- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 03:06

Back to list

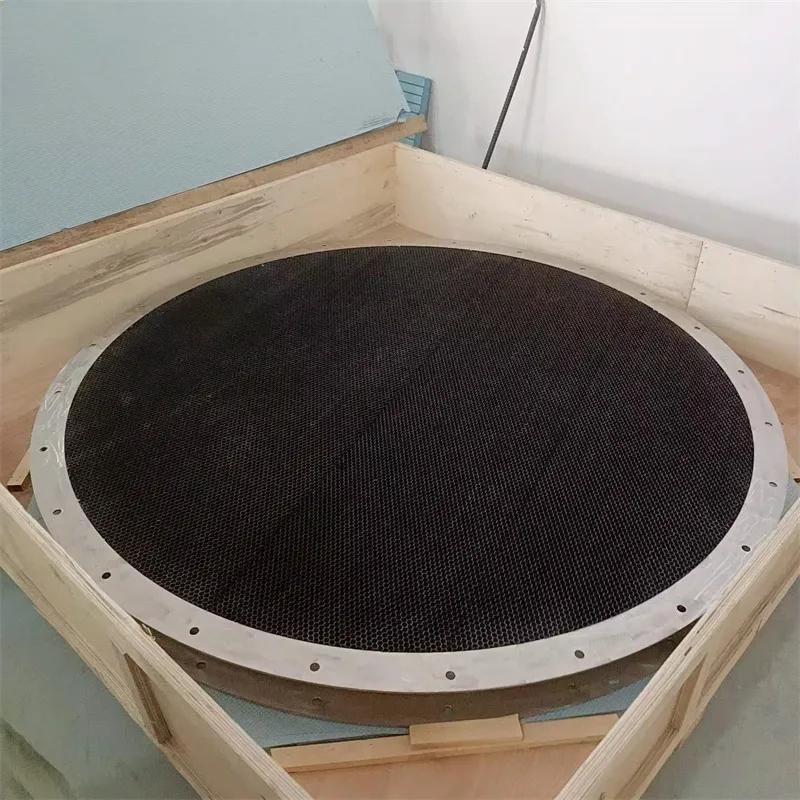

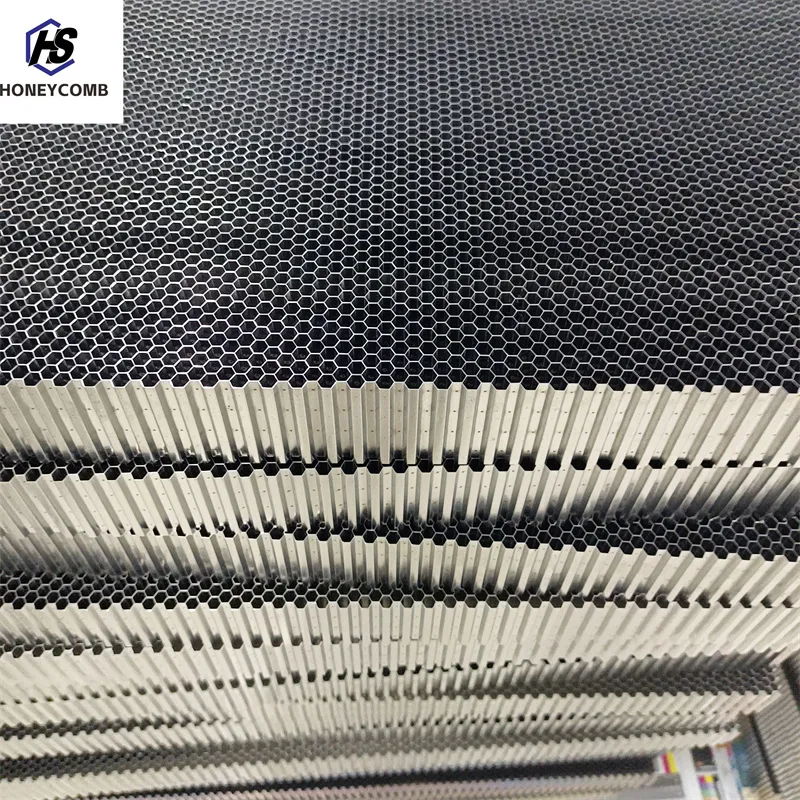

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

Stainless steel honeycomb panels have revolutionized the construction and design industries with their unmatched combination of strength, flexibility, and aesthetic appeal. These panels have become essential elements for both modern architecture and industrial applications.

In terms of installation, stainless steel honeycomb panels offer a straightforward and efficient process. Their lightweight nature significantly reduces the structural load on buildings, often resulting in lower transportation and installation costs compared to traditional materials. This ease of handling also means faster completion times for projects, offering economic benefits and enhancing client satisfaction. Authoritativeness in this domain is demonstrated by the panel's versatility and performance across various prestigious projects. They have been used in iconic structures worldwide, testifying to their quality and effectiveness. When endorsed by professionals and chosen for high-profile projects, these panels stand as a testament to their capabilities and trustworthiness in demanding environments. Trust in stainless steel honeycomb panels derives from their proven track record of enduring performance and the satisfaction of countless architects, engineers, and builders who continue to advocate for their use. Their ability to handle intricate design specifications without compromising on quality ensures repeat usage across industries. Furthermore, the adaptability of stainless steel honeycomb panels extends to numerous industries, enhancing machinery, vehicles, and luxury goods with their strength-to-weight ratio. In the aerospace industry, for instance, they contribute to weight reduction, increasing fuel efficiency and performance in aircraft. In conclusion, stainless steel honeycomb panels offer an unparalleled blend of durability, aesthetic charm, and efficiency that current industries demand. Whether applied in state-of-the-art architecture or critical industrial applications, these panels provide a reliable solution that aligns with the modern priorities of sustainability, innovation, and excellence in design. As technology advances, the material's adaptability confirms its continued relevance and potential for future applications, solidifying its place as a preferred choice among leading professionals globally.

In terms of installation, stainless steel honeycomb panels offer a straightforward and efficient process. Their lightweight nature significantly reduces the structural load on buildings, often resulting in lower transportation and installation costs compared to traditional materials. This ease of handling also means faster completion times for projects, offering economic benefits and enhancing client satisfaction. Authoritativeness in this domain is demonstrated by the panel's versatility and performance across various prestigious projects. They have been used in iconic structures worldwide, testifying to their quality and effectiveness. When endorsed by professionals and chosen for high-profile projects, these panels stand as a testament to their capabilities and trustworthiness in demanding environments. Trust in stainless steel honeycomb panels derives from their proven track record of enduring performance and the satisfaction of countless architects, engineers, and builders who continue to advocate for their use. Their ability to handle intricate design specifications without compromising on quality ensures repeat usage across industries. Furthermore, the adaptability of stainless steel honeycomb panels extends to numerous industries, enhancing machinery, vehicles, and luxury goods with their strength-to-weight ratio. In the aerospace industry, for instance, they contribute to weight reduction, increasing fuel efficiency and performance in aircraft. In conclusion, stainless steel honeycomb panels offer an unparalleled blend of durability, aesthetic charm, and efficiency that current industries demand. Whether applied in state-of-the-art architecture or critical industrial applications, these panels provide a reliable solution that aligns with the modern priorities of sustainability, innovation, and excellence in design. As technology advances, the material's adaptability confirms its continued relevance and potential for future applications, solidifying its place as a preferred choice among leading professionals globally.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025