- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 04:00

Back to list

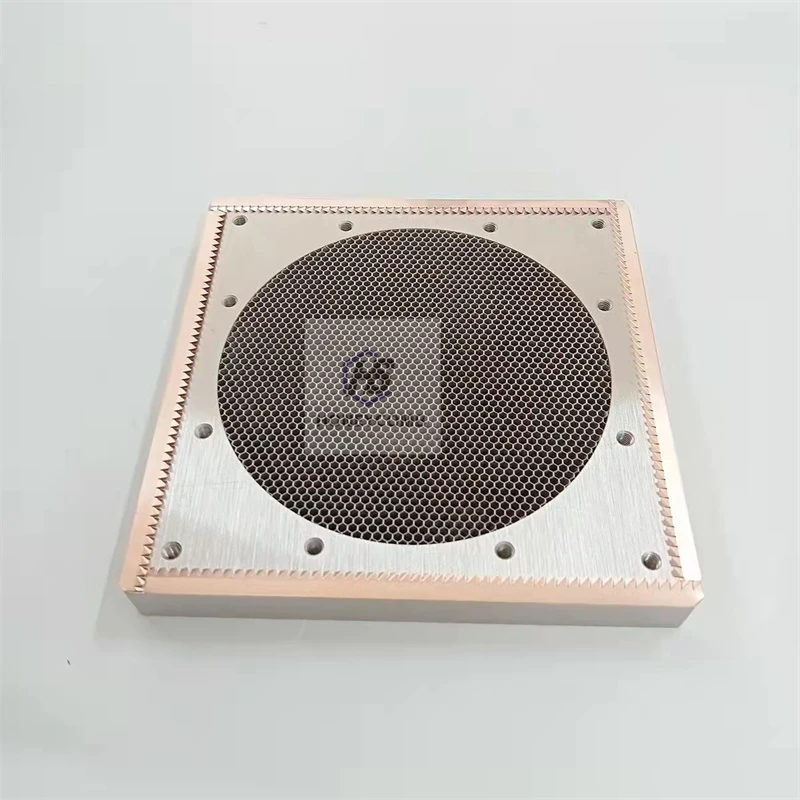

впускное устройство для выпрямления воздуха

The air rectifying intake device has been a revolutionary innovation in the enhancement of airflow management systems, particularly within industrial and mechanical sectors. As industries strive to optimize processes and increase efficiency, the demand for precise and reliable air flow mechanisms has become paramount. This is where the air rectifying intake device, a sophisticated piece of engineering, finds its indispensable place.

Trustworthiness is further validated by numerous customer testimonials and field applications. Companies that have successfully integrated these devices into their operations often become advocates, pointing to tangible savings and performance metrics as evidence. Additionally, manufacturers of these devices are typically certified by leading regulatory bodies, ensuring that each unit meets rigorous quality and safety standards. The practical applications of air rectifying intake devices are vast. In the automotive industry, for instance, they contribute significantly to the cooling efficiency of internal combustion engines, resulting in improved fuel economy and reduced emissions. Meanwhile, in HVAC systems, they optimize the delivery of conditioned air, enhancing comfort while increasing energy savings for residential and commercial buildings. Looking towards the future, ongoing advancements in materials science and computational modeling promise even more refined versions of these devices. There is an ongoing push to utilize lightweight, durable materials that resist corrosion and wear. Furthermore, the integration of smart technology, where sensors embedded within the device can provide real-time data on airflow conditions, stands to revolutionize maintenance practices and operational efficiency. In conclusion, the air rectifying intake device represents a blend of innovation, scientific principles, and practical application. Its capacity to significantly improve airflow dynamics demonstrates its essential role in modern industry. Whether for enhancing machine performance, reducing operational costs, or contributing to environmental sustainability, this device provides a compelling solution for a range of air management challenges. As industries continue to evolve, it is technologies like these that pave the way for future advancements, ensuring that efficiency and reliability remain at the forefront of industrial development.

Trustworthiness is further validated by numerous customer testimonials and field applications. Companies that have successfully integrated these devices into their operations often become advocates, pointing to tangible savings and performance metrics as evidence. Additionally, manufacturers of these devices are typically certified by leading regulatory bodies, ensuring that each unit meets rigorous quality and safety standards. The practical applications of air rectifying intake devices are vast. In the automotive industry, for instance, they contribute significantly to the cooling efficiency of internal combustion engines, resulting in improved fuel economy and reduced emissions. Meanwhile, in HVAC systems, they optimize the delivery of conditioned air, enhancing comfort while increasing energy savings for residential and commercial buildings. Looking towards the future, ongoing advancements in materials science and computational modeling promise even more refined versions of these devices. There is an ongoing push to utilize lightweight, durable materials that resist corrosion and wear. Furthermore, the integration of smart technology, where sensors embedded within the device can provide real-time data on airflow conditions, stands to revolutionize maintenance practices and operational efficiency. In conclusion, the air rectifying intake device represents a blend of innovation, scientific principles, and practical application. Its capacity to significantly improve airflow dynamics demonstrates its essential role in modern industry. Whether for enhancing machine performance, reducing operational costs, or contributing to environmental sustainability, this device provides a compelling solution for a range of air management challenges. As industries continue to evolve, it is technologies like these that pave the way for future advancements, ensuring that efficiency and reliability remain at the forefront of industrial development.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025