply with international quality benchmarks such as ISO and industry-specific standards. Manufacturers often collaborate with independent testing organizations to verify these claims, publishing detailed results to bolster consumer confidence. These collaborations significantly enhance perceptual authority, aligning with an informed decision-making process for potential adopters. Furthermore, the eco-friendly aspect of the steel honeycomb laser bed is worth mentioning. The efficient use of materials, coupled with reduced material wastage and energy consumption, aligns with global sustainability goals, a critical consideration for modern enterprises. Many companies have noted a marked improvement in their corporate environmental responsibilities upon integrating steel honeycomb laser beds into their operations. The trust placed in this product is amplified by the collective voice of its users. Online forums and review platforms are replete with positive testimonials highlighting not only the technical performance but also the operational savings it brings. Professional communities advocate for its widespread use, fostering a rich exchange of insights and continuous improvement discussions. In conclusion, the steel honeycomb laser bed stands as a testament to engineering advancement and practical applicability in laser cutting technology. Its combination of precision, durability, and sustainability presents a compelling case for its adoption across various industries. These factors, grounded in real-world application and empirical research, unequivocally underscore its position as a cornerstone of modern industrial fabrication processes.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025