- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 04:55

Back to list

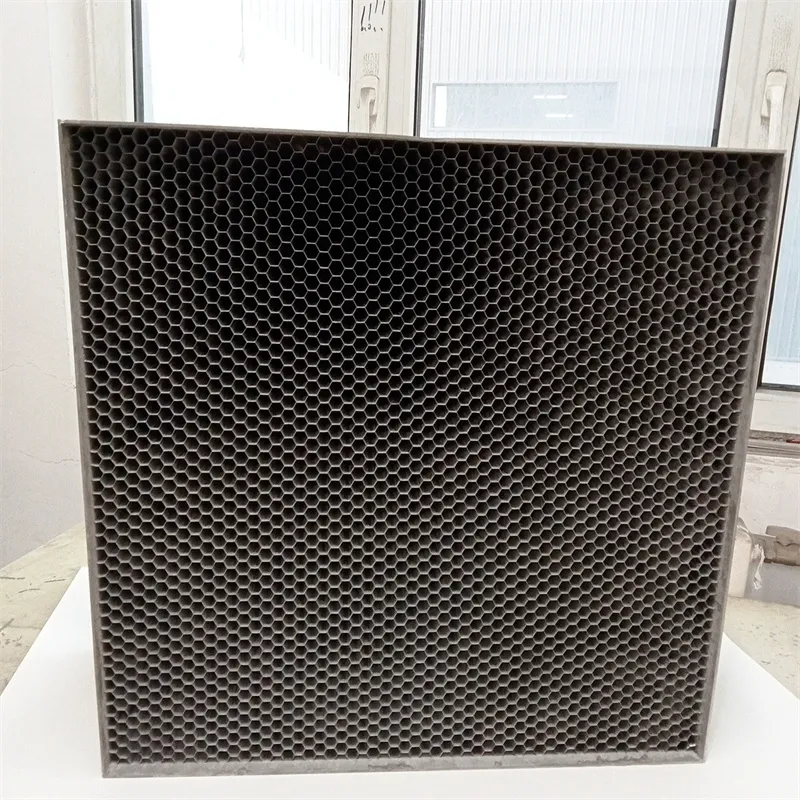

stainless steel honeycomb panel

Stainless steel honeycomb panels have become increasingly popular in the construction and design industries due to their exceptional strength, durability, and aesthetic appeal. These panels are constructed with a core layer designed in a honeycomb pattern, sandwiched between two outer sheets of stainless steel. This unique structure not only provides a high strength-to-weight ratio but also offers significant advantages in terms of environmental impact and longevity.

Key industry players consistently emphasize the importance of choosing high-quality stainless steel panels from reputable manufacturers. Ensuring the use of top-grade materials and stringent manufacturing processes enhances the panels' performance and longevity. Companies offering these panels typically provide extensive warranties, underscoring their commitment to quality and customer satisfaction. Recent advancements in manufacturing technology have further improved the efficiency and versatility of stainless steel honeycomb panels. Innovations such as laser cutting and precision welding have minimized waste and allowed for more complex design capabilities. These technological strides continue to push the boundaries of architectural possibilities, from intricate design motifs to large-format applications without compromising structural integrity. Incorporating stainless steel honeycomb panels in projects also demonstrates a commitment to high standards of safety and innovation. Their fire-resistant properties provide an extra layer of protection, crucial in public buildings and infrastructures where safety is non-negotiable. This aligns with global trends towards stricter building codes and standards aimed at safeguarding human lives and assets. For professionals seeking cutting-edge solutions that blend form with function, stainless steel honeycomb panels represent an ideal choice. Their combination of strength, aesthetic potential, and environmental benefits offers an unrivaled solution matched by few other materials. Choosing these panels for your next project not only supports modern architectural aesthetics but also aligns with sustainable development goals and long-term value creation.

Key industry players consistently emphasize the importance of choosing high-quality stainless steel panels from reputable manufacturers. Ensuring the use of top-grade materials and stringent manufacturing processes enhances the panels' performance and longevity. Companies offering these panels typically provide extensive warranties, underscoring their commitment to quality and customer satisfaction. Recent advancements in manufacturing technology have further improved the efficiency and versatility of stainless steel honeycomb panels. Innovations such as laser cutting and precision welding have minimized waste and allowed for more complex design capabilities. These technological strides continue to push the boundaries of architectural possibilities, from intricate design motifs to large-format applications without compromising structural integrity. Incorporating stainless steel honeycomb panels in projects also demonstrates a commitment to high standards of safety and innovation. Their fire-resistant properties provide an extra layer of protection, crucial in public buildings and infrastructures where safety is non-negotiable. This aligns with global trends towards stricter building codes and standards aimed at safeguarding human lives and assets. For professionals seeking cutting-edge solutions that blend form with function, stainless steel honeycomb panels represent an ideal choice. Their combination of strength, aesthetic potential, and environmental benefits offers an unrivaled solution matched by few other materials. Choosing these panels for your next project not only supports modern architectural aesthetics but also aligns with sustainable development goals and long-term value creation.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025