- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 03:29

Back to list

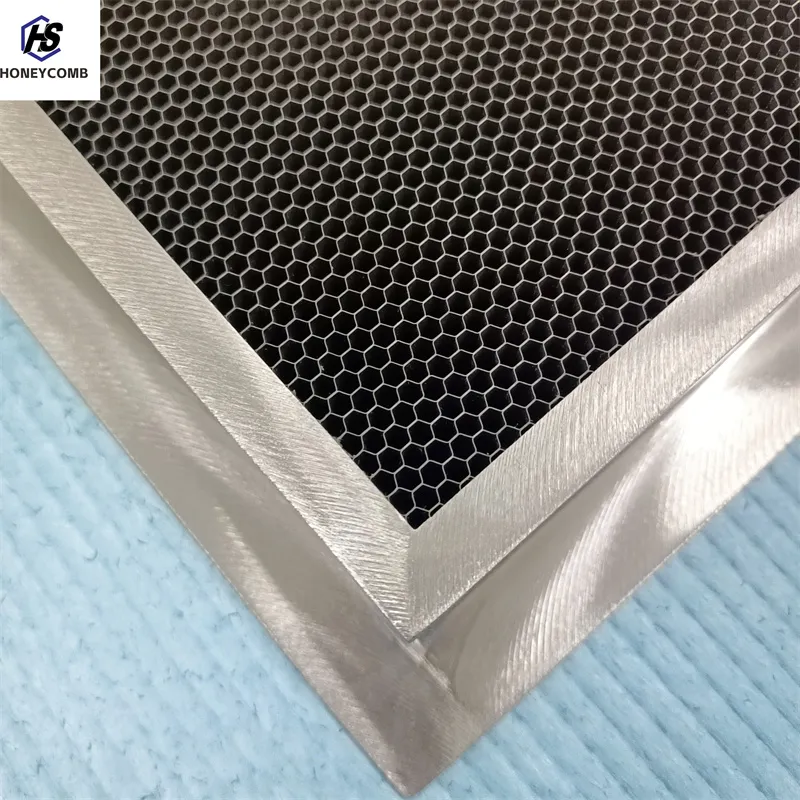

Manufacturer Supply 10mm Stainless Steel 304 Honeycomb for Wind Tunnels Air Flow Testing

In the realm of construction materials, stainless steel honeycomb sandwich panels have emerged as a cutting-edge solution for architects and engineers seeking optimal performance in a variety of applications. These panels, known for their exceptional strength-to-weight ratio, are revolutionizing industries ranging from aerospace to architecture due to their innovative design and unmatched durability.

The acoustic properties of stainless steel honeycomb panels are another attractive feature. They naturally diminish the transmission of sound, making them an excellent choice for structures located in busy urban environments or those requiring noise reduction for privacy or better living conditions. Manufacturers are leveraging advancements in technology to enhance the quality and versatility of these panels. Customization options are vast, allowing manufacturers to meet specific aesthetic and functional requirements. Clients can choose from various finishes, thicknesses, and core materials to suit their project's needs, fostering creativity and innovation in design. Despite their many advantages, efficiency does not come at the expense of sustainability. The materials used in stainless steel honeycomb panels are often recyclable, promoting environmentally-friendly construction practices. This aligns with the growing demand for eco-conscious building solutions, supporting global efforts in sustainable development. Those considering the use of stainless steel honeycomb sandwich panels should consult with industry experts to ensure their choice meets project-specific demands. It is crucial to evaluate parameters such as panel size, structural loads, and environmental conditions to optimize performance and ensure long-term satisfaction. In conclusion, stainless steel honeycomb sandwich panels stand out as a superior product in the construction industry. Their combination of strength, durability, and design flexibility, coupled with sustainable advantages, present a compelling case for their use in a wide range of applications. As industries continue to evolve, these panels are poised to play a major role in the future of building and manufacturing, providing innovative solutions that align with modern demands.

The acoustic properties of stainless steel honeycomb panels are another attractive feature. They naturally diminish the transmission of sound, making them an excellent choice for structures located in busy urban environments or those requiring noise reduction for privacy or better living conditions. Manufacturers are leveraging advancements in technology to enhance the quality and versatility of these panels. Customization options are vast, allowing manufacturers to meet specific aesthetic and functional requirements. Clients can choose from various finishes, thicknesses, and core materials to suit their project's needs, fostering creativity and innovation in design. Despite their many advantages, efficiency does not come at the expense of sustainability. The materials used in stainless steel honeycomb panels are often recyclable, promoting environmentally-friendly construction practices. This aligns with the growing demand for eco-conscious building solutions, supporting global efforts in sustainable development. Those considering the use of stainless steel honeycomb sandwich panels should consult with industry experts to ensure their choice meets project-specific demands. It is crucial to evaluate parameters such as panel size, structural loads, and environmental conditions to optimize performance and ensure long-term satisfaction. In conclusion, stainless steel honeycomb sandwich panels stand out as a superior product in the construction industry. Their combination of strength, durability, and design flexibility, coupled with sustainable advantages, present a compelling case for their use in a wide range of applications. As industries continue to evolve, these panels are poised to play a major role in the future of building and manufacturing, providing innovative solutions that align with modern demands.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025