- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 03:49

Back to list

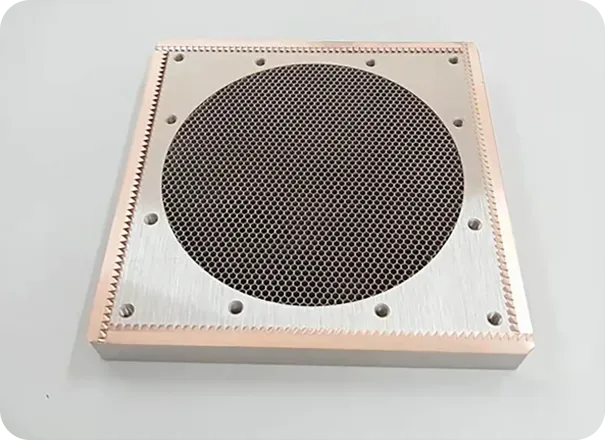

стойка с сотами из нержавеющей стали

In the world of modern design and construction, the inclusion of innovative materials and structures is paramount. Among these, stainless steel honeycomb racks have emerged as a transformative addition across various industries. But what makes these seemingly simple structures stand out in an age of rapid technological advancement?

From a design perspective, the versatility of stainless steel honeycomb racks cannot be overstated. Architects and designers appreciate the modern aesthetic they bring to any project. The sleek, polished appearance of stainless steel complements a wide range of styles, from industrial to minimalist. Furthermore, the adaptability of honeycomb structures allows for custom fabrication, giving designers the flexibility to create bespoke solutions tailored to specific project needs. This adaptability ensures that function and form go hand in hand, enhancing both the practical and visual appeal of any design. The industry’s top experts underscore the importance of precision manufacturing in the construction of these racks. Advanced techniques in fabrication ensure that each component fits seamlessly, a critical factor in achieving the structural benefits of the honeycomb design. The level of precision required in crafting these racks speaks to the expertise involved in their production. Only manufacturers with extensive experience and technical know-how are capable of delivering the high standards expected by industries utilizing these materials. In terms of maintaining trust, clients and industries can find assurance in the statistical data supporting the claims made about stainless steel honeycomb racks. Testimonies from leading companies and case studies demonstrate instances of improved operational efficiency, decreased maintenance costs, and enhanced structural performance. These real-world examples provide a foundation of trust, ensuring stakeholders that their investments in this technology will be sound and fruitful. To summarize, stainless steel honeycomb racks are not just a product of choice for their mechanical strength and aesthetic qualities but are a sophisticated solution that addresses a multitude of industrial needs. Their resilience, versatility, and design benefits render them an indispensable component in future-oriented projects. As industries continue to pursue more efficient, sustainable, and reliable materials, the adoption of stainless steel honeycomb technologies is expected to rise, backed by a legacy of trusted performance and expert craftsmanship.

From a design perspective, the versatility of stainless steel honeycomb racks cannot be overstated. Architects and designers appreciate the modern aesthetic they bring to any project. The sleek, polished appearance of stainless steel complements a wide range of styles, from industrial to minimalist. Furthermore, the adaptability of honeycomb structures allows for custom fabrication, giving designers the flexibility to create bespoke solutions tailored to specific project needs. This adaptability ensures that function and form go hand in hand, enhancing both the practical and visual appeal of any design. The industry’s top experts underscore the importance of precision manufacturing in the construction of these racks. Advanced techniques in fabrication ensure that each component fits seamlessly, a critical factor in achieving the structural benefits of the honeycomb design. The level of precision required in crafting these racks speaks to the expertise involved in their production. Only manufacturers with extensive experience and technical know-how are capable of delivering the high standards expected by industries utilizing these materials. In terms of maintaining trust, clients and industries can find assurance in the statistical data supporting the claims made about stainless steel honeycomb racks. Testimonies from leading companies and case studies demonstrate instances of improved operational efficiency, decreased maintenance costs, and enhanced structural performance. These real-world examples provide a foundation of trust, ensuring stakeholders that their investments in this technology will be sound and fruitful. To summarize, stainless steel honeycomb racks are not just a product of choice for their mechanical strength and aesthetic qualities but are a sophisticated solution that addresses a multitude of industrial needs. Their resilience, versatility, and design benefits render them an indispensable component in future-oriented projects. As industries continue to pursue more efficient, sustainable, and reliable materials, the adoption of stainless steel honeycomb technologies is expected to rise, backed by a legacy of trusted performance and expert craftsmanship.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025